Competenza nell'azionamento

La Gamma di prodotti comprende utensili

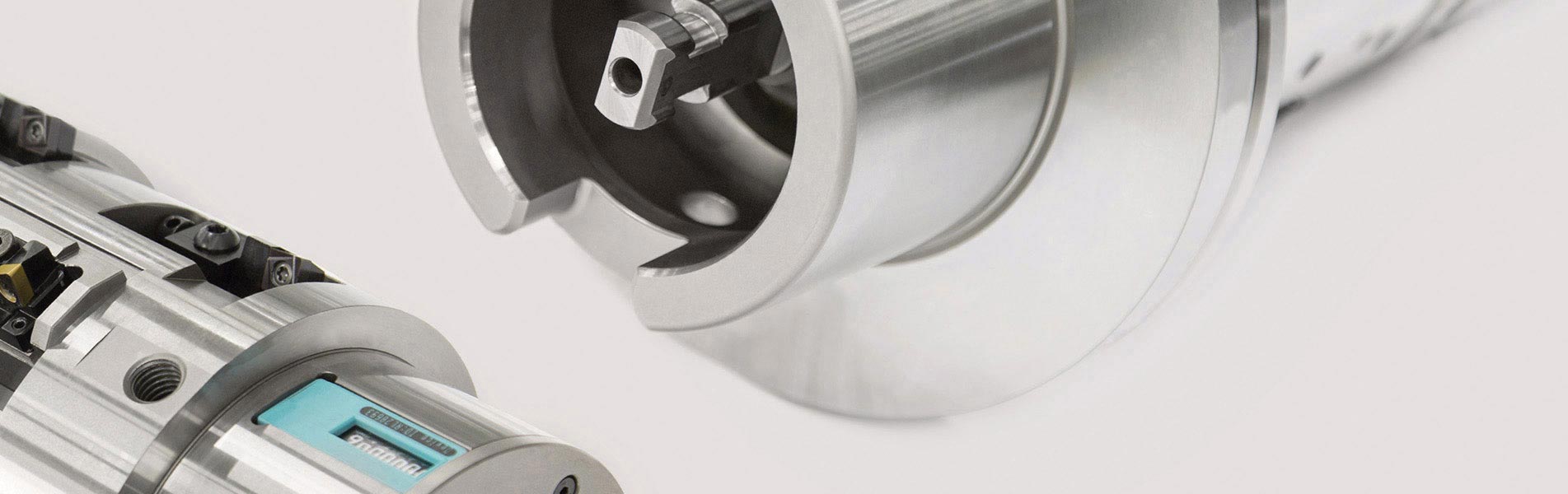

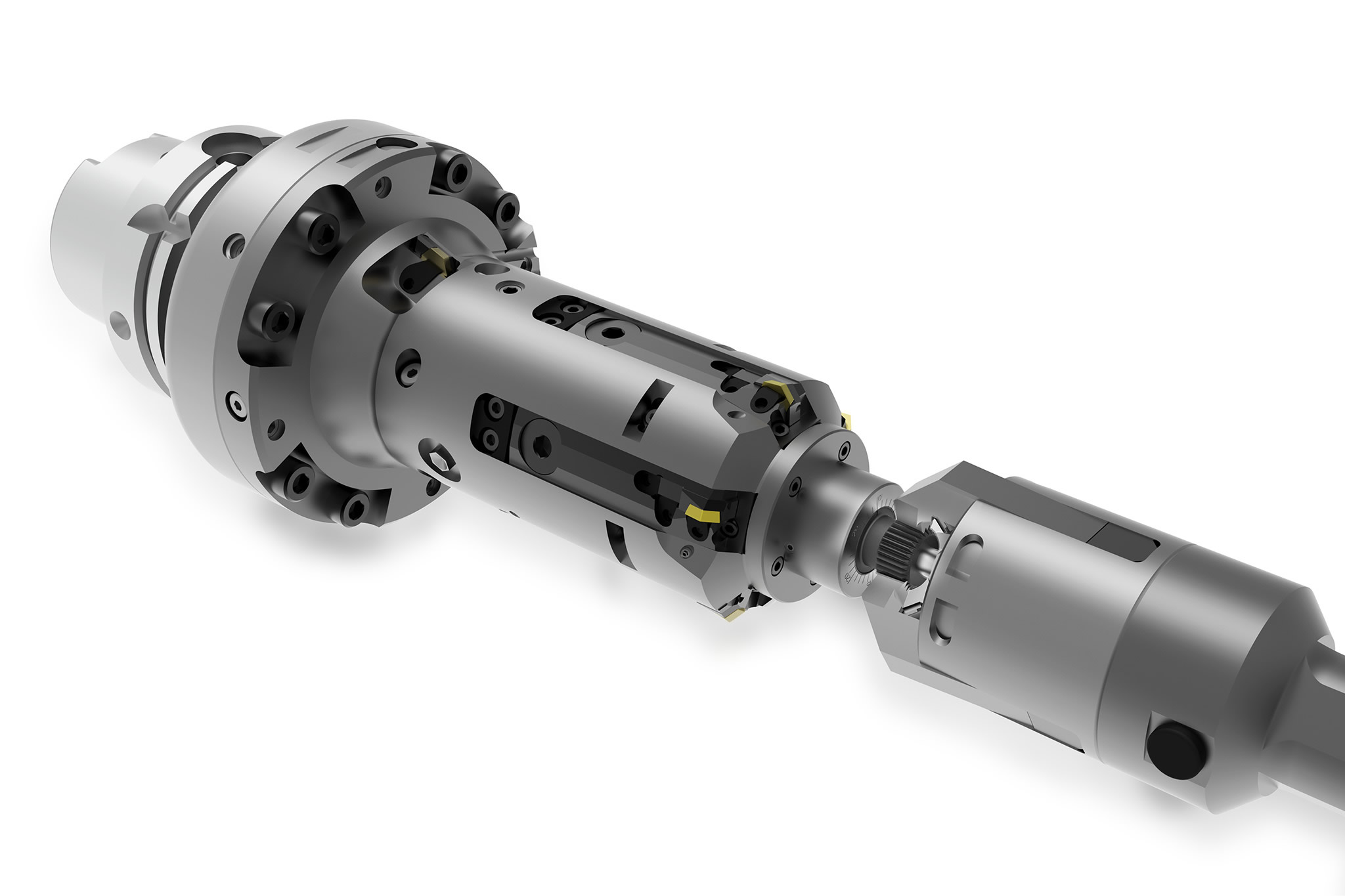

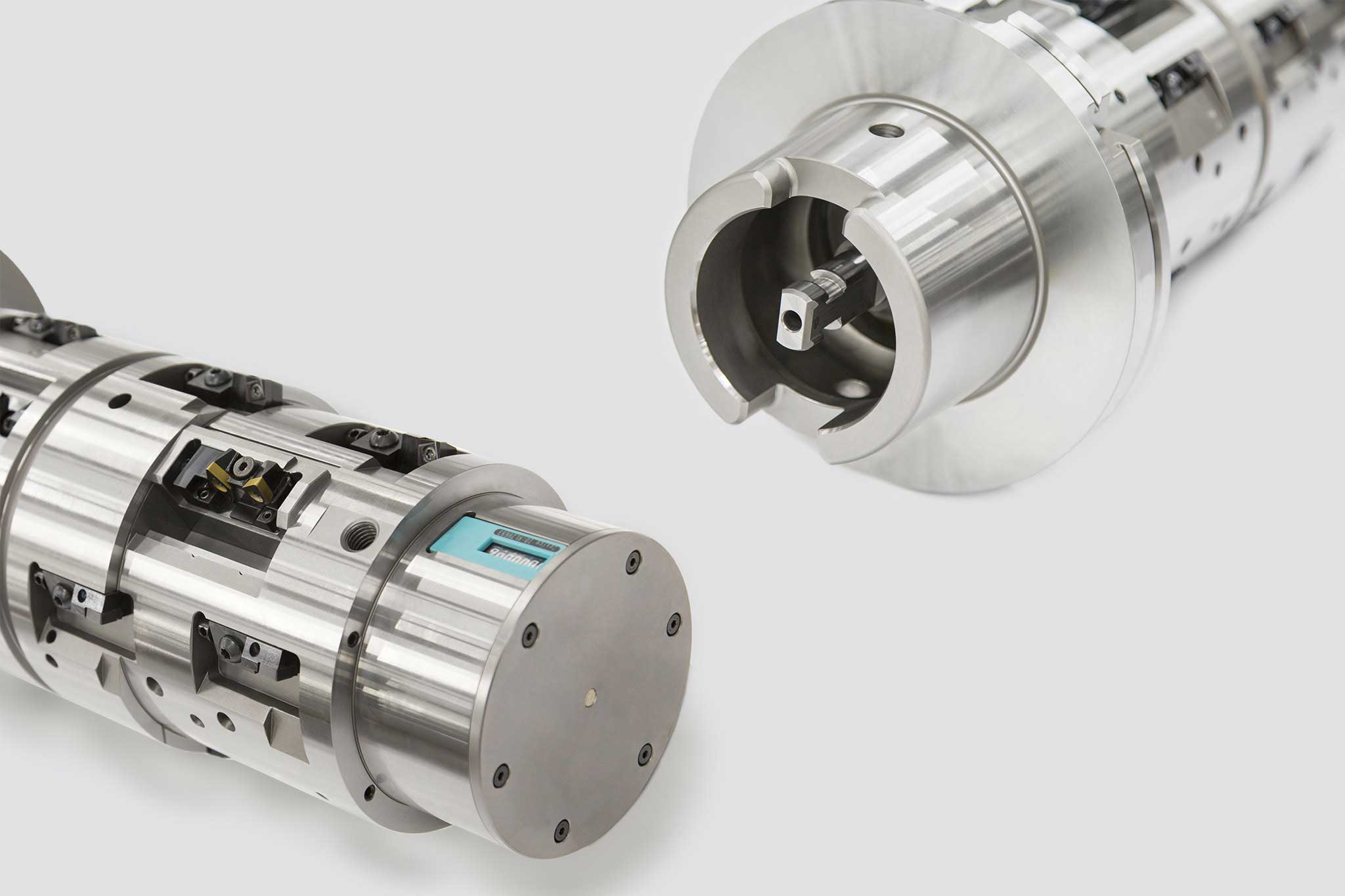

- di comando meccanici, azionati dalla macchina per mezzo di barre di trazione/ pressione o da sistemi con asse U, nonché utensili a comando NC, come il sistema

- di utensili meccatronici TOOLTRONIC, particolarmente flessibile e pensato per macchine senza unità di avanzamento aggiuntiva.

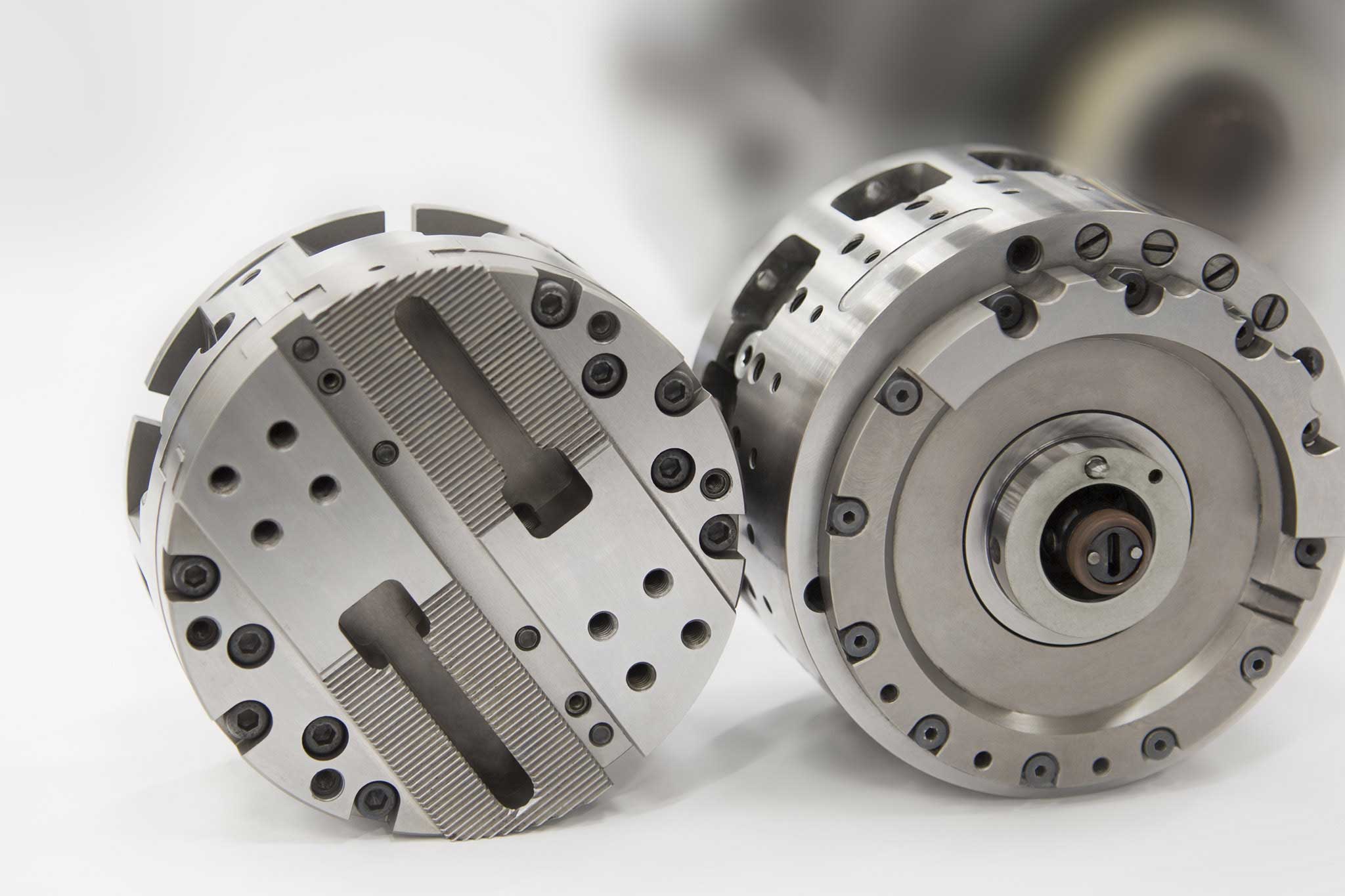

Il team di ingegneri MAPAL, esperto ed altamente specializzato, lavora a stretto contatto con il cliente per elaborare la soluzione ottimale per lo specifico lavoro di truciolatura. La meccanica pregiata e perfettamente sincronizzata, nonché l'elevato numero di elementi diversi presenti all'interno dell'utensile di comando richiedono la massima precisione e la massima cura in ogni singola fase di produzione. Al fine di garantire l'assoluta precisione degli utensili, alla MAPAL il loro montaggio avviene esclusivamente a mano. Per poter eseguire la messa in funzione degli utensili presso il cliente nel modo più rapido ed efficiente possibile, gli utensili di comando complessi vengono prima testati in modo approfondito, in condizioni di utilizzo reali e con carichi estremi. La messa in funzione presso il cliente viene eseguita a cura di uno specialista in truciolatura MAPAL.

Quando è utile l'azionamento?

Panoramica del prodotto

Tipologie di drive per l'input e l'output

TOOLTRONIC

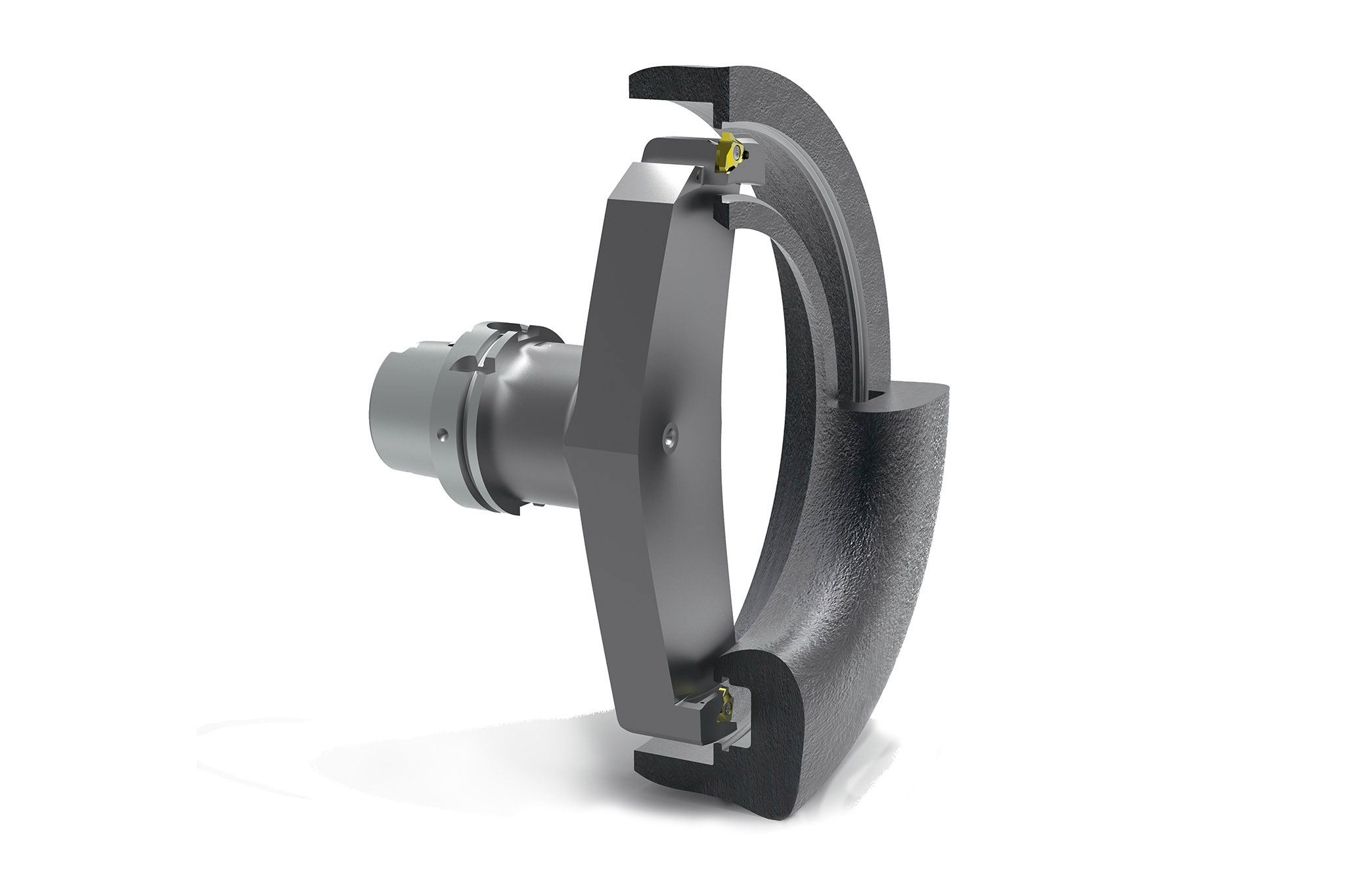

Teste a sfacciare

Bareni

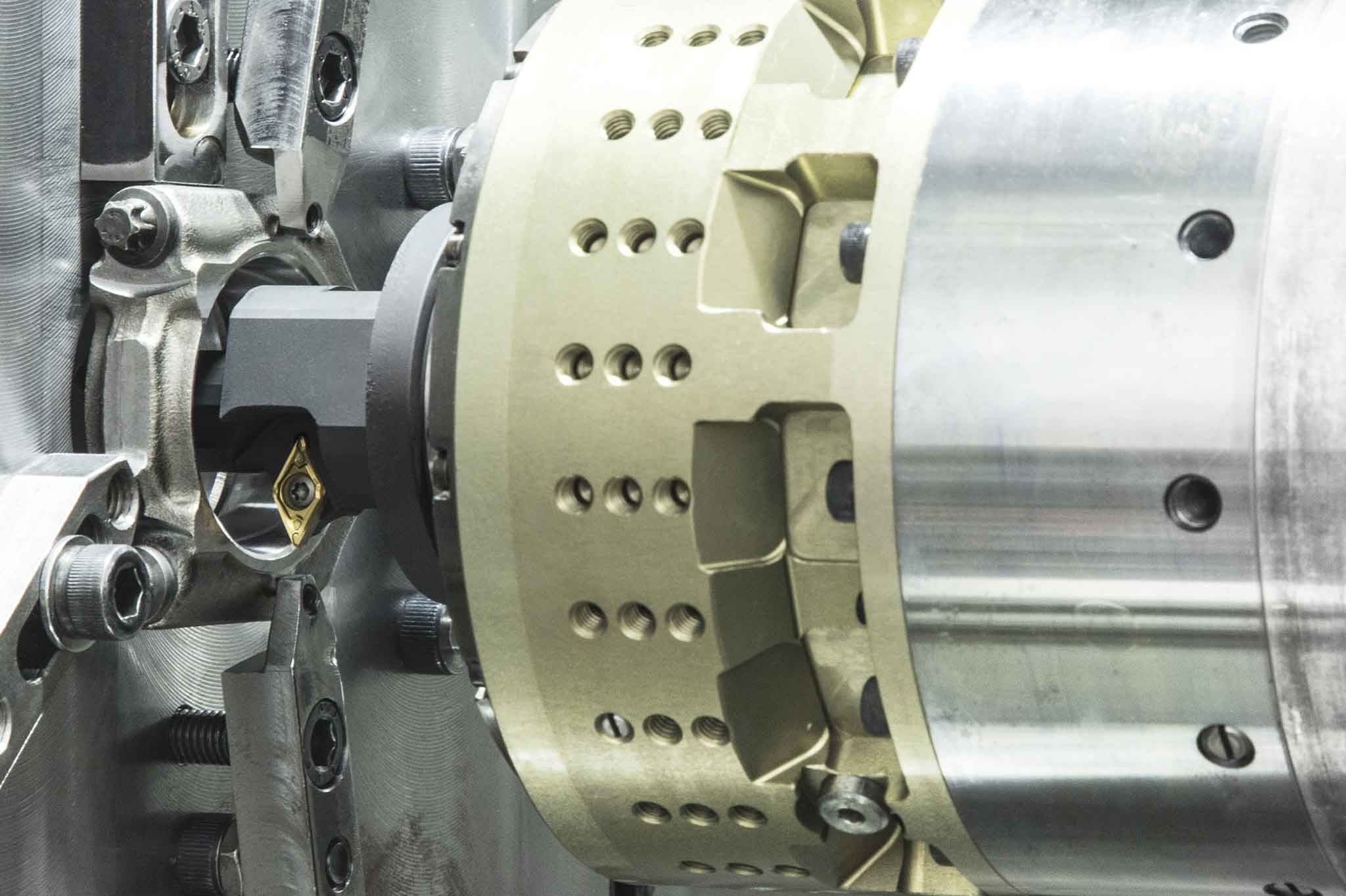

I bareni sono utensili per la lavorazione specifica di raccordi dei cuscinetti negli involucri. L'utensile viene inserito nel dispositivo (serraggio utensile) attraverso almeno un cuscinetto di guida. I diversi taglienti dell'utensile consentono la lavorazione contemporanea di più traversini. Una barra di trazione/pressione opzionale consente la lavorazione piana aggiuntiva del relativo cuscinetto e/o il sollevamento dei taglienti, al fine di compensare l'eventuale usura dei taglienti stessi.

I bareni vengono impiegati nella lavorazione di fori dei cuscinetti di albero motore e albero a camme. Sono considerati lo strumento più preciso per la realizzazione di questi fori nell'alloggiamento del gruppo cilindri.

Altre applicazioni

Servizio per utensili di comando

Ingegneria - versione - messa in funzione - manutenzione

Per quanto riguarda il settore degli utensili di comando, la MAPAL propone un servizio di consulenza relativo all'intera gamma di prodotti. Nel corso dei primi colloqui, il collaboratore del settore vendita recepisce le necessità e i desideri del cliente relativamente al processo di lavorazione, al fine di poter proporre il prodotto più adatto. In quanto specialisti in soluzioni speciali, proponiamo anche adattamenti specifici per le necessità del cliente, con impiego di componenti standardizzati. Al fine di poter programmare le scadenze per la manutenzione e di ridurre i costi del servizio, offriamo la possibilità di stipulare un contratto di servizio su misura.

Il team di assistenza MAPAL controlla gli utensili ad un intervallo di manutenzione prestabilito.

Manutenzione ordinaria e straordinaria dell’utensile semplificata grazie al display autarchico

L’integrazione di un chip di servizio munito di LED, per lo più installabile anche a posteriori, notifica mediante l’emissione di un segnale lampeggiante l'imminenza di un intervento. Viene inoltre conteggiato il numero delle ore di esercizio.