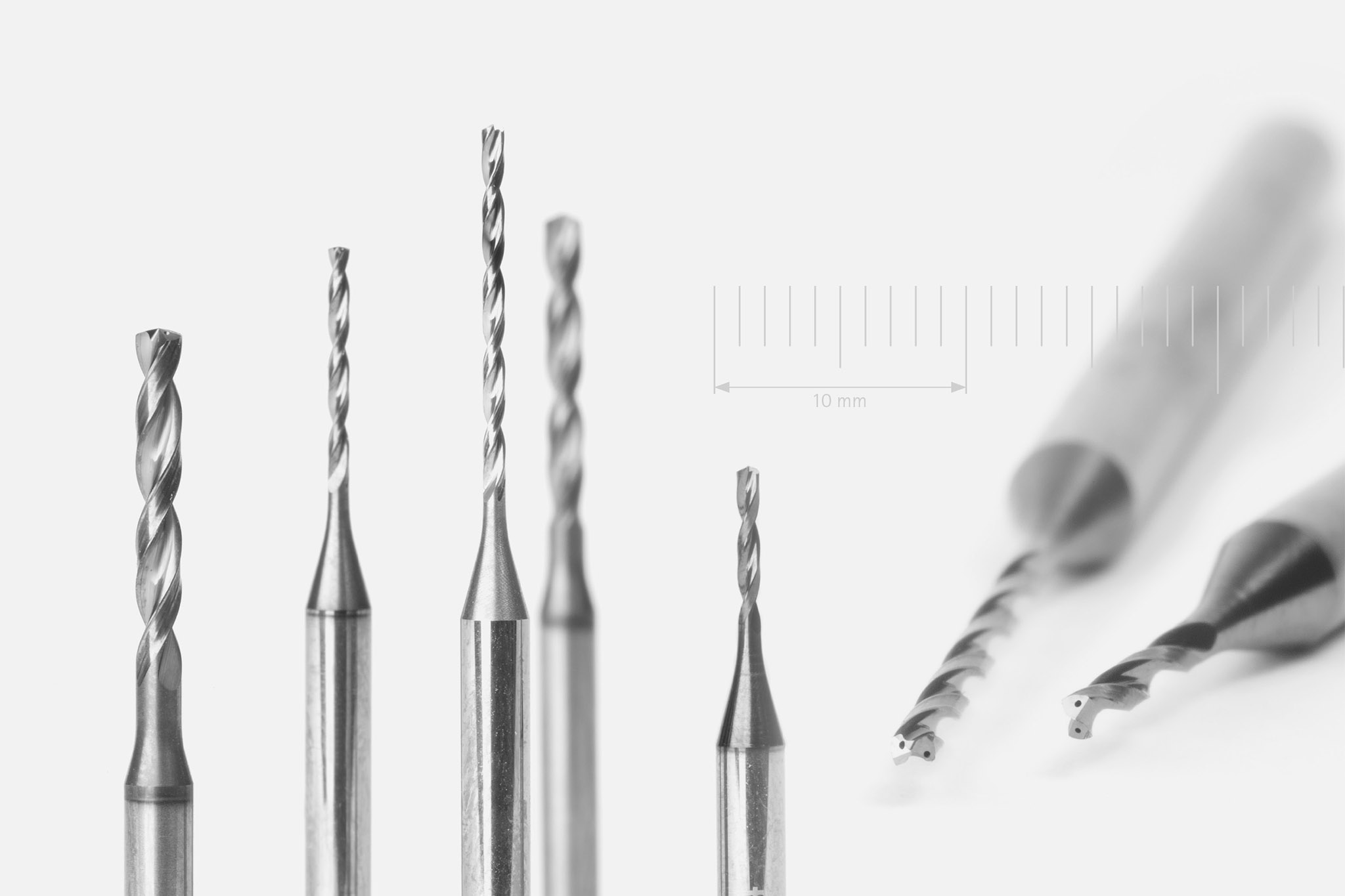

MICRO-Drill-Steel

Drilling diameters from one millimetre with internal cooling

Whether in the machining of injection nozzles for vehicles or in the production of moulds for the smallest injection moulding components – machining in the micro range is used in many applications.

MAPAL has expanded its range of solid carbide drills for steel machining in order to offer the right tool for these machining operations. The new MICRO-Drill series for the diameter range from 1.0 to 2.9 mm with internal cooling allows users to drill at depths of 5xD, 8xD and 12xD. Four guiding chamfers ensure the best guiding properties. The tool experts have developed the geometry especially for the efficient and economical machining of very small bores in steel.

The flute shape with core tapering ensures ideal chip removal even with tough steel materials. Maximum performance and tool life are guaranteed thanks to a new combination of cutting materials and specially adapted micro-geometries.

MAPAL has expanded its range of solid carbide drills for steel machining in order to offer the right tool for these machining operations. The new MICRO-Drill series for the diameter range from 1.0 to 2.9 mm with internal cooling allows users to drill at depths of 5xD, 8xD and 12xD. Four guiding chamfers ensure the best guiding properties. The tool experts have developed the geometry especially for the efficient and economical machining of very small bores in steel.

The flute shape with core tapering ensures ideal chip removal even with tough steel materials. Maximum performance and tool life are guaranteed thanks to a new combination of cutting materials and specially adapted micro-geometries.

Your direct contact

Contact person

Michael Villwock Global Head of Product and Application Management Solid Carbide Tools michael.villwock@mapal.com Phone: +49 8337 727-4815