Large series with solid and adjustable tools

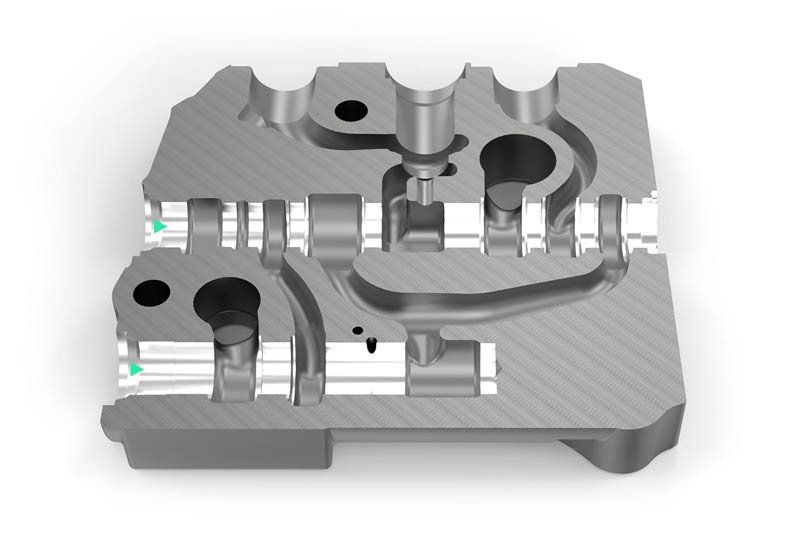

Valve housing EN-GJS-400-15 – spool bore and compensator bore

Initial situation at the customer

- Large-scale series

- Tool setting desired

- High machine hourly rates

- High costs for subsequent single pass honing

Special features of this solution

- 個々の工具が理想的に組み合わされ、ホーニング工程を短縮するための最適な前提条件を保証

- 部品によってはホーニング加工を省くことが可能

スプール穴

1. ボーリング

- パイロット加工とボーリング加工の連携による最適な前加工

- 多刃リーマの技術と適切なクーラント供給により最適な切り屑処理と再研削が可能

- 特殊なボーリング形状により、キャビティのリング形成を回避 → リング除去のためのコストが発生しない

2. コントロールエッジ加工

- 超硬ソリッドプロファイルツール

- 高い精度と品質のコントロールエッジ加工を実現

- 破損のないコントロールエッジ

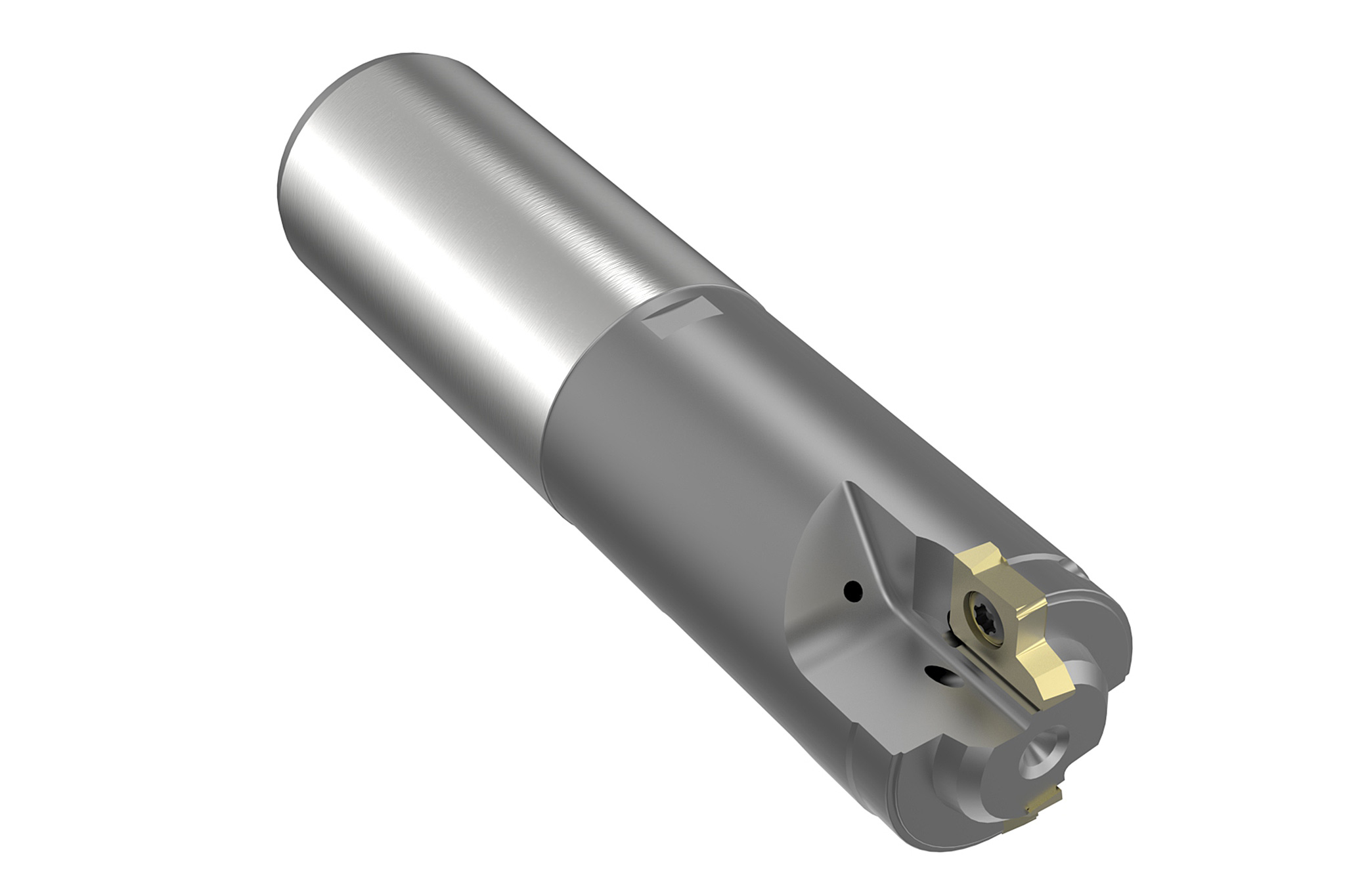

3. ファインボーリング加工

- EasyAdjustシステムとガイドパッド付きファインボーリングツール

- 信頼性の高い仕上げ加工と容易な取り扱い

- 理想的なトラッキングによる最適なシリンダー形状

流量制御穴

1. ボーリング

- 6つのガイドマージンを備え、特殊なリード形状の超硬ソリッドガンボーリング工具。

- ストレート穴、加工穴全長にわたって理想的な切り屑の流れとガイドを実現。

- 1つの工具で2つの加工を行うことによる生産外時間の短縮

2. 形状加工

- 精密成型付き2枚刃ガンボーリング工具

- 信頼性の高い形状加工

- 容易な取り扱いで、工具材料費を低減

3. ファインボーリング加工

- EasyAdjustシステムとガイドパッド付きファインボーリングツール

- ホーニングが不要な容易な取り扱いで頼性の高い仕上げ加工

- 理想的なトラッキングによる最適なシリンダー形状

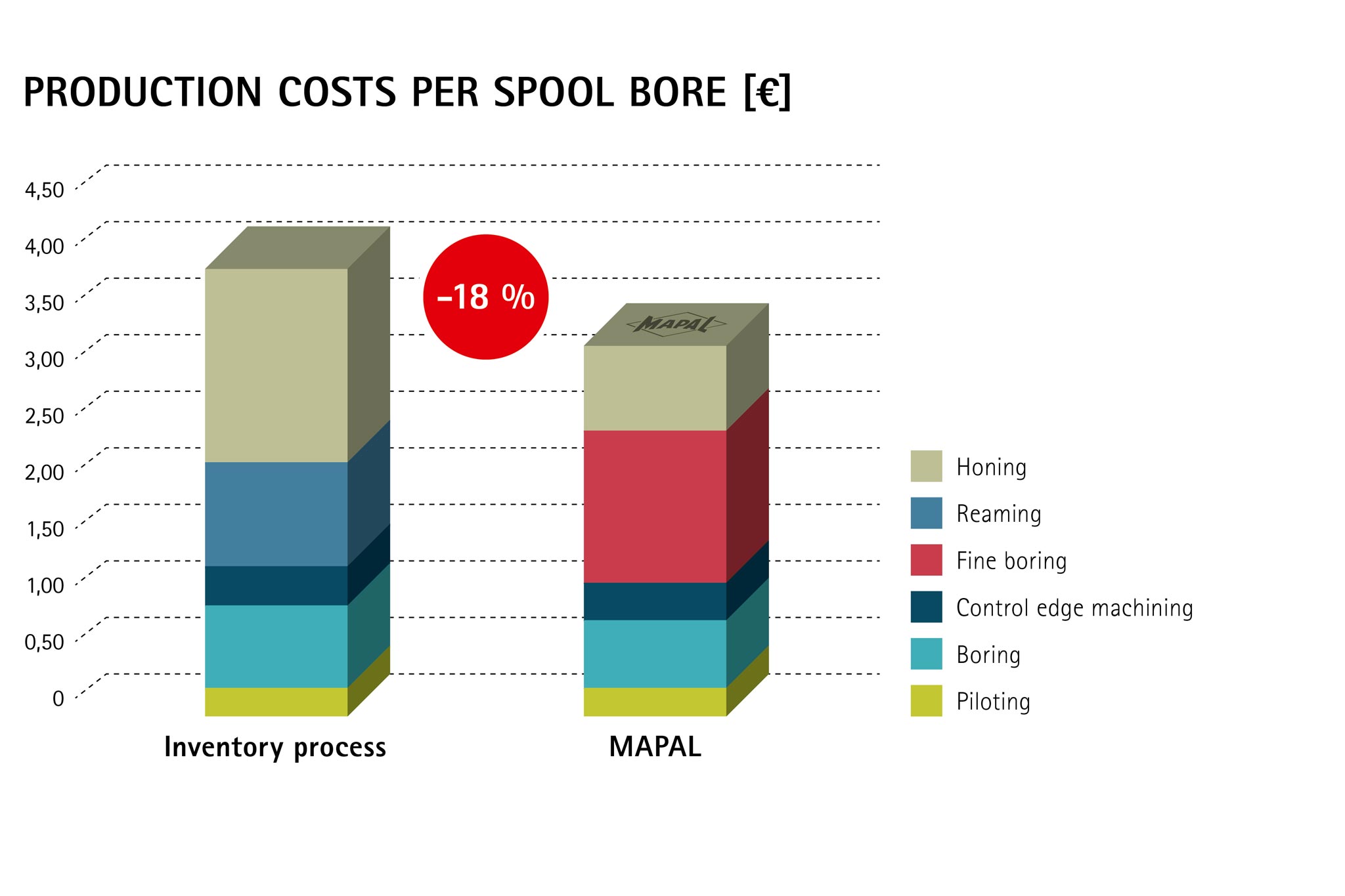

利点

- 費用の高いスプール穴のホーニング工程を短縮

- 加工穴当たりのツールコストが低減

- お客様との連携で巧みなエンジニアリングによる生産外時間の短縮

- 流量制御穴のホーニング加工が不要になり、大幅なコストダウンが可能

![ANNUAL PRODUCTION COSTS OF THE COMPENSATOR BORE [€]](/medias/sys_master/root/h6c/h6e/9043460718622/Grafiken_EN-13/Grafiken-EN-13.jpg)