Lots de petite taille – Diminution des changements d'outils grâce aux outils combinés

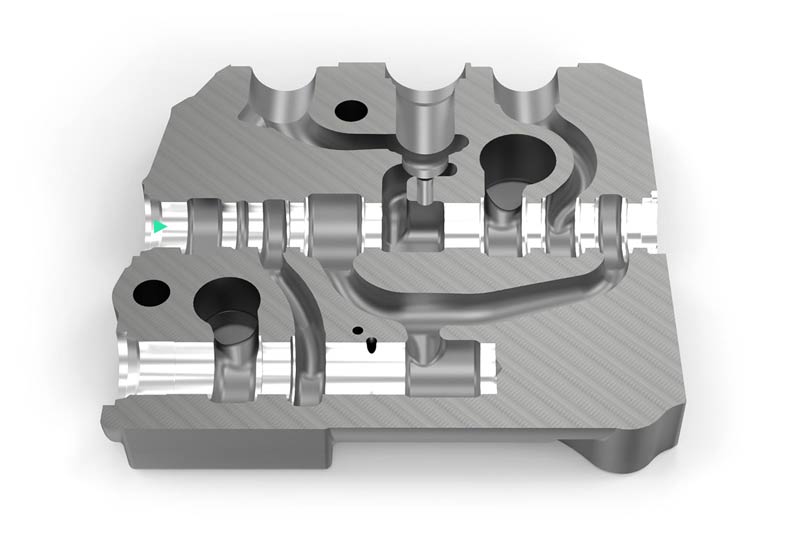

Corps de valve EN-GJL-300 – Alésage de tiroir

Situation initiale du client

- Petits lots

- Possibilité de régler l’outil

- Changement d'outil trop fréquent/fréquent

- Taux horaire élevé des machines

- Frais élevés en raison du processus de pierrage

Particularités de la solution

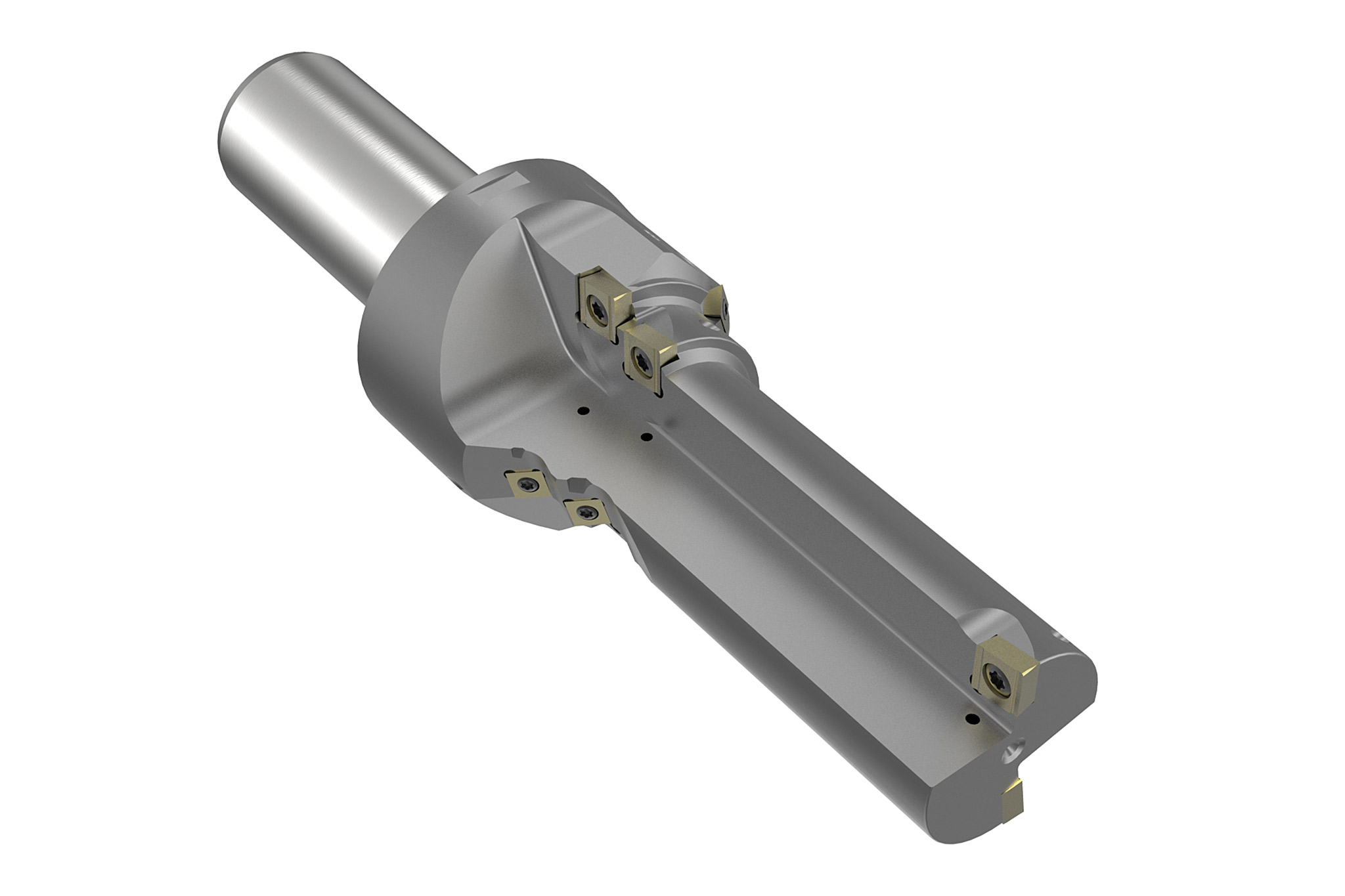

- Changement d'outil réduit grâce à un outil d'alésage à plusieurs niveaux avec des plaquettes amovibles

- Le contour peut être usiné en une seule « passe »

- L'outil d'alésage de précision produit une qualité d'alésage maximale et compense le décalage axial des alésages grâce à l'ébauche de deux côtés

Alésage de tiroir

1. Perçage pilote et alésage

- Outil d'alésage à plusieurs étages avec plaquettes radiales et tangentielles

- Ébauche du trou de tiroir et finition des contours en une seule passe

2. Usinage des arêtes de commande

- Outil profilé en carbure monobloc

- Précision et qualité de surface maximales des arêtes de commande

- Arêtes de commande définies sans éclatements

3. Alésage de précision

- Outil d'alésage de précision avec plaquettes et patins de guidage

- Idéal pour les usinages d'oblongs de perçages très précis et longs

![ANNUAL PRODUCTION COSTS OF THE COMPENSATOR BORE [€]](/medias/sys_master/root/h31/h1c/9043461046302/Grafiken_EN-14/Grafiken-EN-14.jpg)

Avantages

- Processus adapté de manière optimale grâce à une solution avec outil d'alésage à plusieurs niveaux avec plaquettes amovibles, usinage des arêtes de commande et alésage de précision

- Précision et fiabilité des processus maximales

- Réduction des efforts de pierrage et donc des coûts