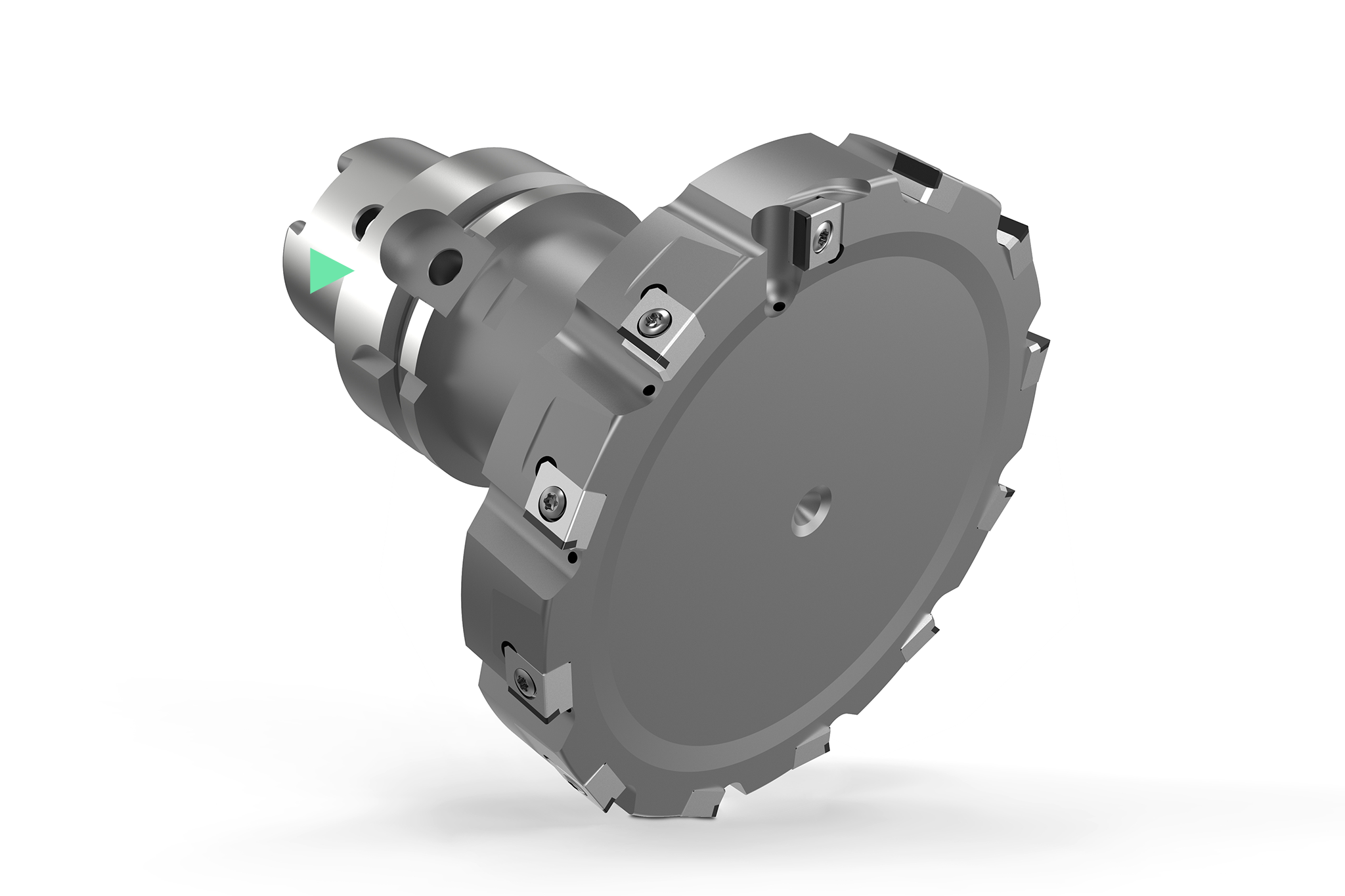

NeoMill-T-Finish

Finishing with maximum precision and without adjustment

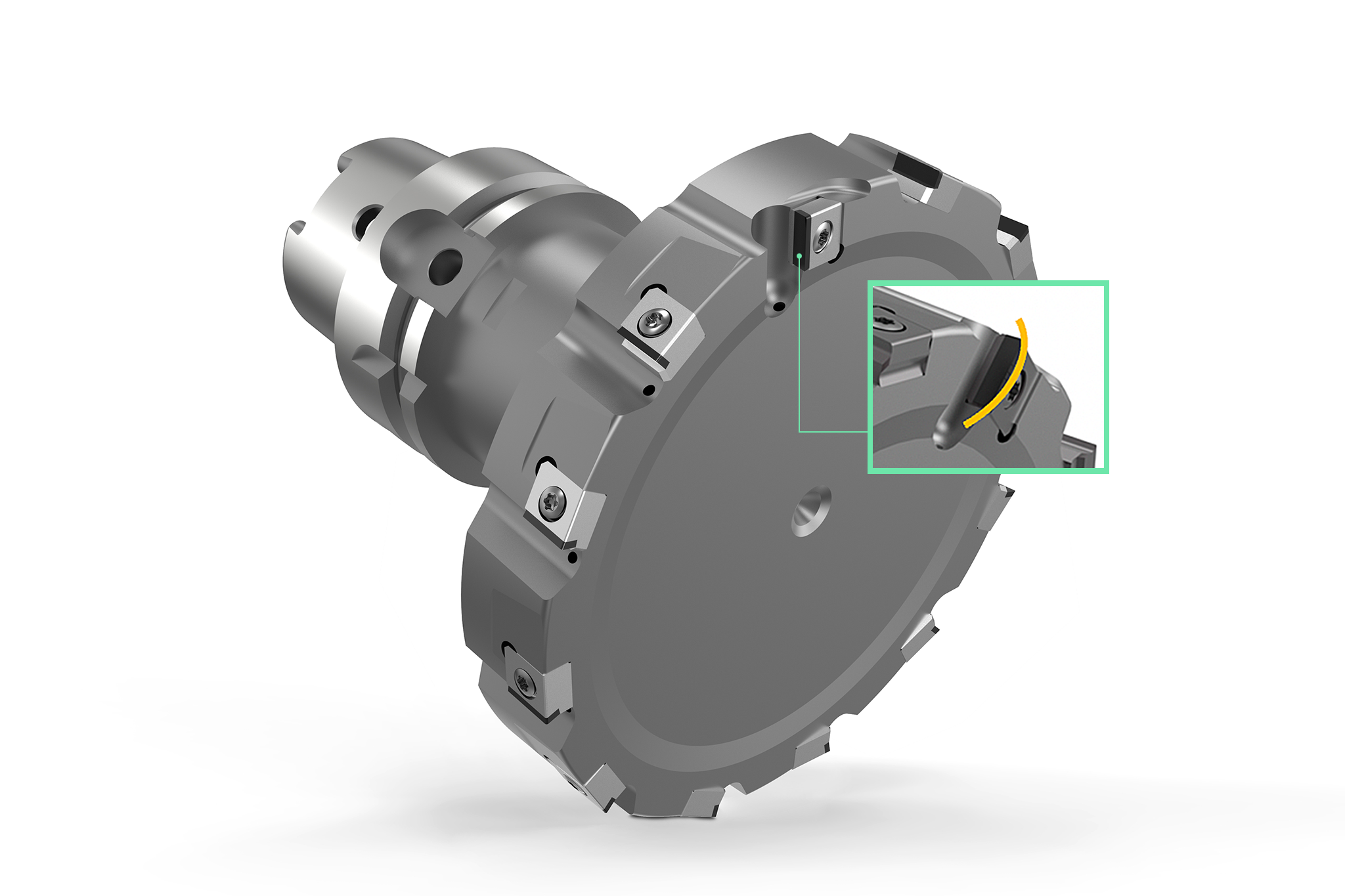

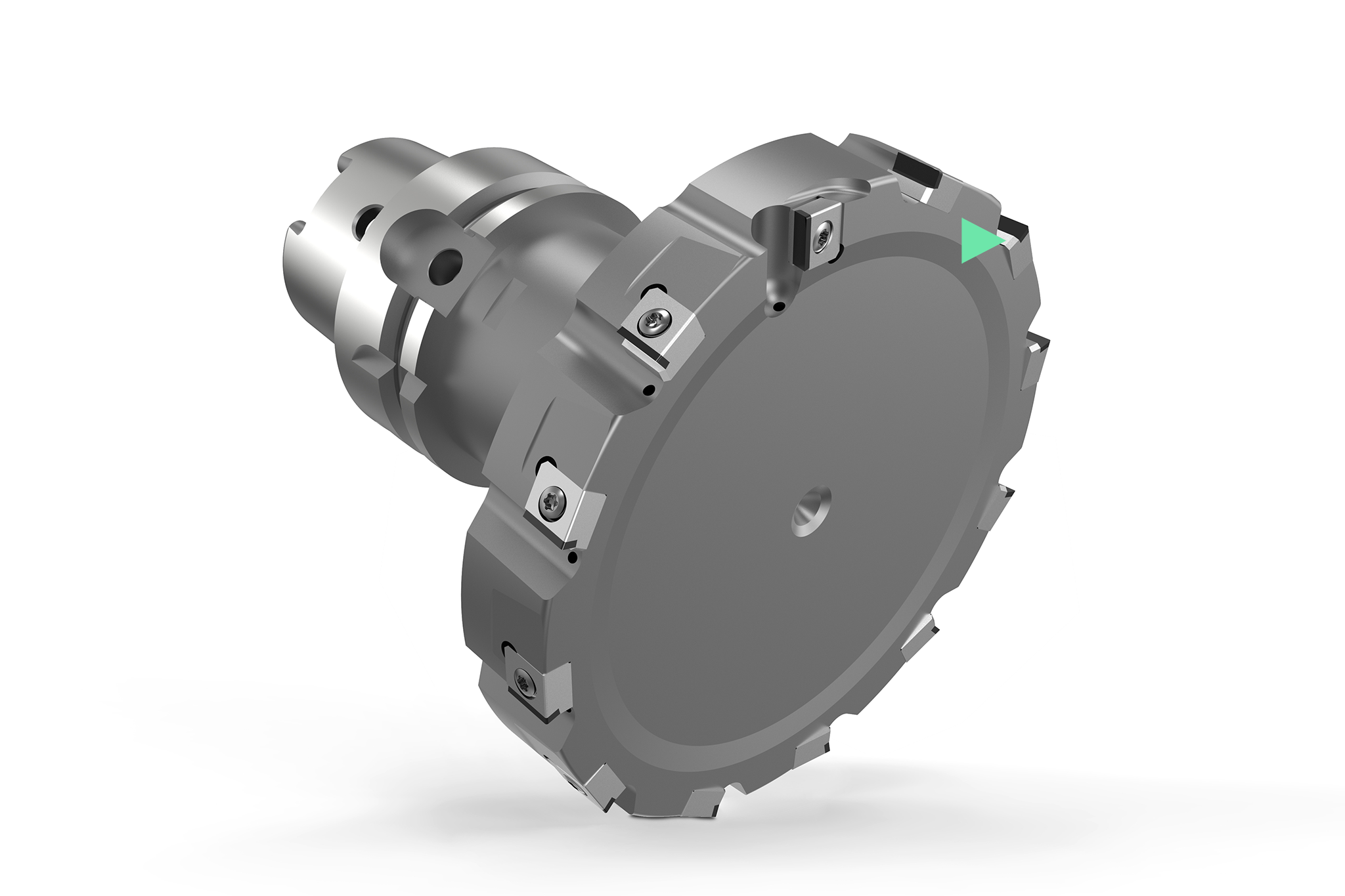

The NeoMill-T-Finish indexable insert milling cutter is designed for economical and reliable finish machining in series production. The milling cutter impresses with its very simple handling: The blades can be exchanged on site without confusion and do not need to be adjusted - MAPAL calls this principle Plug & Mill.

A high cutting material variance enables the NeoMill-T-Finish to be used for all aluminum alloys and also sand casting. The patent-pending blade arrangement ensures smooth running, low burr formation, uniform wear and therefore the best surfaces.

Configurable features

- Diameter range: 50,00-315,00 mm

- Cut surface: HSK, SK, CAT, BT

- Separation point: Milling arbor

- Number of tooth: Tool configuration and cutting data are defined for maximum efficiency and economy for each application

Plug & Mill principle

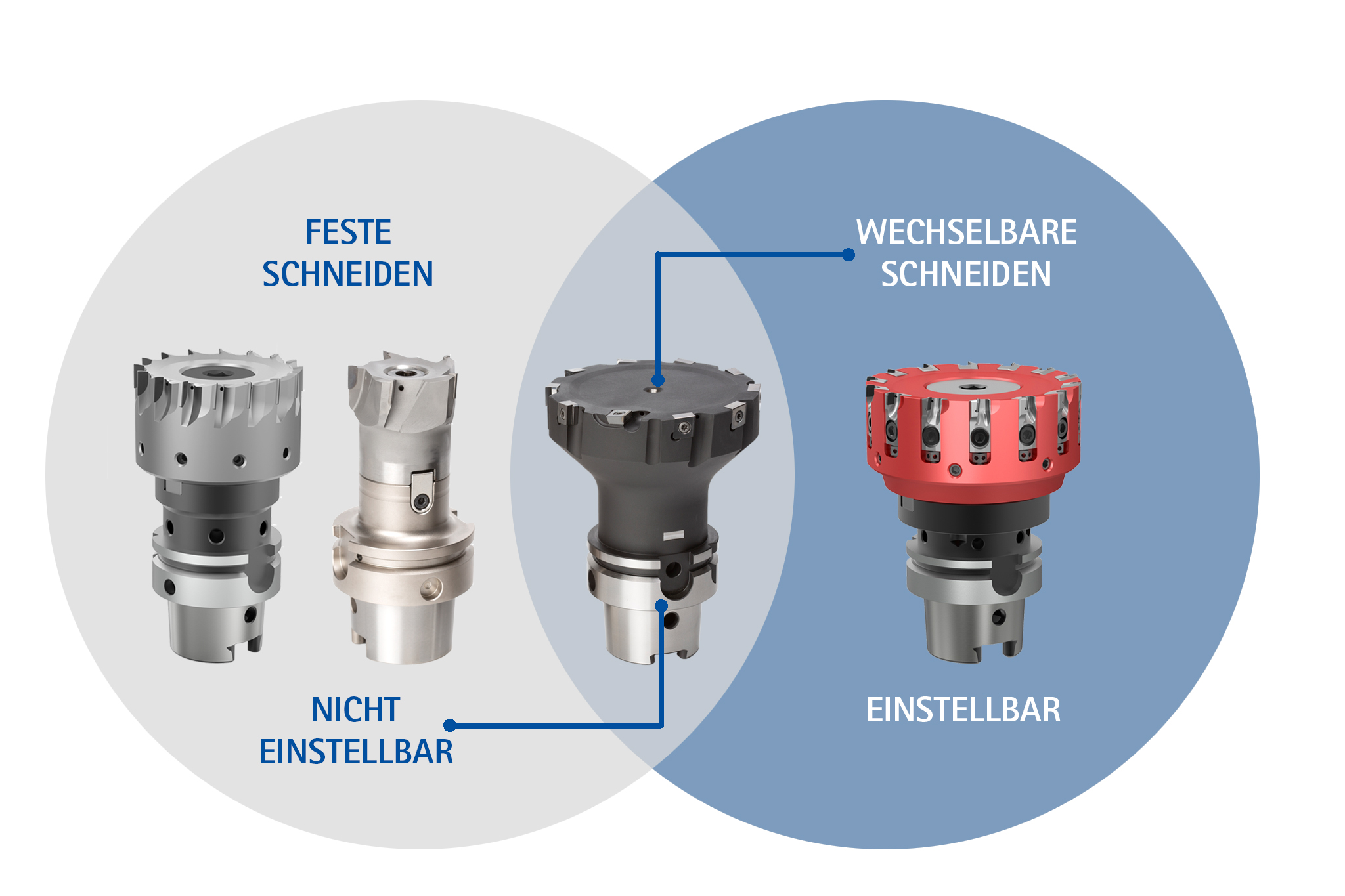

Scope of application

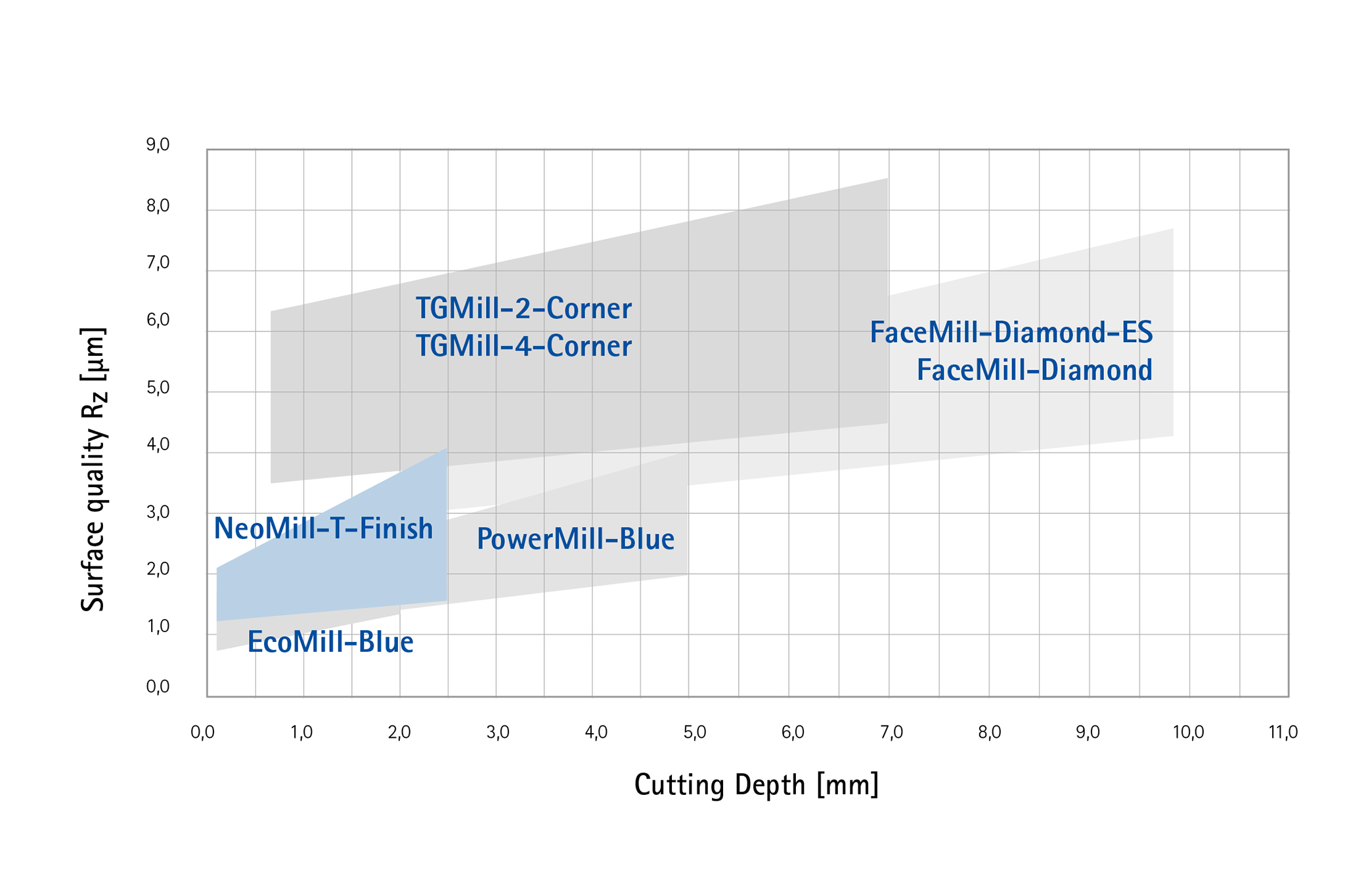

When selecting the optimum face milling cutter for aluminium machining, the surface finish to be achieved and the cutting depth play an essential role.