04.05.2023

News from the reaming and fine boring sector

MN reamers with short delivery times, new cutting materials for special requirements

The PVD coating has a fine crystalline microstructure, combining high levels of hardness and ductility. The cutting materials are thermally very stable and offer impressive high-temperature stability and coating adhesion. To create an optimum surface in through bores and blind bores, the PVD coating is deposited in the µm range. This ensures the cutting edges retain their sharpness.

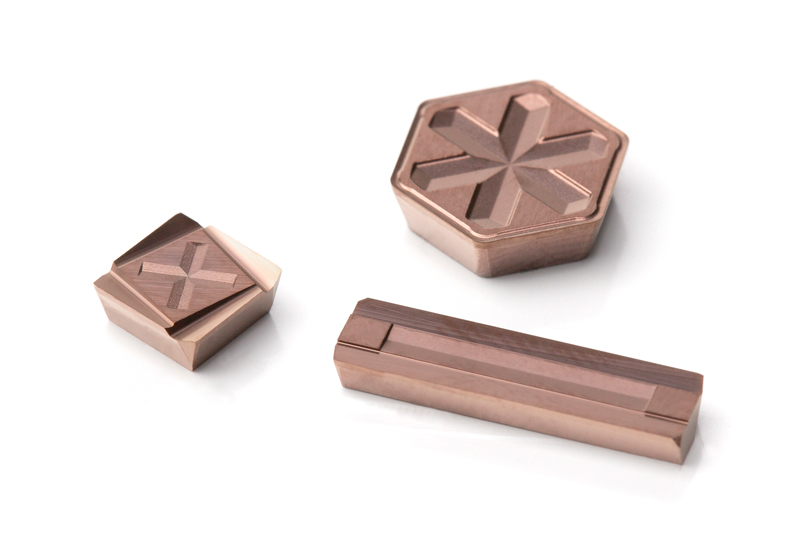

The new cutting materials are used for market launch in the reamers in the MN series by MAPAL, among others. These tools represent the utmost accuracy and are now also ideally suitable for use in hard reaming applications as well as reaming stainless steel thanks to the new cutting materials. They operate according to the MAPAL principle – with one insert and a guide pad opposite. Depending on the application, the guide pads are made from carbide, cermet or PCD.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342