Fraises à rainurer denture fixe

La gramme de fraises à rainurer performantes OptiMill de MAPAL garantit d’excellents résultats fiables, quelle que soit la tâche d’usinage. Rentabilité et qualité sont au centre des préoccupations des clients.

- Application concrète

- Avantages en termes de flexibilité

- Toujours le bon choix

Gamme de produits

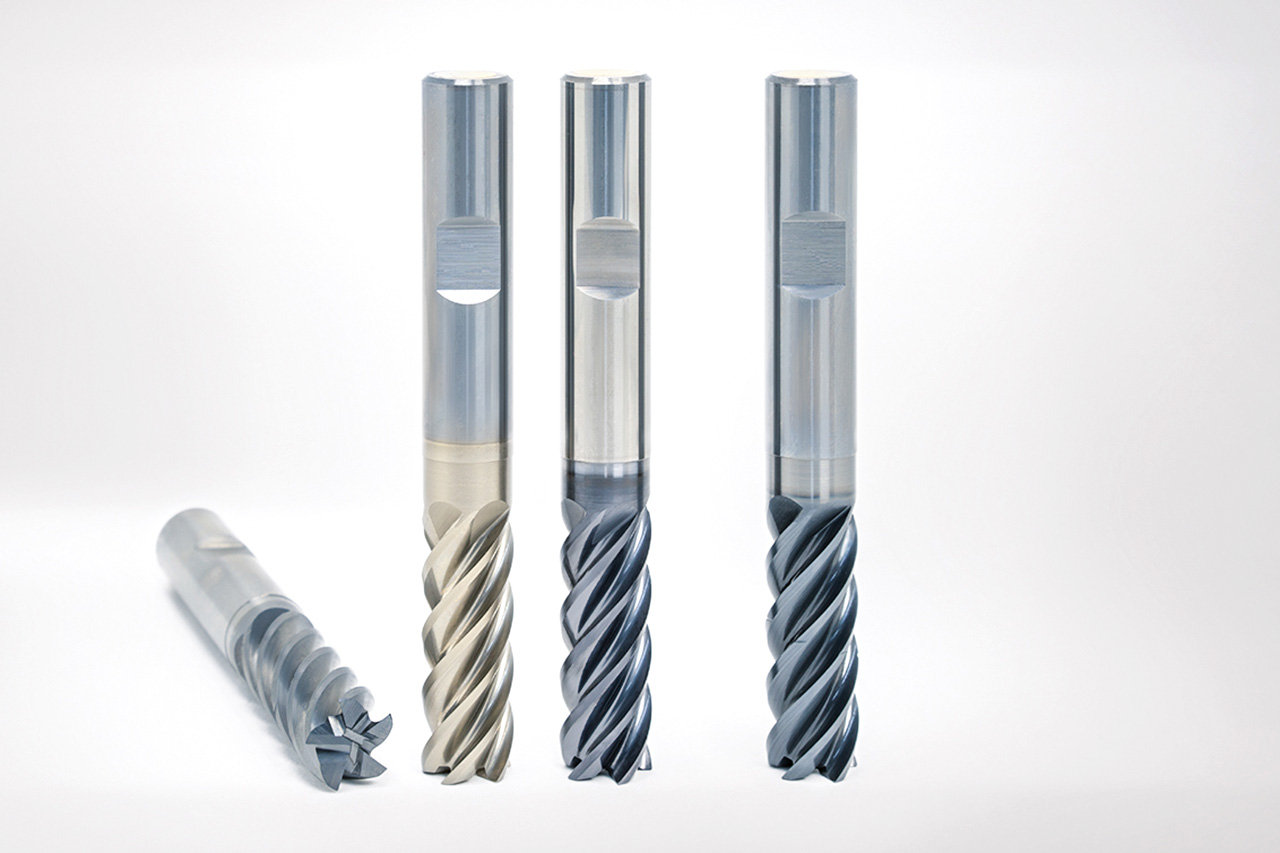

Rainurage et applications universelles

Fraises pour les applications universelles. Parfaitement adaptées au rainurage.

- Largeur de prise ae jusqu’à 1xD

- Plage de diamètres de 1 à 25 mm

- Modèles PCD jusqu’à 63 mm de diamètre

- Enlèvement de copeaux optimal

- Grand choix de longueurs et géométries pour toutes les applications

- Substrats haute performance et revêtements modernes pour d’excellentes durées de vie d’outil

Dressage – Ébauche

Pour obtenir un débit de copeaux maximal. Parfait pour le pré-usinage avec une grande surépaisseur.

- Grande avance (ae ~ 0,6xD)

- Plage de diamètres de 4 à 25 mm

- Nouveaux profils mortelés pour une répartition des efforts optimale sur l’arête de coupe

- Ébauche détalonnée

- Division angulaire inégale pour une coupe stable

Dressage – Finition

Parfait pour obtenir des surfaces de qualité exceptionnelle. Finition avec surépaisseur minime.

- Petite avance (ae ≤ 0,1xD)

- Plage de diamètres de 4 à 32 mm

- Nombre élevé de dents

- Répartition optimale des efforts de coupe

- Finition spéciale pour aciers trempés 50-65 HRC

Fraisage trochoïdal

Débit de copeaux maximal pour une excellente qualité de surface. Outil d’ébauche et de finition en un.

- Profondeurs de coupe allant jusqu’à 3xD

- Plage de diamètres de 4 à 25 mm

- Partie active extra longue

- Division angulaire inégale et partie active finement équilibrée pour ménager la broche machine et atteindre des durées de vie prolongées

- Enlèvement de copeaux optimal

- Utilisation avec un système CAM moderne

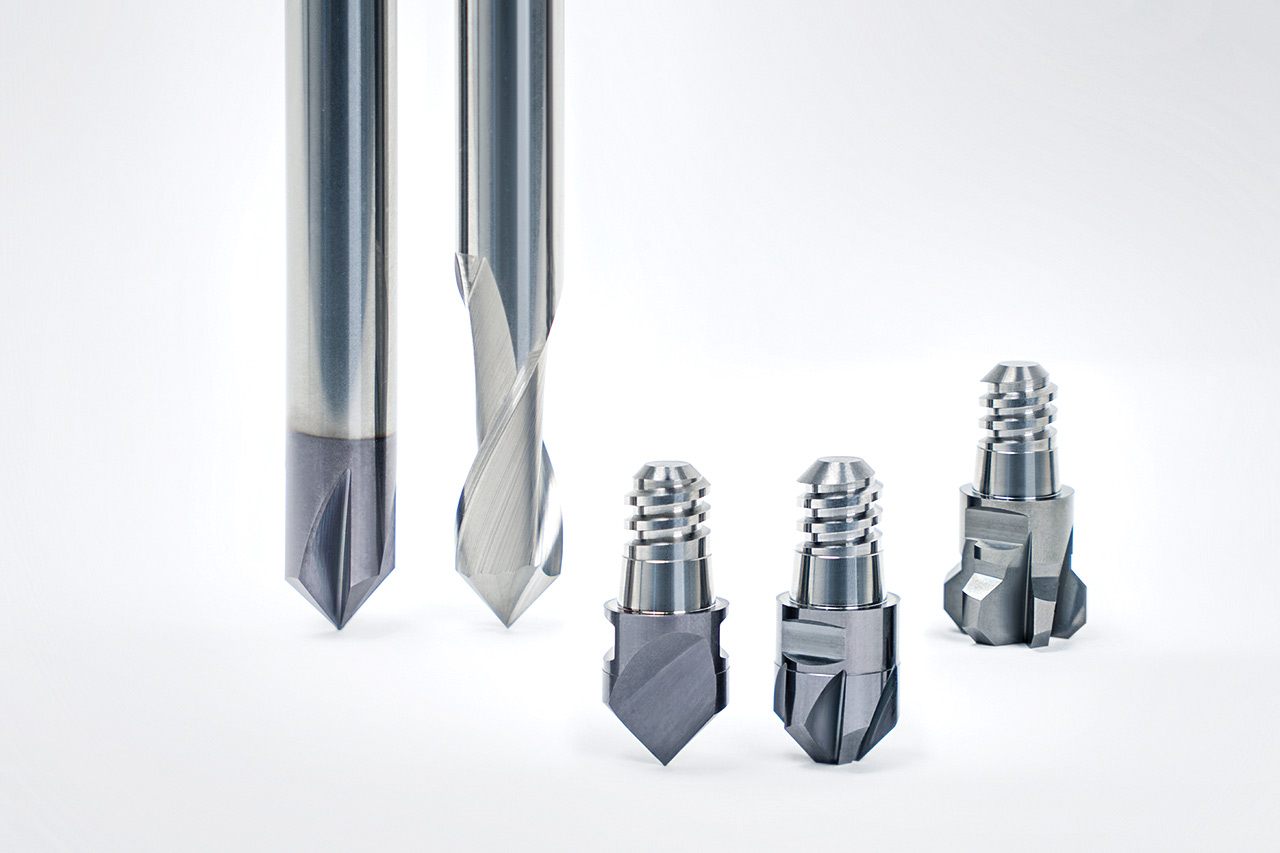

Fraisage à avances élevées

Spécialement pour fraisage à avances élevées et vitesses de coupe extrêmes.

- Faible profondeur de coupe (ap = 0,05xD)

- Plage de diamètres de 8 à 25 mm

- Avances maximales de 1,35 mm par dent pour 20 mm de diamètre.

- Plongée oblique et fraisage de poches même en cas de longs porte-à-faux

- Arrosage central pour dégagement copeaux optimal

Profile milling

Contour and copy milling with high shape accuracy.

- Low material removal rate (ap ~ 0.1xD, ae ~ 0.1xD)

- Diameter range from 1 to 25 mm

- Small diameter (from 1 mm) especially for milling tool steel and hardened steels from 50 to 65 HRC

- Highest precision for tool and mould building

- Close radius tolerances with full radius and toric end milling cutters

Chamfering, deburring and drill milling

Cost-effective chamfering and deburring of pre-machined parts.

- Diameter range from 3 to 20 mm

- Drill milling cutter for combination machining in one machining step, in particular for sheet metal and thin-walled parts

- Designs with replaceable head system for highest flexibility and cost-effectiveness

Custom tools to order

Customer-specific custom tools made of solid carbide for highest requirements.

- Realisation of complex geometries and contours for almost all applications

- High-performance coatings for every material

- Combination of several standard tools into one high-performance custom tool