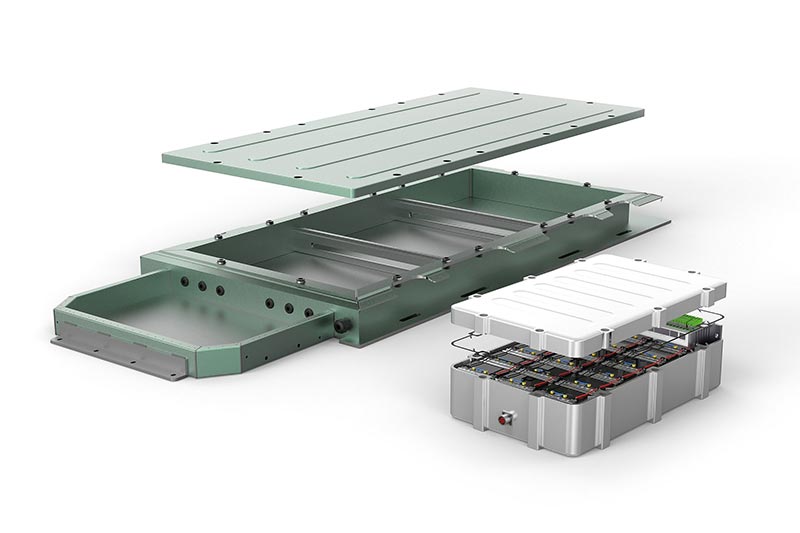

Electrified auxiliary units

As a result of electrification in the automotive industry, more and more drive tasks

of the internal combustion engines are being performed by electrified components.

By electrifying the auxiliary units, these components can be used as required and

depending on the load, and thus contribute to reduced energy consumption. They

stand out thanks to their high reliability and low noise emissions as well as excellent

energy efficiency.

of the internal combustion engines are being performed by electrified components.

By electrifying the auxiliary units, these components can be used as required and

depending on the load, and thus contribute to reduced energy consumption. They

stand out thanks to their high reliability and low noise emissions as well as excellent

energy efficiency.

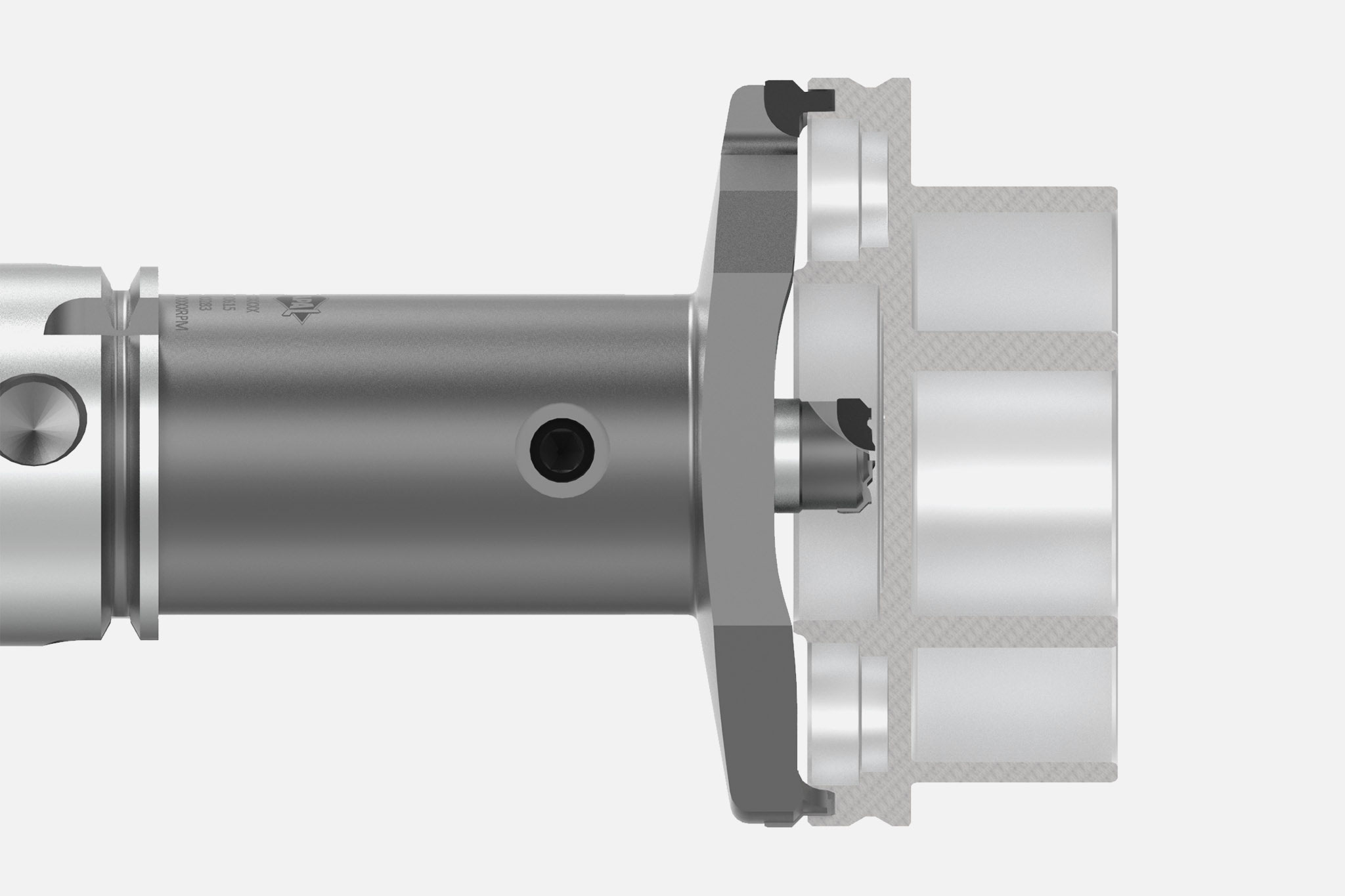

Auxiliary unit scroll compressor

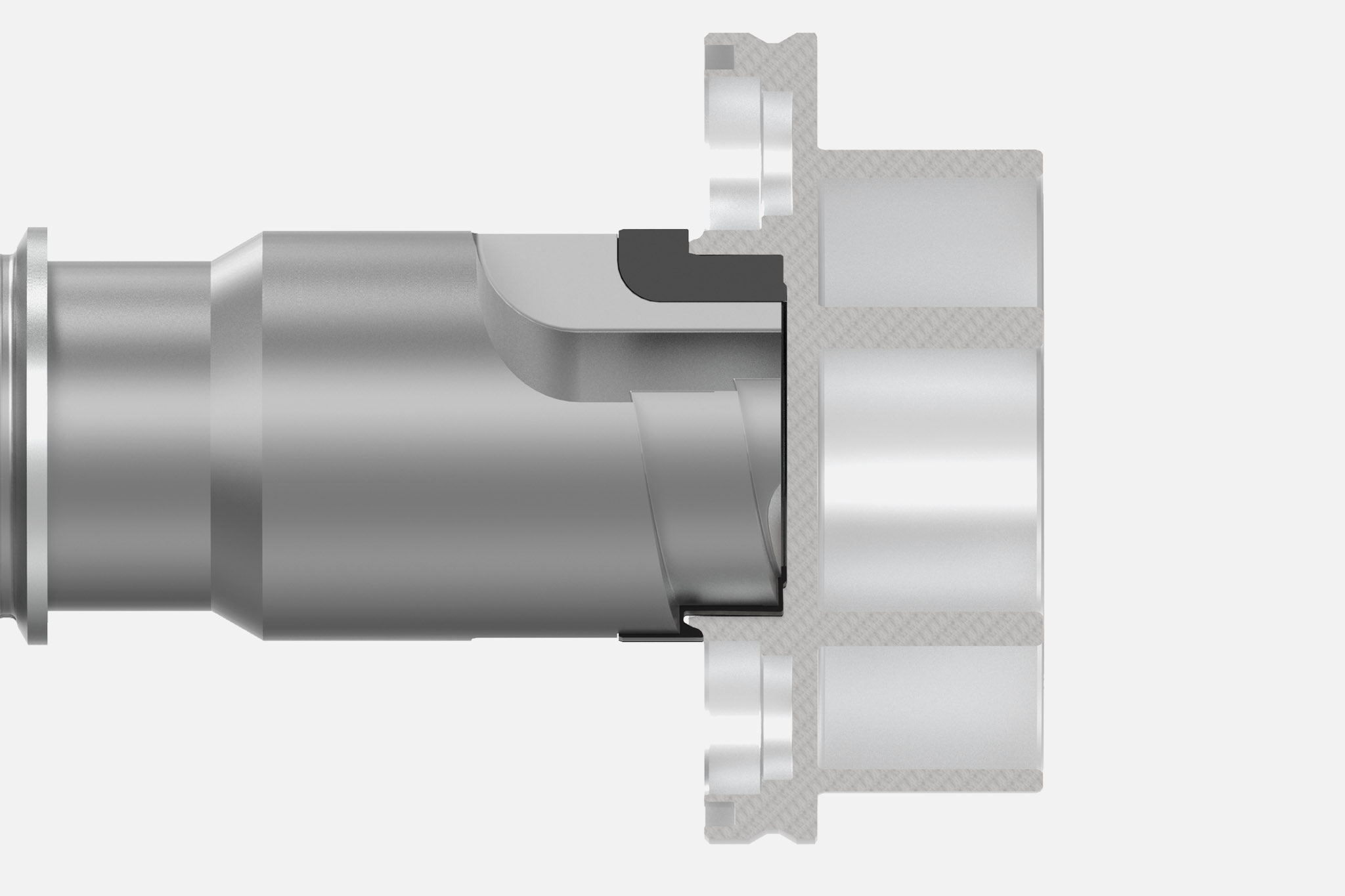

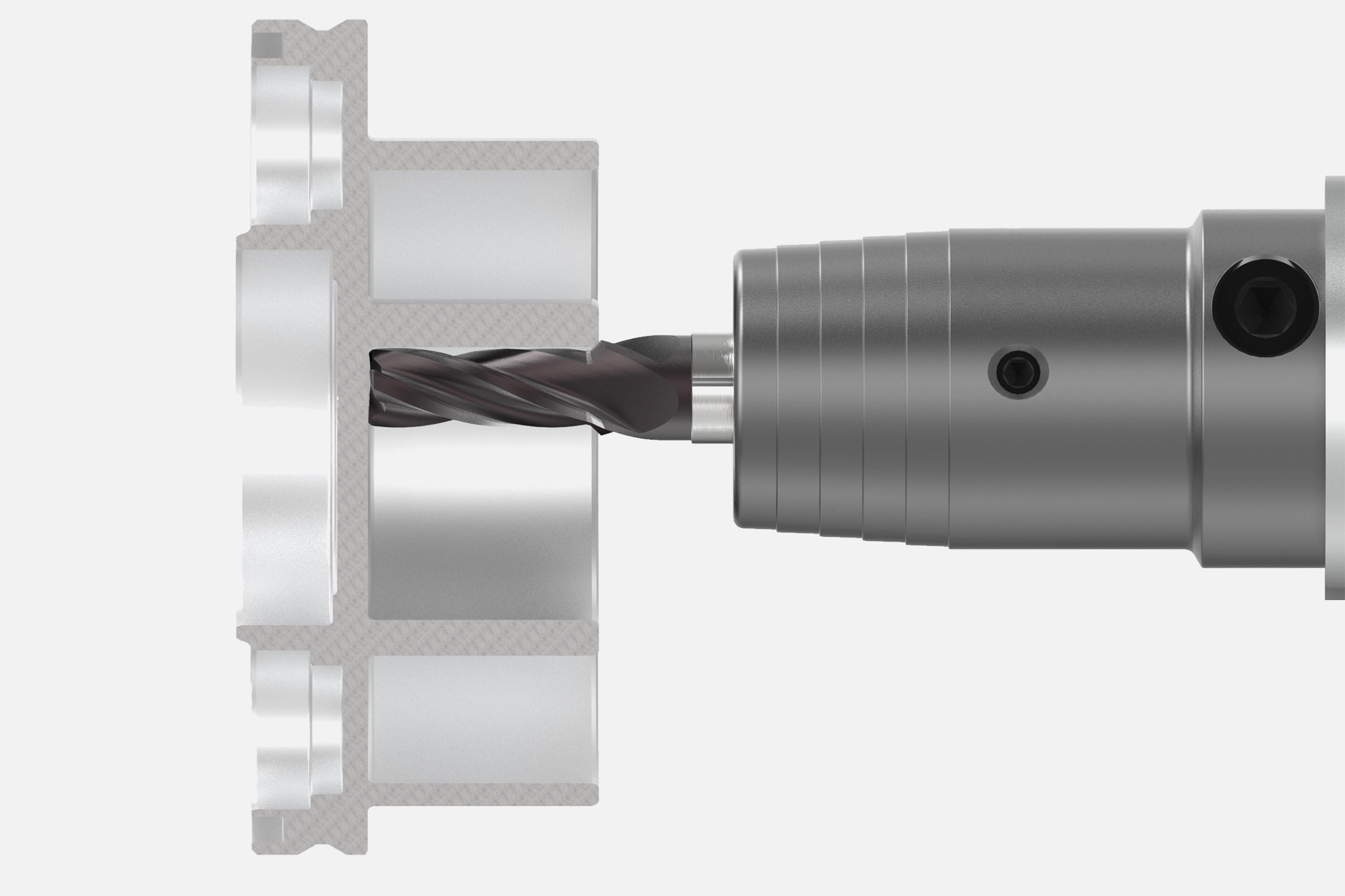

An example of an electrified auxiliary unit is the scroll compressor, which is used as an electric refrigerant compressor in thermal management. Three specific machining operations on an aluminium scroll compressor for use in an electrified vehicle are presented as examples.

FEATURES

- Core pieces orbit and fixed scroll

- Geometric accuracy and connection is paramount

- Exact positioning of the spirals to each other

MACHINING REQUIREMENTS

- High degree of shape accuracy of the spirals (≤ 20 μm)

- High perpendicularity of flanks to base surface (≤ 20 μm)

- Parallel alignment and flatness of ≤ 10 μm

- Surface roughness (Rz) in the single-digit range

- Perfect interaction between machine and tool