17.01.2020

With additive manufacturing to more productivity - Bell tool for external machining from MAPAL

Thanks to lower weight to significantly higher cutting data

New bell tool with low weight, long tool life and best cutting data

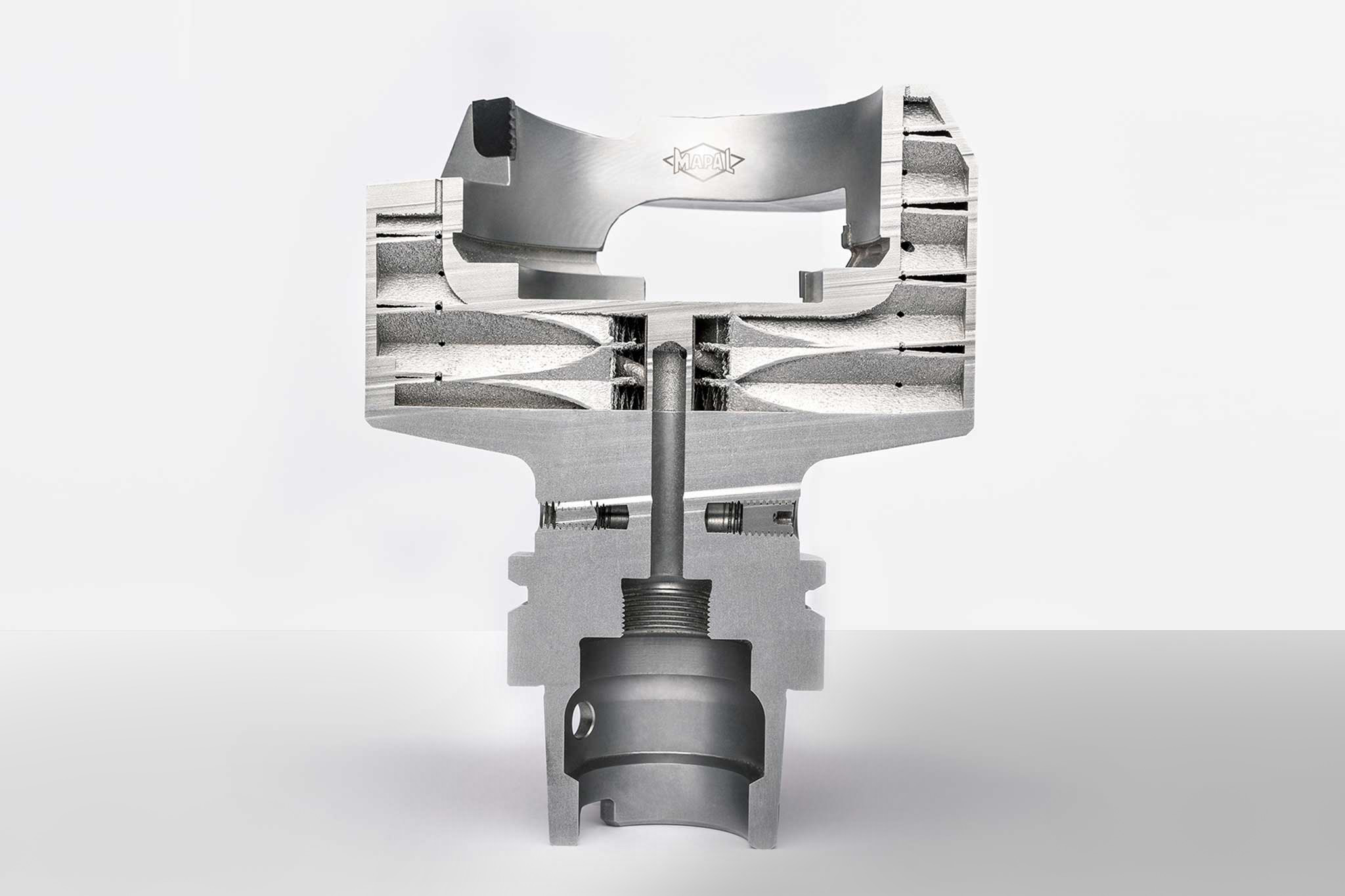

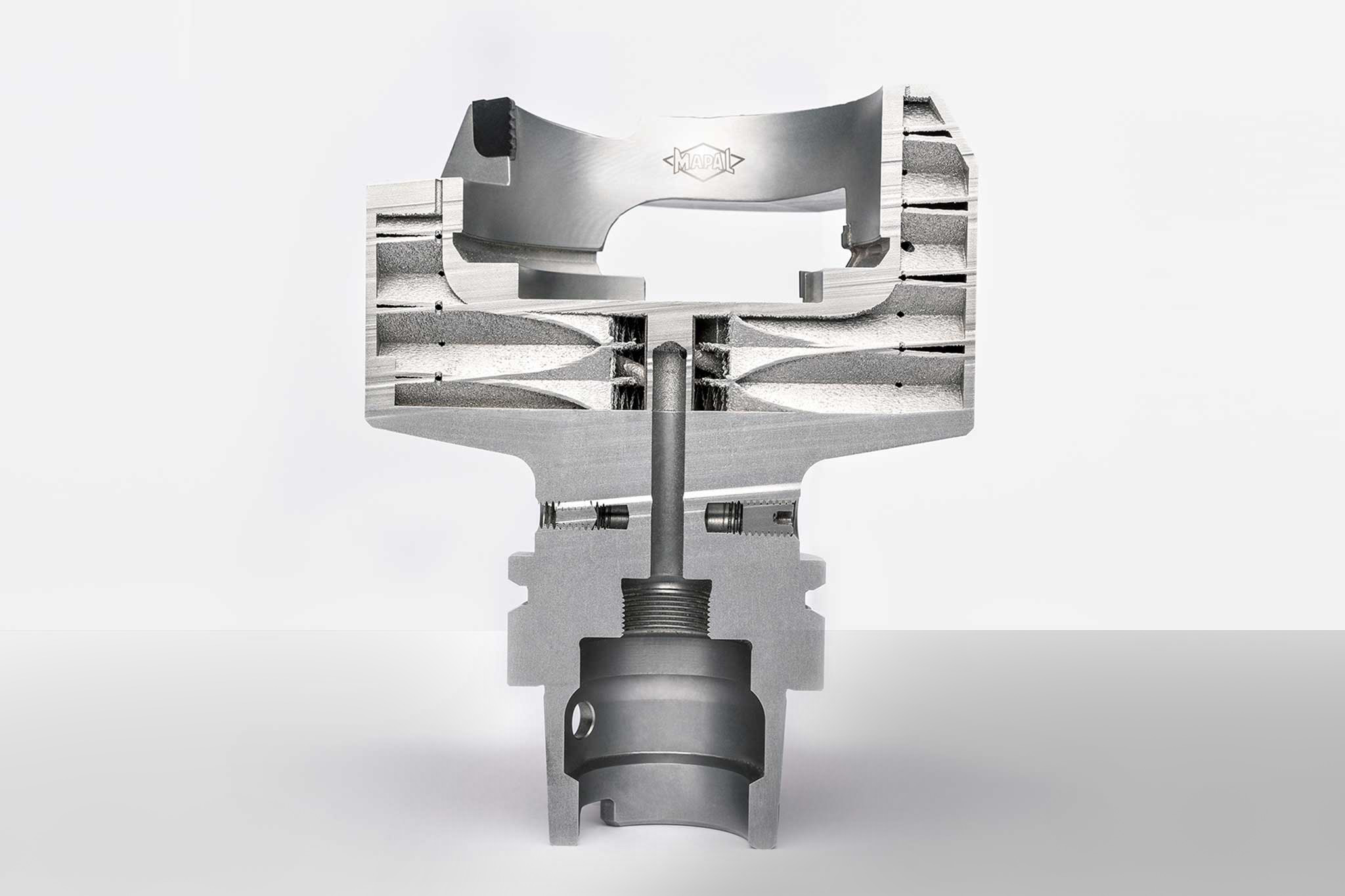

An example of how MAPAL uses this advantage of 3D printing in practice is the new bell tools with brazed PCD inserts. Bell tools are used for the external machining of hose connections, among other applications. These connections, for example on turbochargers, must satisfy complex contour requirements. Manufacturing must be correspondingly precise. Existing processes are also subject to continuous improvement so that manufacturing is cost-effective and reliable in series production.

MAPAL has therefore optimised the existing, conventionally manufactured bell tool. Using the selective laser melting process, the inside of the tool has been modified – instead of solid material there is now a specially designed honeycomb structure. As a consequence, the tool is 30 percent lighter and the tool life is increased by approx. 40 percent due to the damping effect. It is therefore possible to machine faster; the machining quality remains at the same high level. In total the machining time has been reduced by 50 percent.