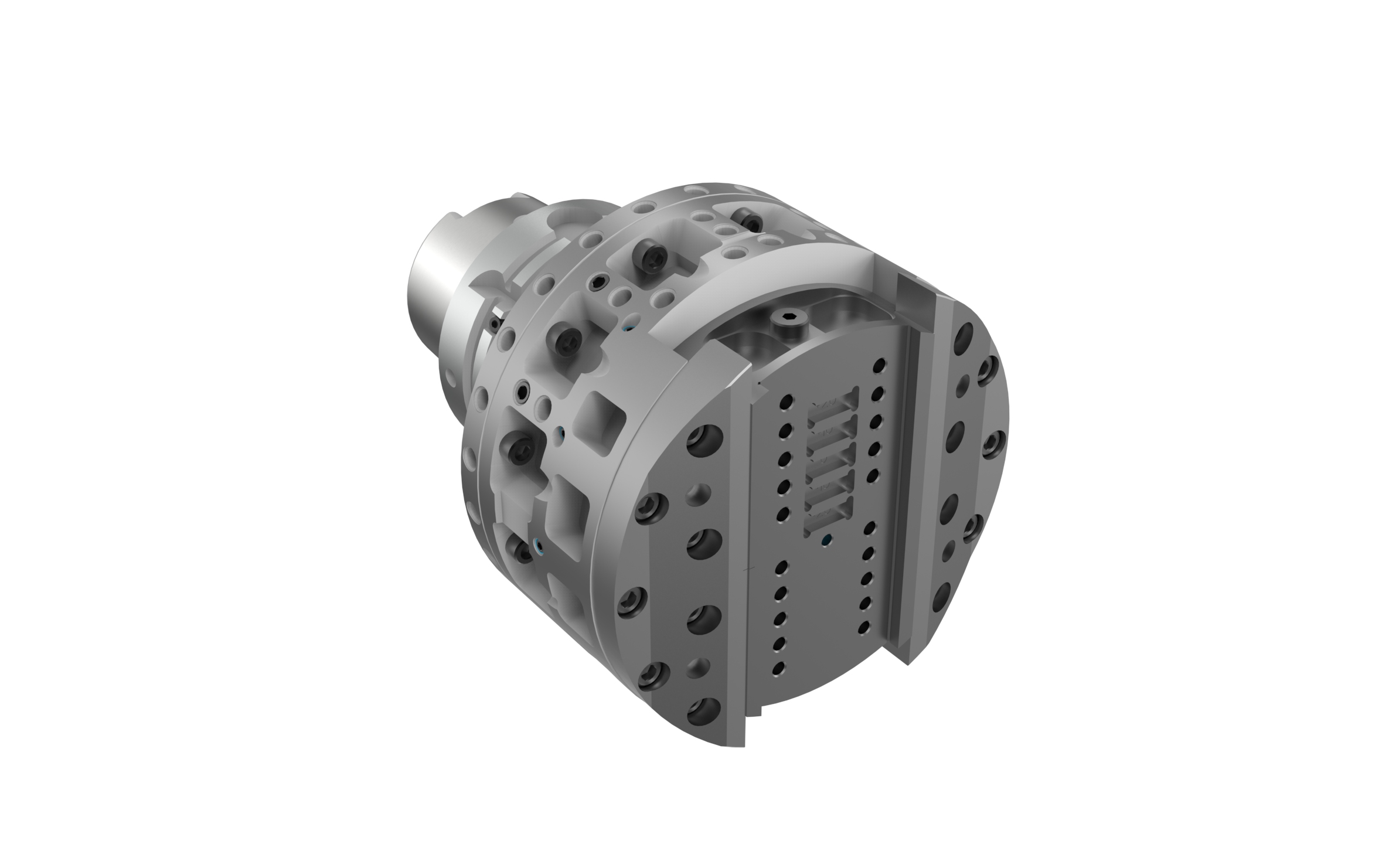

Corps de servomoteur

Solutions d'application grâce à la technologie de modulation

Corps de servomoteur en AlSi10

Situation initiale du client

- Exigence en matière d'usinage de profils complexes avec un seul système d'outillage : surfaçage, chanfreinage, usinage du diamètre et usinage conique 1:50 (1,1146°)

- Exigence élevée en matière de tolérances de forme, de position et IT8

Particularités de la solution

- Les usinages intérieurs et extérieurs sont réalisables en toute sécurité avec une coaxialité optimale

- Possibilité d'un changement d'outil automatique

- Réglage des outils sans incidence sur le temps de fonctionnement principal grâce aux outils jumeaux

- Préréglage du dispositif de réglage possible grâce à un processus flexible

- Possibilité d'utiliser des outils standard (par exemple, des forets ou des fraises) sans changer de broche

- Technologie de plaquettes amovibles permettant de réduire le coût des matériaux de coupe

Points forts de l'outil

- HSK-A100 avec axe U (axe de rotation)

- Usinage intérieur et extérieur avec outil coupant

- Course de surfaçage de 56 mm

- Plage de diamètre pour l'usinage : 112 mm

- Outil coupant décalable sur cinq niveaux pour une plage de diamètre maximale

- Approvisionnement optimal en liquide de coupe par alimentation interne en réfrigérant directement sur les arêtes de coupe

.pptx - PowerPoint/2023-11-29-14-00-36-Aussteuern-Kundenpr-sentation-EN-1-.pptx-PowerPoint.jpg)

Avantages

- Profils complexes et exigences de précisions réalisables grâce à un seul système d'outillage

- Faibles coûts en matériau de coupe dans le processus de fabrication en série étant donné que seuls deux types d'outils sont requis pour toutes les variantes

- Fiabilité maximale des process en cas de variance élevée étant donné que les profils et la forme conique 1:50 (1,146°) peuvent être programmés et corrigés librement

- Le partenariat technologique avec MAPAL permet de regrouper toutes les étapes d'usinage