01.03.2018

Smaller, more heat resistant more and more individual - application focus clamping technology from MAPAL

Product manager Jochen Schmidt about the benefit of clamping technology in cutting appiclations

The role of clamping technology has changed. From mere holders of the tools and mass produced parts, the chucks have increasingly developed into application- oriented top performers. Because in order to make the best possible use of the tool and the machine, the chuck plays a decisive role. Completely new possibilities in this sector have been opened up by additive manufacturing – for which MAPAL has a clear advantage as a technology leader. Jochen Schmidt, Product Manager Clamping Technology, reports on how this came about and how clamping technology is further developing.

Clamping technology and MAPAL – what made a manufacturer of precision tools to be also active in this sector?

Jochen Schmidt: Machining and its results are always a sum of different factors. This means

that for a tool to achieve its maximum performance capability, its clamping system must also

be optimally designed for the corresponding conditions. As a solution provider in the machining sector, it was therefore logical for MAPAL to add chucks to the portfolio.

From today’s viewpoint – has this decision paid off?

I can answer this clearly: Yes! Today we supply everything for the machining process from a

single source. We see ourselves as a technology leader in the clamping technology sector with the advantages acquired with additive manufacturing.

What role does additive manufacturing play in clamping technology at MAPAL?

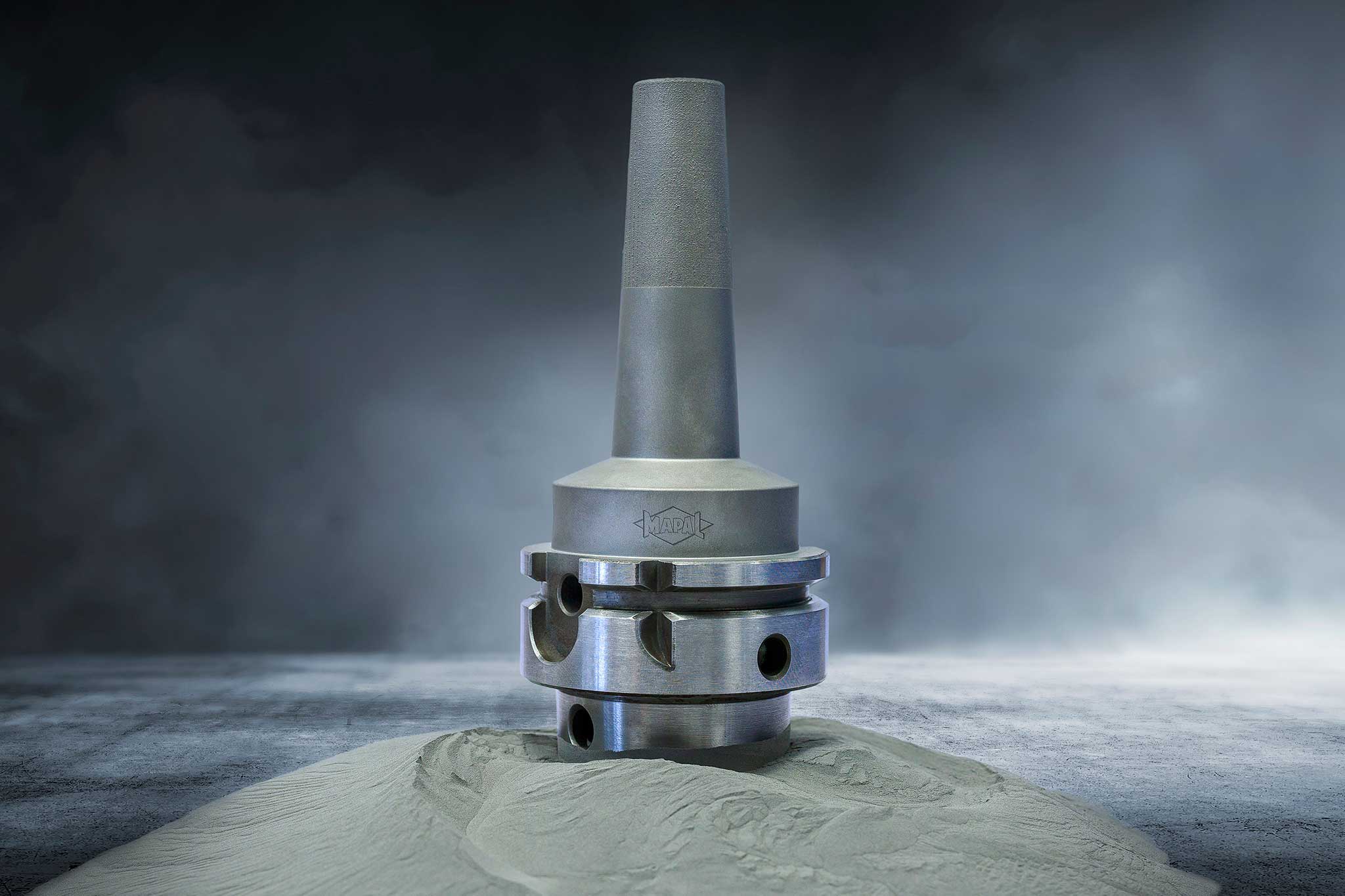

Generally over the last few years we have set a trend in clamping technology towards individual customer solutions. Thanks to additive manufacturing, we have been able to implement concepts for our customers that previously could not be realised. For the optimum process, the clamping point must often be brought closer to the cutting point than was previously possible. To achieve this, chucks are needed that are extremely narrow without power loss. MAPAL complied with this requirement with hydraulic chucks with narrower contours, among others. They allow hydraulic clamping technology to be used where previously only shrink chucks were used. Together with more precise run-out and highly accurate clamping, this offers additional advantages for the customer: On the one hand, handling hydraulic chucks is significantly easier and tools can be clamped more quickly. On the other hand, the cost-intensive periphery concerning the shrink chucks can be dispensed with.

How exactly are the chucks produced?

The functional range is applied to the conventionally produced tool body by selective laser

melting. In this way, we also manufacture hydraulic chucks with a narrow contour for direct

clamping of tools with a diameter from 3 mm.

Apart from the geometries that previously could not be realised, are there other advantages that arise from additive manufacturing?

As a result of additive manufacturing, our hydraulic chucks can be reliably used at operating

temperatures of up to 170 °C because thanks to this production method, the temperature-critical soldering point between the clamping sleeve and tool body can be dispensed with. This is all the more important because dry machining makes up an increasingly large share of production processes due to environmental aspects amongst others. For thermal loads that exceed this temperature limit, for example for friction stir welding, with additive manufacturing we have succeeded in integrating a separate cooling system in the chuck. This means that the user can work reliably with our chucks even at significantly higher machining temperatures.

Is additive manufacturing at all suitable for series production or just for customer-specific special clamping systems?

At MAPAL we have already been mass manufacturing with our machines since 2014. Today we operate several 3D printers at two sites. But naturally additive manufacturing is also perfectly suited for customer-specific projects.

What are the costs?

Basically it’s like this: The completely new concepts for clamping technology that we implement with additive manufacturing provide our customers with clear added value. What may appear to be expensive at first glance, can turn out to be very profitable on closer inspection and with the aid of amortisation calculations.

A very impressive example of this is an application that requires a long projection length of the tool due to the dimensions. Here there are now two options. Either the customer applies a long chuck optimised for the application in combination with a standard tool. Or the customer uses a standard chuck and requires a long special tool. If one considers the service life of the tool and the chuck, in this case the higher procurement costs of the special chuck will already amortise after eight tool changes.

What other developments do you anticipate in the future in the clamping technology sector? What are the trends?

In my opinion the sensors in tool holders will primarily play a significant role in the future. Because in mass production, more and more chucks are required that can be integrated in intelligent production structures with a high level of automation. And smart clamping devices with corresponding sensors can provide important data for machining as a link between machine and tool.

What benefits are to be gained from this data?

For example, if the user knows the forces at the tool using this data, he can draw conclusions concerning the remaining tool life. He can therefore use his tools over a longer service life or conversely replace them before a tool break and therefore possible damage to the component. In addition scheduling sizes can be determined more accurately and a digital service for customers can be expanded thanks to the relevant data.

How will the role of clamping technology change by collecting this data?

The essential role of clamping technology will not change. A chuck always clamps a tool. A

lot of other things will change – this means the options for evaluation and precise coordination of the individual factors will increase. As with the tools, we also offer our customers numerous services beyond “merely” clamping the tools. This includes the chucks already mentioned that are precisely matched to the relevant application. Incidentally they are also used in quite exceptional sectors for MAPAL.

For example?

Our chucks are now used for the manufacturing of sewing machines and hydroelectric turbines. We have developed many new fields of application whose specific requirements are met using our chucks. I am particularly thinking of customers from the mould and die making field that use our HighTorque Chuck (HTC) with narrow contour in many cases.

You also presented the hydraulic chuck with narrow contour last year for the direct clamping of small diameters. What was the response to this presentation?

Very good. These chucks open doors for us in many applications – including in the electronics and medical industry as well as the jewellery and watch industry. We have continued to work intensively and research in this field of miniaturisation. We will present the results in September at the AMB in Stuttgart.