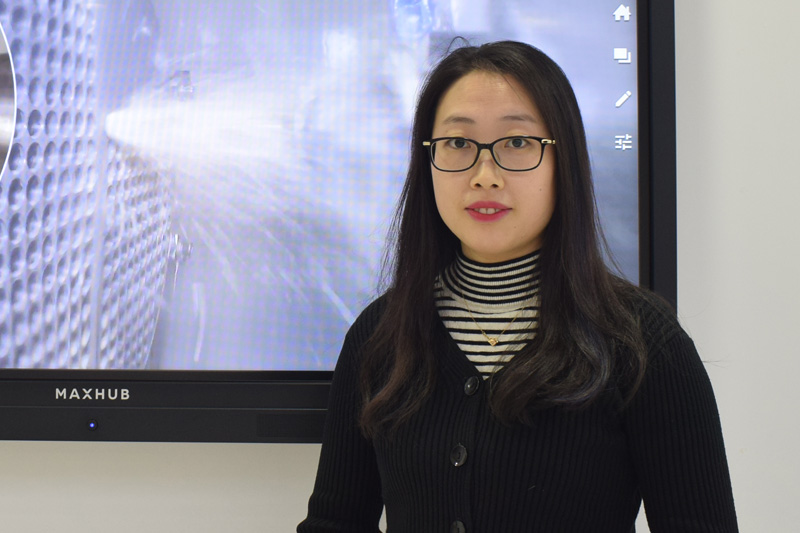

Our people: Adrien Lacour

As a team leader in the milling and turning department at MAPAL France S.A.S., Adrien Lacour’s workdays are full of variety.

Between being in the machine room and at the desk – a good team player must be able to play many positions. At the French site in Le Chambon-Feugerolles, Adrien Lacour acts as an important liaison between production and management for the milling and turning department.

“My responsibilities include material and tool procurement, preparing the manufactured parts for transfer to heat treatment, and organising my team’s shift schedule. I also work in manufacturing. I work pretty independently when it comes to overseeing my sector, so I have to know all the machines and their respective tolerances”, Adrien says, describing his sphere of activity at MAPAL S.A.S. France The head office at the Chambon-Feugerolles site, close to the city of Saint-Étienne, focuses on manufacturing multi-bladed reamers, drills and milling cutters made of solid carbide and PCD.

Working at MAPAL is Adrien’s first professional post. He was born in the Auvergne-Rhône-Alpes region. After his technical school leaving exam, he completed his Bachelor of Science, specialising in technical innovation and ecological design. He followed this degree up with two years of study in the industrialisation of mechanical processes. He began training as a turner at MAPAL in 2014 and became a permanent employee after completing his training. “Back then, I was looking for a company where I could work and study for a two-year vocational university programme that focused on putting theory into practice with a BTS technical diploma. I picked MAPAL because it offered me the perfect working environment with an organised and tidy workshop as well as the opportunity to discover the world of machining, which I didn't know anything at all about at the time”, Adrien remembers. He's just been promoted to team leader of the turning and milling department.

Setting the pace for production

Training on every machine

He was especially pleased about his promotion because of the trust that has been put in him and because he has been given tasks with great responsibility and creative leeway. He is also expected to attain additional qualifications and expertise in his new position. By undergoing training on several machines, he hopes to add even more strings to his bow. “The company has taught me how to use a wide variety of machines, which has built up my skill set. I can now use all of the machinery in the machining sector and also harness the software for computerised construction and manufacturing”, Adrien explains. He also quite enjoys hands on work on the CNC lathe and milling cutter if he's needed there.