13.10.2021

MAPAL Focuses on Fluid Technology

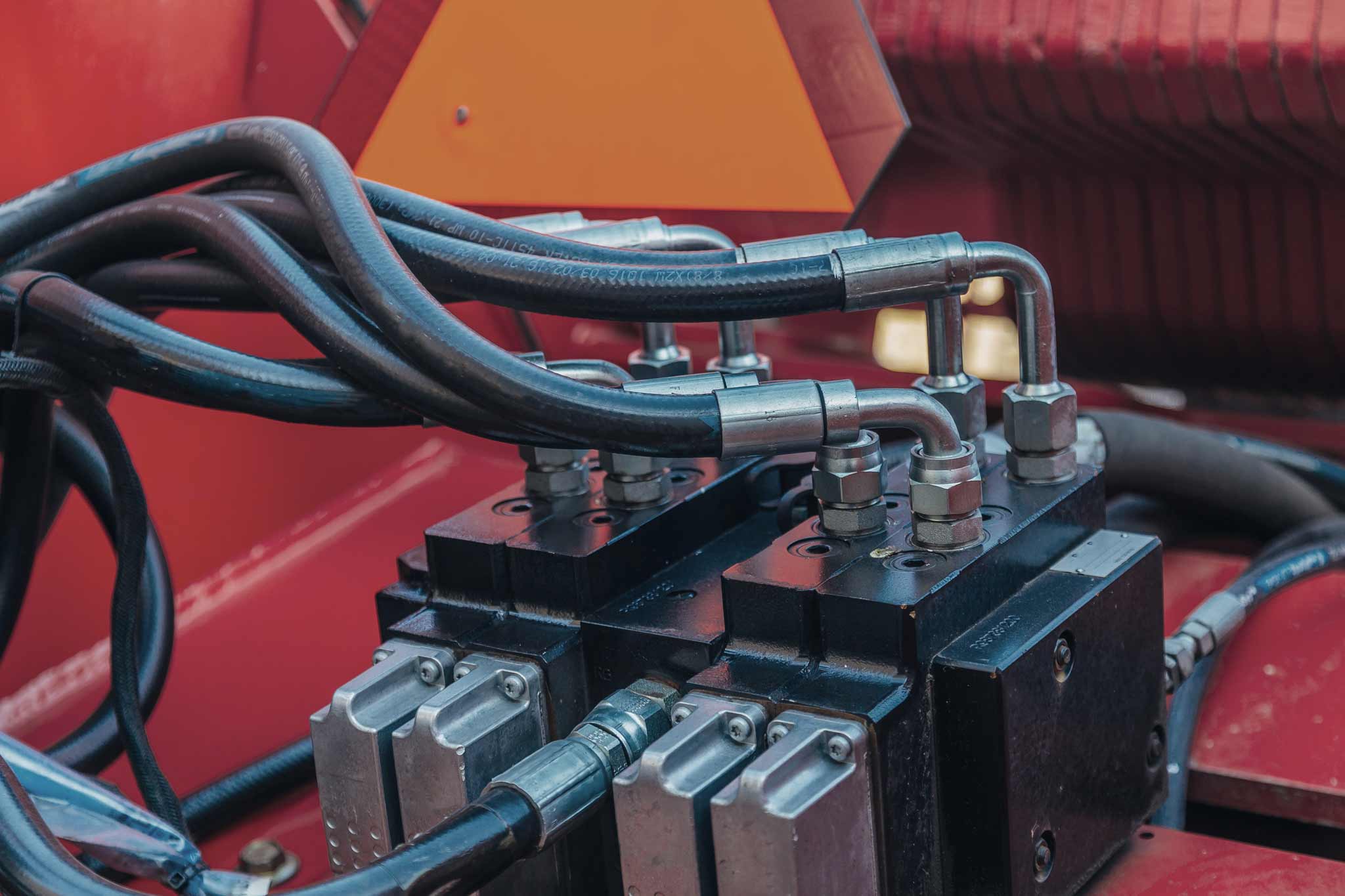

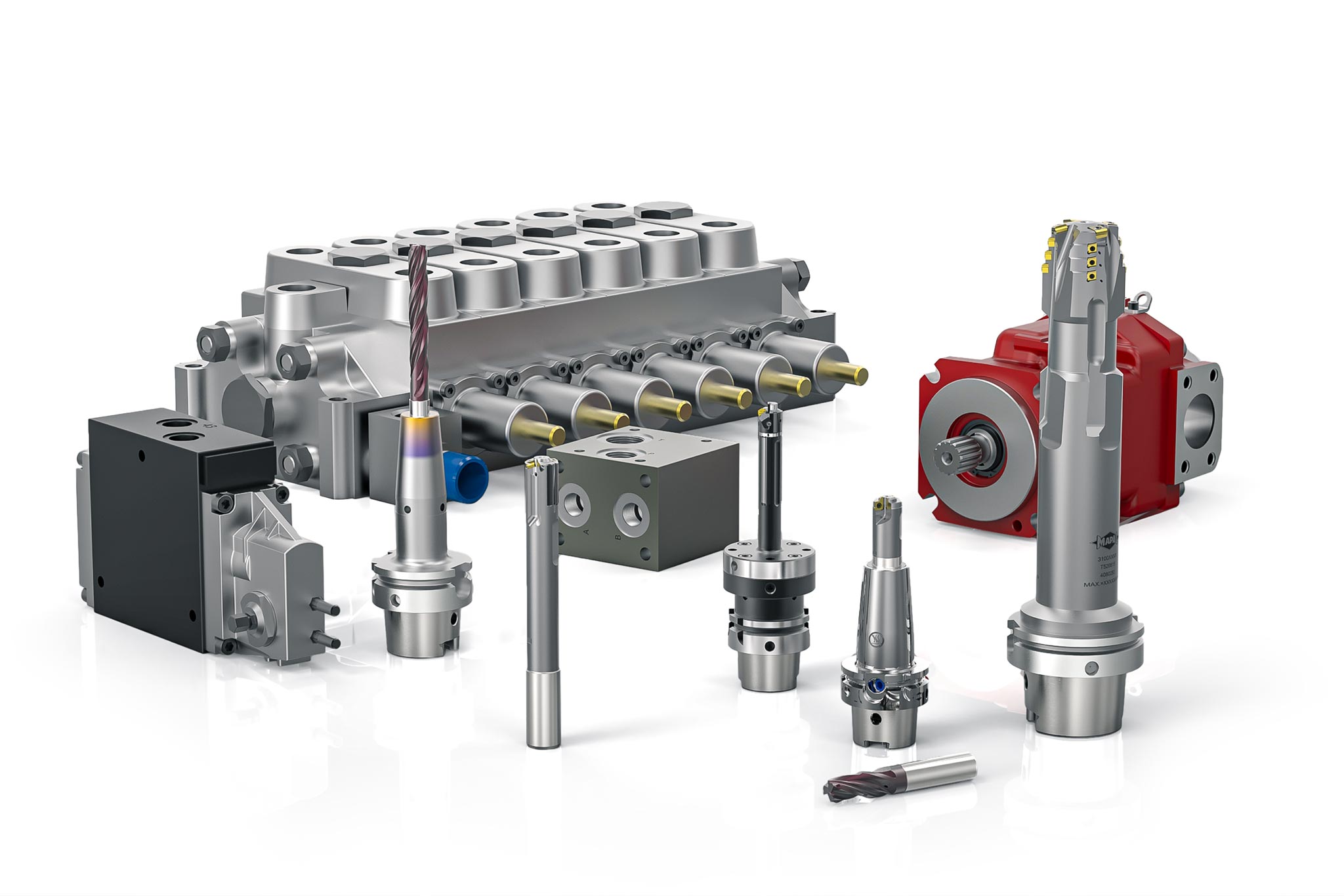

In addition to drive systems and components, fluid technology is one of the most important supplier sectors for all industrial production. Going forward, MAPAL will manage this important area as an independent market segment. For many years, customers have relied on the expertise of the tool manufacturer for demanding machining operations for hydraulic parts. However, as a solution provider, the tool manufacturer also has concepts for the cost-optimised manufacturing of the whole product.

Germany is the technology leader

The prospect of a comparatively crisis-proof growth industry is by no means the only reason for MAPAL to focus more on fluid technology. The workpiece materials to be machined (cast iron, steel, stainless steels and non-ferrous metals) are ideally suited to the tool manufacturer's product portfolio. Over and above carrying out demanding machining steps, MAPAL can support the entire process worldwide here as a technology partner. "The customers' needs fit our MAPAL DNA," is the analysis of Jochen Schmidt, who heads up the General Machining segment. To him, being a technology partner means understanding both the customers' needs and the actual product and how it functions in the end product.

Feinarbeit fürs Grobe

Alles hängt von der Hauptbohrung ab

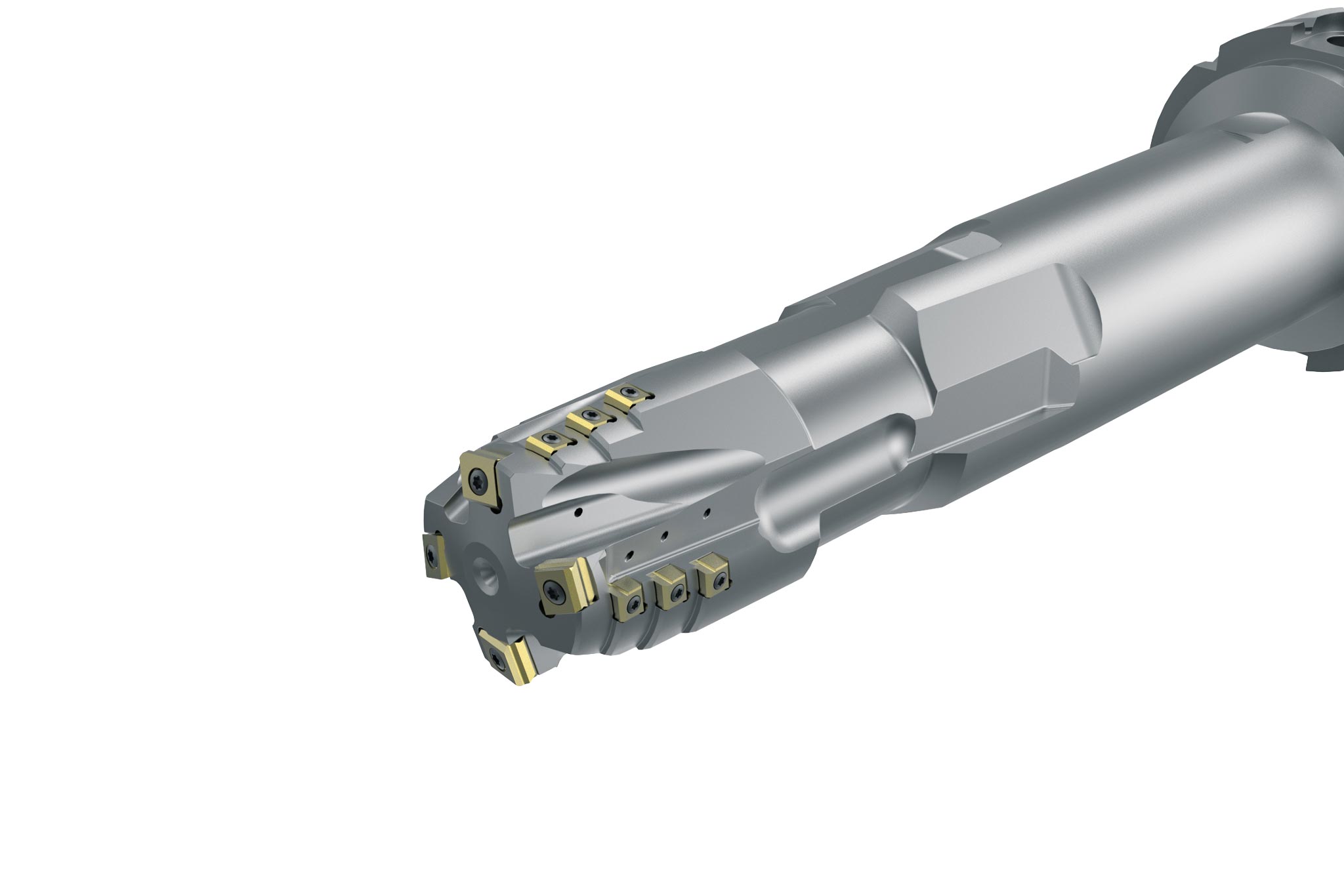

Der erste Bearbeitungsschritt trägt der unterschiedlichen Qualität der gegossenen Rohteile Rechnung. Weil die vorgegossenen Bohrungen relativ ungenau sind, ist zunächst eine präzise Pilotbohrung im ersten Steg zu erzeugen. Sie schafft die Voraussetzung dafür, dass in den weiteren Bearbeitungsschritten eine gute Zylinderform entsteht. Als nächstes durchfährt ein Vollhartmetallwerkzeug oder bei den größeren Bauteilen ein Werkzeug mit Wendeschneidplatten die gesamte Bohrung. Was der Pilotbohrer für den ersten Steg geschaffen hat, wird nun auf ganzer Länge hergestellt. Um in den Hohlkammern Ringbildung durch vorangetriebene Späne zu verhindern, sorgt MAPAL bei der Bearbeitung durch Verwendung der Tangentialtechnologie für einen weichen Schnitt. Das kann im Prozess einen separaten Waschgang einsparen.

Nach dieser Vorbearbeitung kommt das klassische Feinbohrwerkzeug von MAPAL zum Einsatz, das die Bohrung äußerst präzise fertig bearbeitet. Es verfügt über eine einstellbare Schneide und Führungsleisten, die verhindern, dass das Werkzeug von Steg zu Steg abgedrängt wird. So wird eine hohe Geradheit und genaue Zylinderform erzeugt.

Kostentreiber werden eliminiert

Immerhin kann die Bohrungsqualität mit dem MAPAL Feinbohrwerkzeug unter Umständen so weit verbessert werden, dass nur noch ein ein- oder zweistufiger Honprozess erforderlich ist oder das Honen sogar ganz entfallen kann. Wo noch drei Stufen gebraucht werden, geht dieser Prozess dank der guten Vorbearbeitung in vielen Fällen nennenswert schneller. Jeder Zeitgewinn zahlt sich hier aus. Die Hydraulikbranche ist zwar durch eine sehr hohe Bauteilevarianz gekennzeichnet, doch gehen die Stückzahlen in der Serienfertigung in die Millionen.

MAPAL ist es wichtig, mögliche Kostentreiber ausfindig zu machen und zu eliminieren. „Als Technologiepartner haben wir das Produktportfolio, um den gesamten Prozess für das komplette Bauteil anforderungsgerecht auslegen zu können“, versichert Jochen Schmidt. Neben der zentralen Spool-Bohrung übernimmt MAPAL auch die Feinbearbeitung bei der so genannten Druckwaagenbohrung und konnte hier das Honen komplett ersetzen. Mit 2 µ bei Geradheit und Rundheit ist auch bei dieser kürzeren Bohrung hohe Genauigkeit verlangt.

Hohe Effizienz mit Standardwerkzeugen

Die Bauteile sind 500x500 mm große Ventilblöcke aus GGG50, bei denen drei Kolbenbohrungen von beiden Seiten zu bearbeiten sind, wobei das Aufmaß im Durchmesser bis zu 16 mm geht. Die TSW von Mapal erzeugen kurze Reißspäne und verhindern damit, dass Ringe in die Zwischenräume gedrückt werden, die dann mit hohem Aufwand entfernt werden müssen. Pro Bauteil konnte die Eingriffszeit um 15,33 Minuten verkürzt werden. Die Gehäuse des entsprechenden Typs wurden in einer Stückzahl von 500 gefertigt, was insgesamt eine Zeiteinsparung von 128 Stunden bedeutet.

In Zukunft die kompletten Bauteile zu zerspanen, ist für MAPAL ein strategischer Schritt. Gab es früher in der Industrie noch den Zielkonflikt zwischen hoher Produktivität oder möglichst guter Qualität, lässt sich heute beides miteinander prozesssicher vereinbaren.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342