Compressor Scroll

Parafuso Scroll de EN AW-4032 (AlSi12,5) & EN-GJS-400-15

Situação inicial no cliente

- Frequentes reclamações de clientes finais devido à qualidade inconstante dos componentes na usinagem em peças com paredes finas

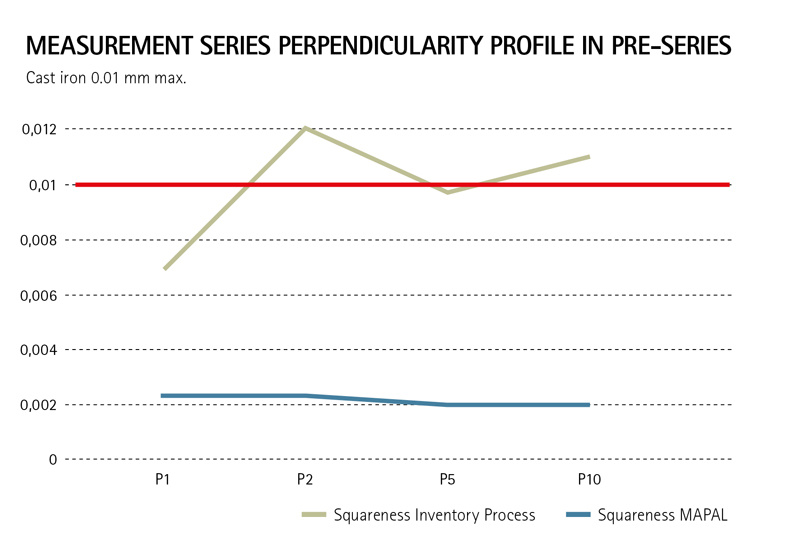

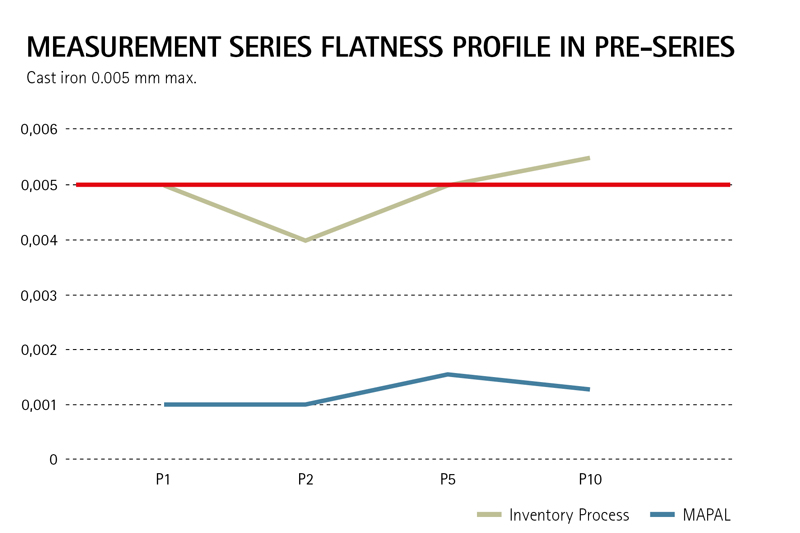

- Status da pré-série dos componentes scroll de ferro fundido

解决方案的特性

- Frequentes reclamações de clientes finais devido à qualidade inconstante dos componentes na usinagem em peças com paredes finas

- Status da pré-série dos componentes scroll de ferro fundido

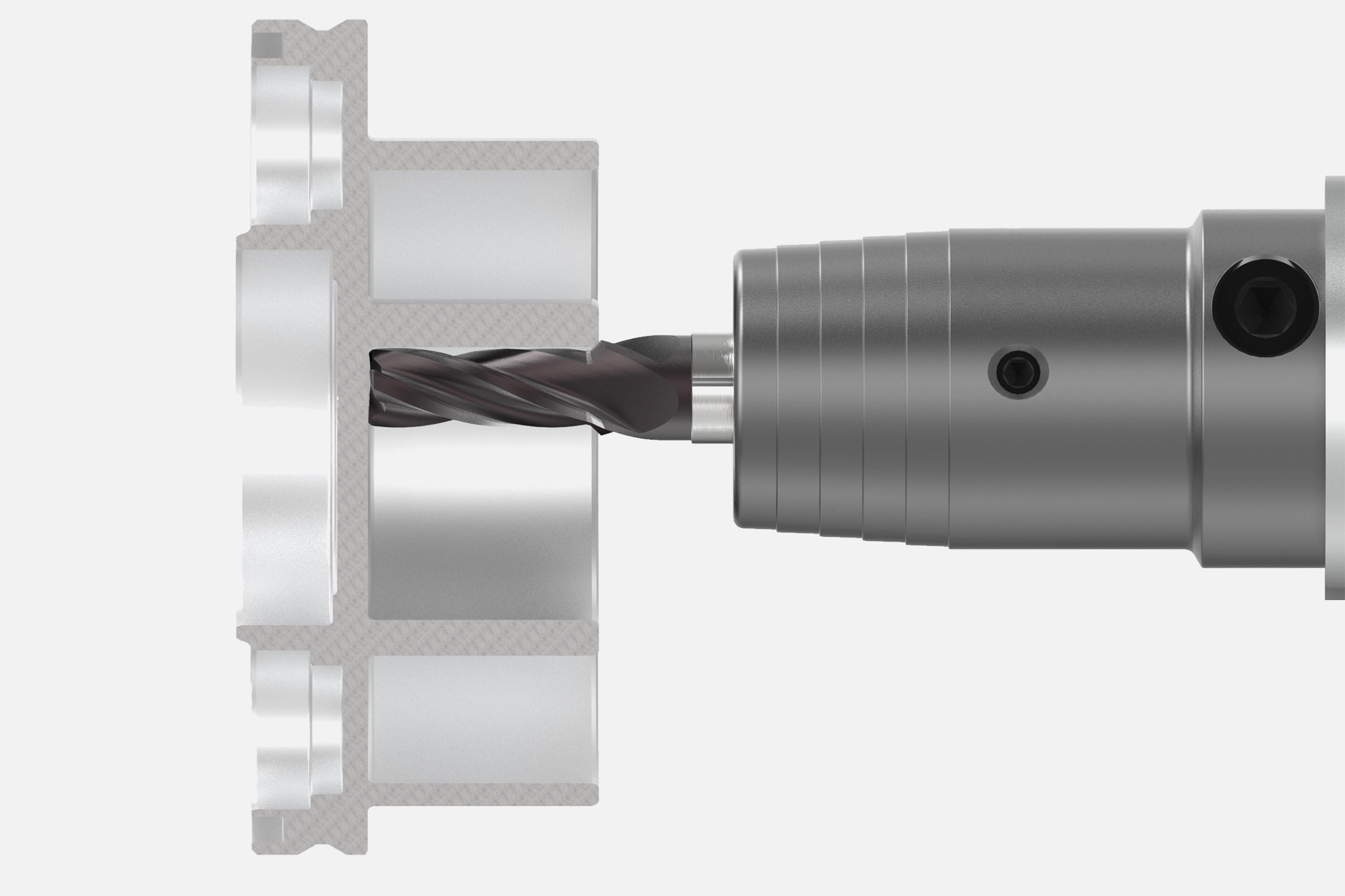

Scroll de alumínio

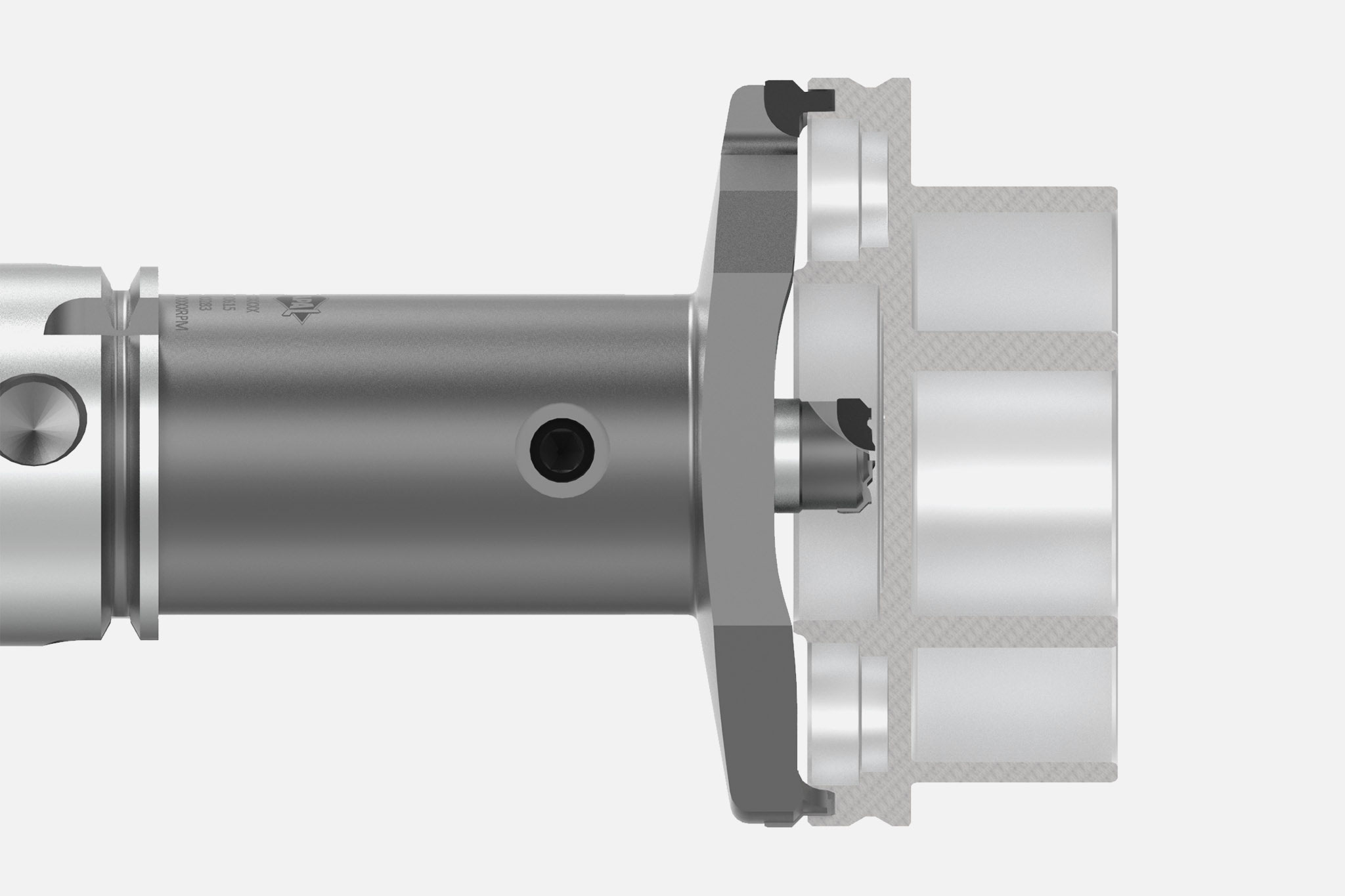

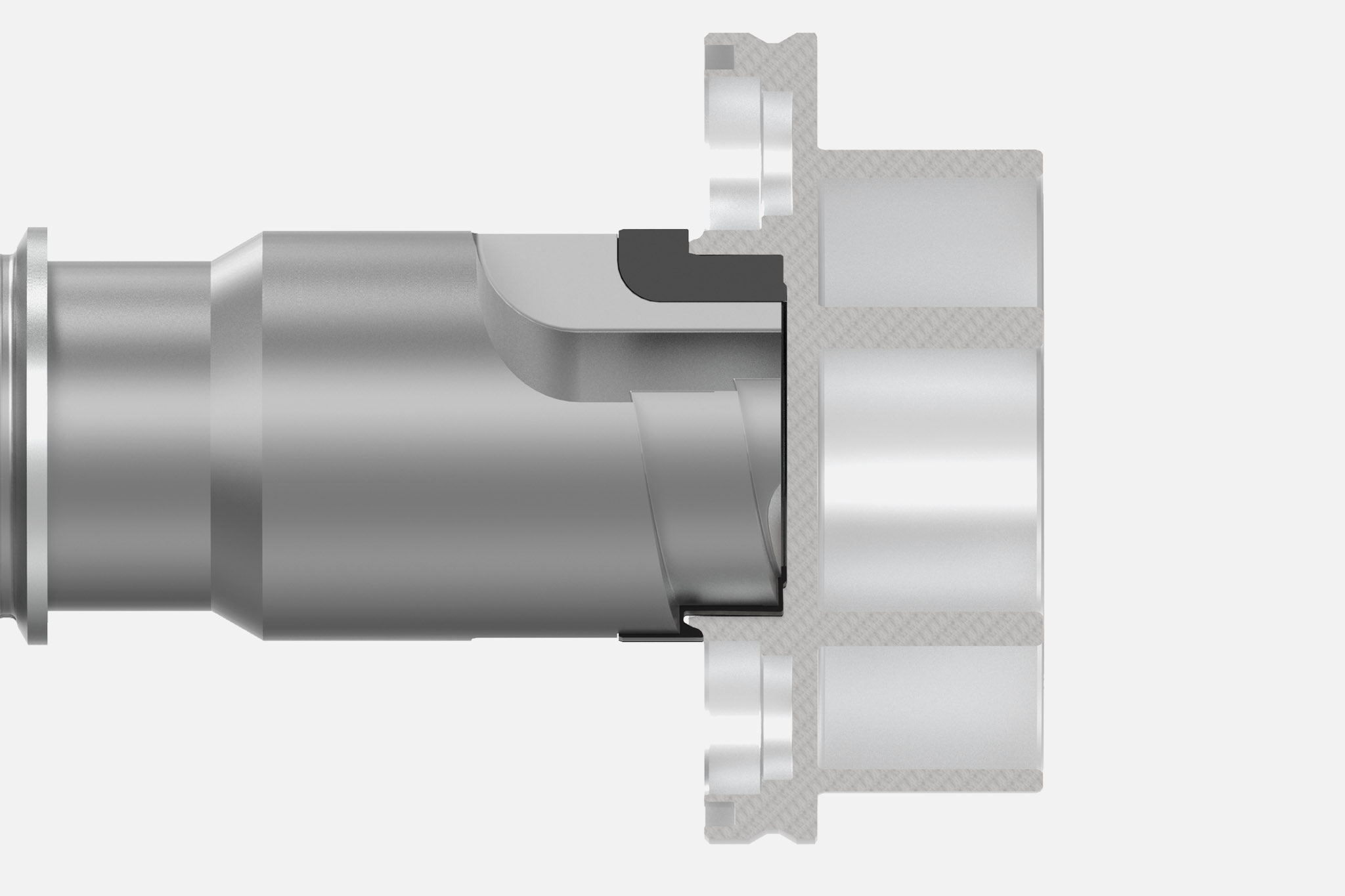

鋳鉄製スクロール

スクロールコンプレッサーの加工ステップ

Vantaggi

- La qualità costante dei componenti evita reclami da parte dei clienti finali e riduce significativamente i costi

- Evidenti vantaggi competitivi grazie alla collaborazione con MAPAL e alla pluriennale esperienza nel settore automotive

- Lavorazione completa e affidabile in alluminio e ghisa grazie all’assistenza intensiva nella produzione di grandi serie