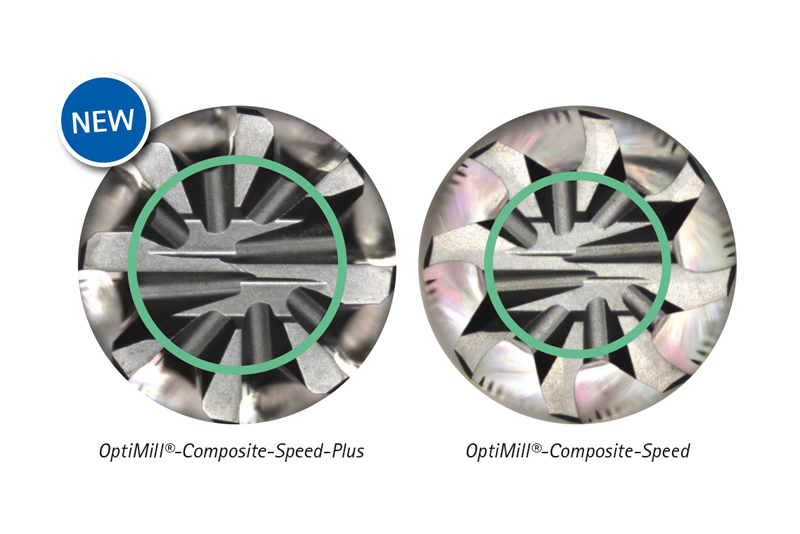

OptiMill-Composite-Speed-Plus

A new dimension of process reliability

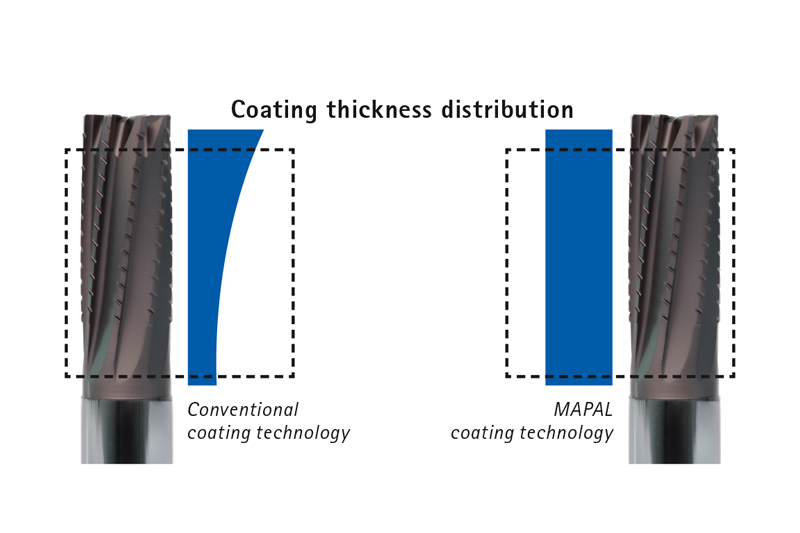

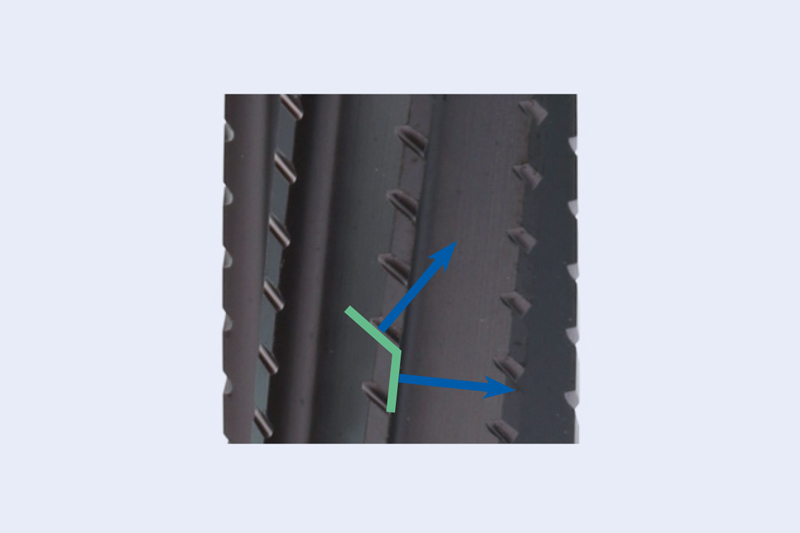

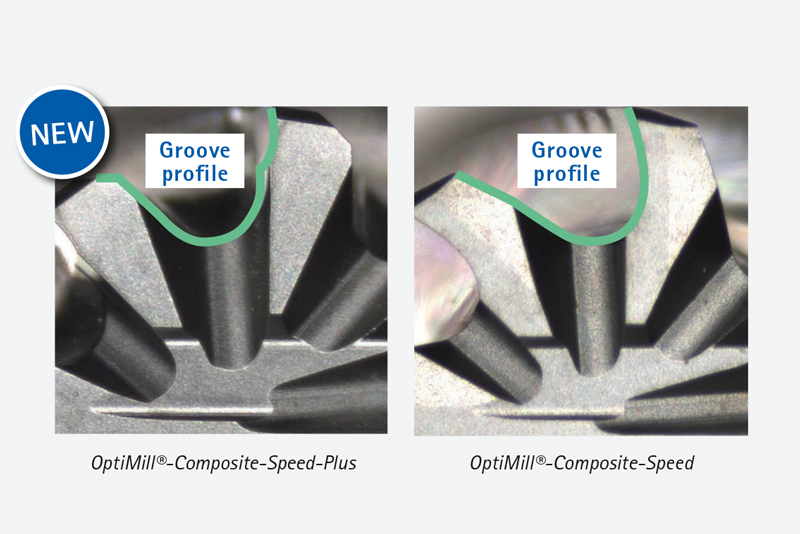

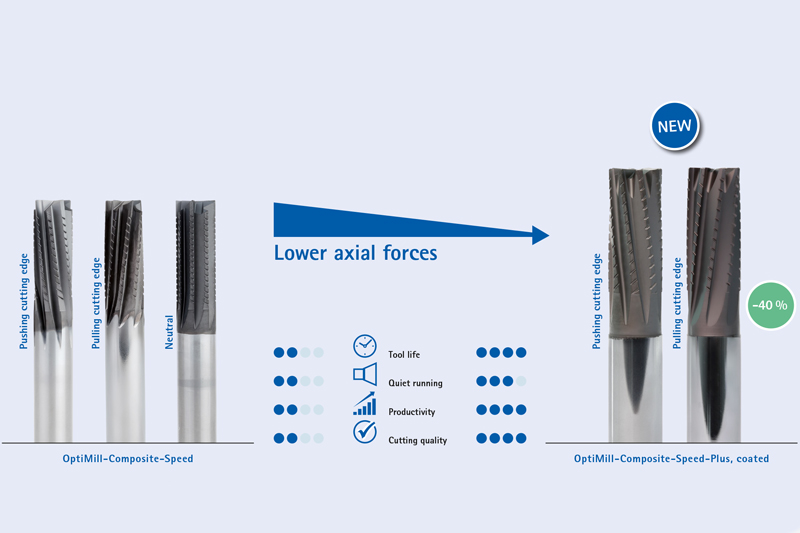

The OptiMill-Composite-Speed-Plus features a new diamond coating developed by MAPAL with even distribution and higher coating thickness. The bigger core diameter increases fracture strength by 50 percent. The improved groove profile ensures efficient, reliable removal of dust and process heat even when machining large volumes. The cutting wedge has been specially optimised to meet the requirements of brittle workpiece material. The special cuttingedge serration causes double compression so that fibre fraying on the workpiece edges of the upper and lower sides are reliably separated.

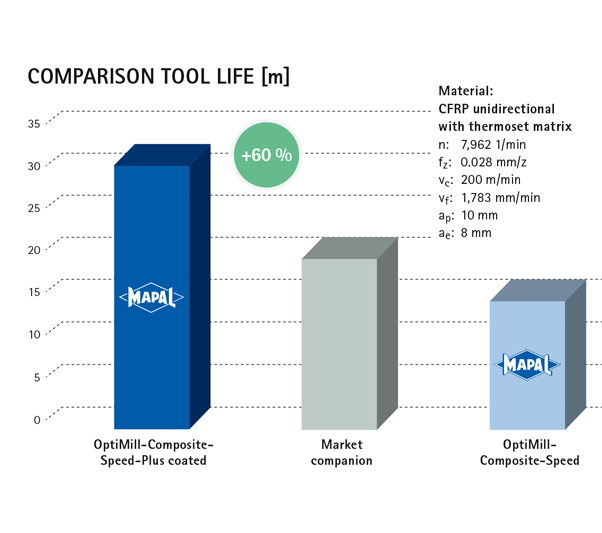

This allows the OptiMill-Composite-Speed-Plus to attain a new dimension in process reliability.Compared to the OptiMill-Composite-Speed, 20 percent longer tool life is achieved.

Customer Benefits

New tool design for more productivity

Variants at a glance

OptiMill-Composite-Speed-Plus

Shoulder milling cutter, coated

First choice in good process conditions

Stiff machining conditions

Good for high demands on productivity

Diameter range: 4.00-20.00mm

With pulling or pushing cutting edge

OptiMill-Composite-Speed-Plus

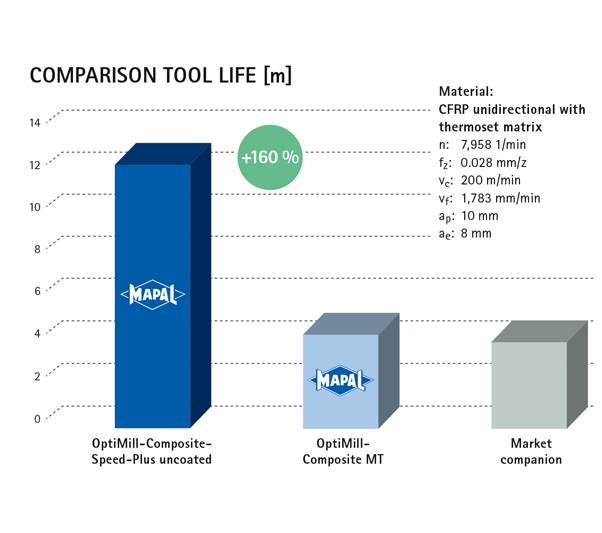

Shoulder milling cutter, uncoated

First choice for unfavorable process boundary conditions

Robust against vibrations

Good for low abrasiveness, e.g. B. GRP and natural FRP

Diameter range: 4.00-20.00mm

With pulling or pushing cutting edge