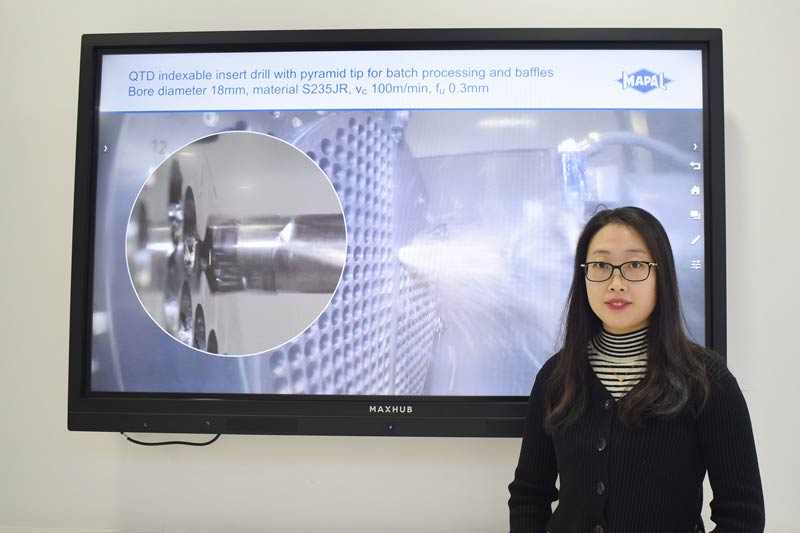

マパールに携わる人々 : Nancy Xue

上海にあるMAPAL Chinaのツールプロジェクトエンジニアであるナンシー・シュエは、男の職場と思われがちな場所で自分の道を切り開いています。

中国の拠点では、ツールの在庫、倉庫の最適化、ツール管理など、増大する需要に対応するためのインテリジェントなソリューションが求められています。プロジェクトエンジニアのナンシー・シュエはツールの製造を専門としています。彼女にインスピレーションを与えているのは、常に何かを改善したいという雇用主の意欲と特に対人関係です。

「私はツールレイアウトから価格の計算までを担当しています」とナンシー・シュエはMAPAL China Ltd.での活動の分野について説明します。

販売会社に加えて、マパールは中国市場の上海にPCDツール、ソリッドカーバイドツール、交換可能な切削インサートに特化した大規模な生産会社を維持しています。 戦略的に重要な都市にある19のオフィスでは、カスタマーサポート、販売、サービスに関して極めて早い応答が保証されます。

マパールは、新卒エンジニアである彼女の最初の職場で、2012年に入社してから営業や購買の経験を積んできました。現在はテクノロジー・エキスパート・チームのプロジェクト・エンジニアとして働いています。「私の立場は、主に急成長する中国市場の要求に応えることです。私はお客様のために、いかに完全なワークの加工を実現し、機械生産の精度を最適化するかに取り組んでいます。

注文の完了は道半ばに過ぎない

開発の自由

マパールグループ内では、さらなるトレーニングが決定的な要因となっています。技術、分野、部品ごとに定期的にトレーニングコースを開催し、実践的なノウハウを伝授しています。コンテンツは正確に開発され、通常、最新の知見や現在のお客様のニーズに基づいています。「さらにトレーニングを積まなければ行き詰ってしまいます。だから私はこのようなオファーがあるととてもやる気が出るんです。スキルを向上させて、キャリアアップするのを助けてくれますから」とナンシーは語ります。