04.12.2023

Aluminiumzerspanung in neuen Dimensionen

Hochvolumenfräser von MAPAL bei bavius

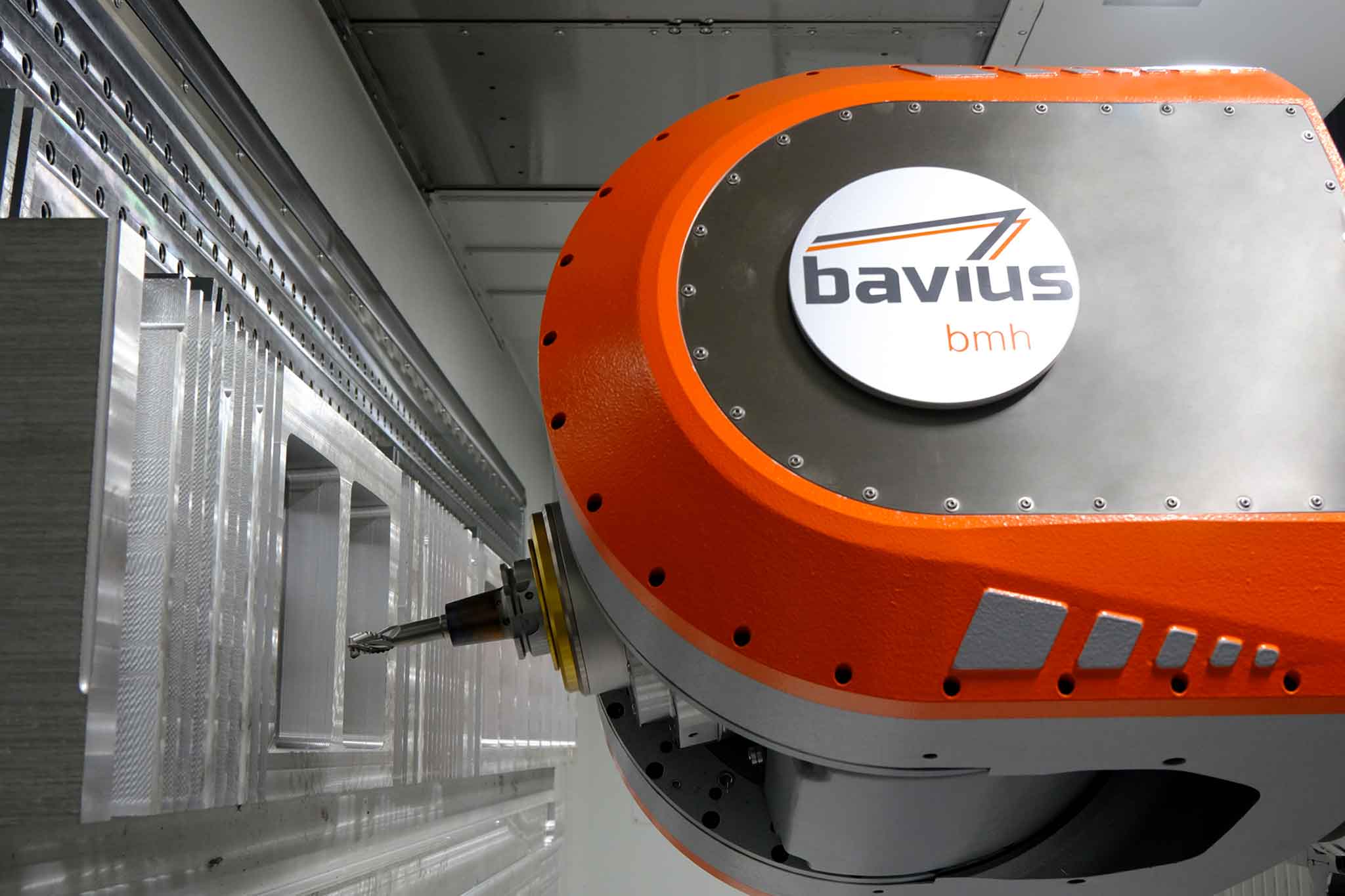

Auf seinem neuen High-End-Modell HBZ AeroCell 160 konnte der Werkzeugmaschinenhersteller bavius mit einer neuen Generation von Aluminium-Hochvolumenfräsern des Werkzeugherstellers MAPAL beeindruckende Zeitspanvolumen von über 20 Litern pro Minute erreichen. Das Ergebnis dieser erfolgreichen Zusammenarbeit kommt für die Flugzeugindustrie zur rechten Zeit: Sie startet nach der Corona-Delle wieder voll durch.

Trend geht zu horizontaler Bearbeitung

Bei den Maschinenkonzepten vollzieht die Flugzeugindustrie gerade einen Wandel. Nachdem jahrzehntelang vorzugsweise auf Gantry-Maschinen oder vertikalen Bearbeitungszentren gearbeitet wurde, werden jetzt bei Neuinvestitionen horizontale Maschinen bevorzugt, bei denen die Bauteile hochkant aufgespannt sind und die Spindel horizontal herangeführt wird. Für den horizontalen Aufbau spricht vor allem die leichtere Abfuhr der großen Menge an Spänen, die hier praktisch von selbst in den Späneförderer fallen.

Bei bavius merkt man deutlich, dass die Luftfahrtbranche die Coronakrise bald überwunden hat. Die Passagierzahlen haben bereits wieder das Niveau vor der Pandemie erreicht und steigen weiter. Entsprechend werden auch wieder neue Flugzeuge gebraucht, was Maschinenherstellern die Auftragsbücher füllt. Die Nachfrage aus Deutschland, Frankreich, Spanien und weiteren Ländern zeigt, dass auch in Europa wieder viel investiert wird. Gefragt sind vor allem dynamische Maschinen mit hohen Spindelleistungen.

Bis ans Limit und weiter

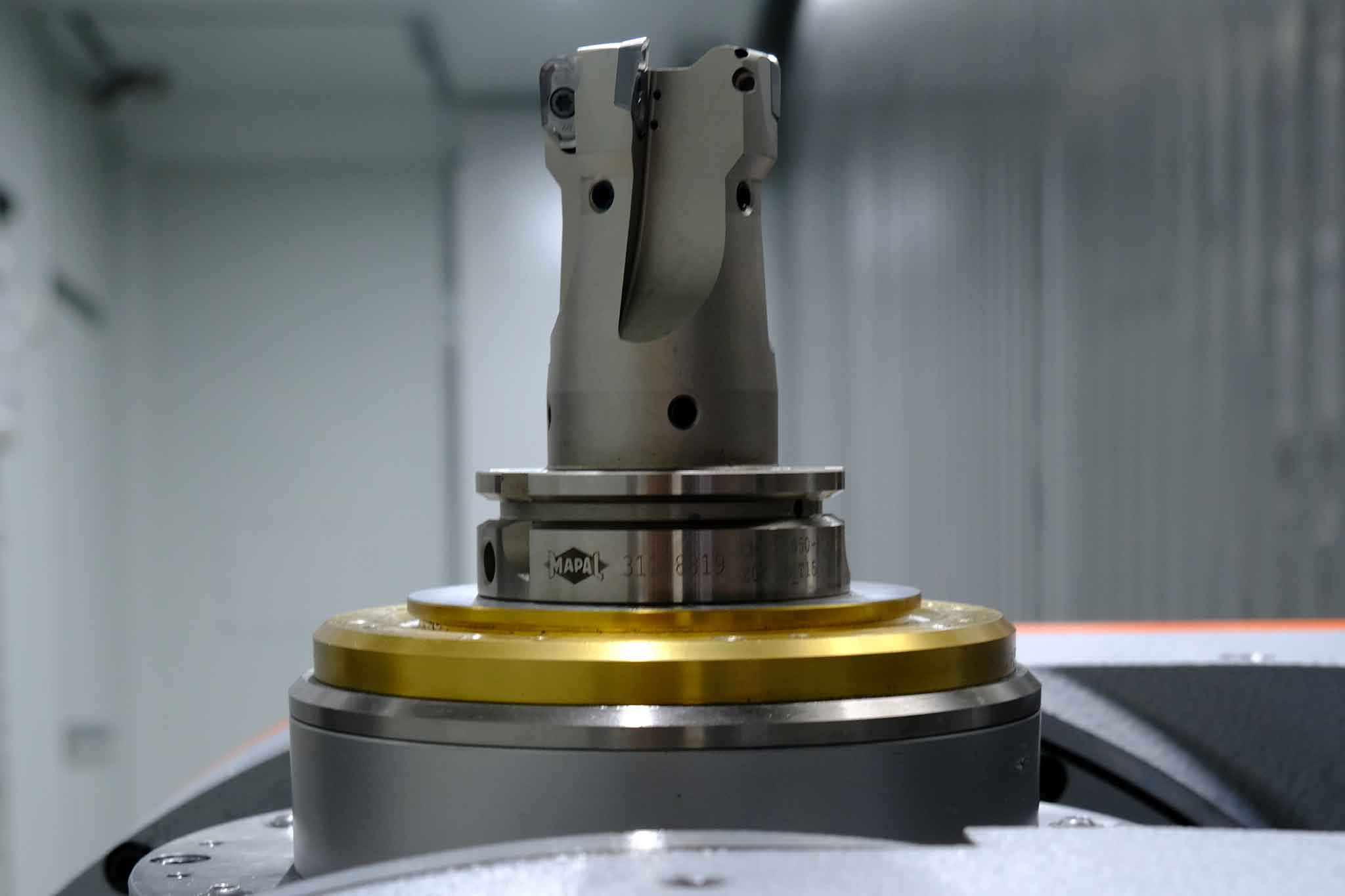

Weil Fräser der OptiMill-SPM-Reihe zuvor schon bei bavius im Einsatz waren und dabei sehr gut performten, wurde MAPAL erneut angefragt. Das Timing passte: Mit dem OptiMill-Alu-Wave hatte der Werkzeughersteller gerade eine Weiterentwicklung seines VHM-Schruppfräsers fertig entwickelt und bot zudem für größere Durchmesser den neuen Alu-Hochvolumenfräser NeoMill-Alu-QBig mit Wendeschneidplatten.

Die Fräsversuche sind im Aufbau einfach gehalten, stellen jedoch an die Werkzeuge höchste Anforderungen. bavius fräst dazu eine Reihe von Vollnuten in eine große Aluminiumplatte. Stefan Diem verfolgt damit einen sehr pragmatischen Ansatz: „Wenn das Werkzeug die Vollnut schafft, können wir damit auch Taschen fräsen und jede andere Bearbeitung machen.“ So sind die ermittelten Schnittwerte direkt auf Kundenbauteile übertragbar.

Das Werkzeug könnte noch mehr

Für die Versuche mit dem OptiMill-Alu-Wave wählte bavius den mit 25 mm größten Durchmesser dieses dreischneidigen Fräsers. Bei einer Spindeldrehzahl von 25.465 min-1 und einer Schnittgeschwindigkeit von 2.000 m/min wurde sukzessive die Spindelleistung erhöht. Das beste Zeitspanvolumen mit rekordverdächtigen 20 dm3/min lieferte Nut Nummer 6. Dieser Testdurchgang wurde mit einer Spindelleistung von 175 kW gefahren, wobei ein Drehmoment von 66 Nm auftrat, zugestellt wurden 30 mm. Bei Versuchen mit höheren Leistungen stoppte die Maschine. „Das Werkzeug kann man voll ausfahren, der limitierende Faktor ist die Spindel“, kommentiert Diem das Ergebnis. „Mit dem 25 mm OptiMill-Alu-Wave haben wir eine neue Dimension in der Aluminiumzerspanung erreicht. Der Fräser ist definitiv besser als alles, was wir bisher eingesetzt hatten.“

Als Auszugsicherung setzte bavius das Safe-LockTM-System ein. „In diesem Drehzahlbereich ist eine symmetrische Auszugssicherung sehr wichtig, um keine Unwucht zu erzeugen“, erläutert Tim Rohmer, Product Manager Vollhartmetall-Fräswerkzeuge bei MAPAL. Eine Weldon-Fläche, wie sie bei solchen Werkzeugen oft als Auszugssicherung angebracht werde, sei hier die falsche Lösung. Um die Laufruhe der Maschine zu gewährleisten, führe auch bei symmetrischen Werkzeugen an sorgfältigem Wuchten kein Weg vorbei.

Bei den Tests in Baienfurt war man zudem mit der erreichten Oberflächenqualität sehr zufrieden. Die Kordelgeometrie des OptiMill-Alu-Wave sorgt für optimale Spanbildung. Das polierte Nutprofil gewährleistet reibungslosen Abtransport der Späne, den die Zentralkühlung des Werkzeugs im Zusammenspiel mit der externen Kühlung in der Maschine unterstützt.

In weiteren Versuchen wurden Taschen in die Aluminiumplatte gefräst, wobei noch ein Zeitspanvolumen von 16 Litern bei sehr guten Oberflächen erreicht wurde. Für Anwendungstechniker Thomas Jungbeck und Component Manager Alexander Follenweider, die die Versuche für MAPAL begleitet haben, ist das ein Beleg für die sehr gute Dynamik des bavius Bearbeitungszentrums: „Oft bleiben andere Maschinen in den Ecken stehen und bewirken hohe Vibrationen. Das tritt bei der AeroCell überhaupt nicht auf, die fast ungebremst um die Ecken fährt.“

The tests at bavius with the new indexable insert tool NeoMill-Alu-QBig from MAPAL, for which the 50 mm diameter was selected, were also extremely positive. The aluminium high-volume milling cutter achieved a material removal rate of 18.4 dm3/min. On the machine, the milling cutter stood out with its high level of stability, smooth running and low cutting forces. For use at spindle speeds up to 35,000 rpm, MAPAL fitted the tool body with four threaded bores for fine balancing. The high-precision peripherally ground indexable inserts achieve surface finishes of Ra 0.8 µm and Rz 4 µm during rough and fine machining. They are equipped with a polished chip guiding stage to reduce frictional resistance and heat release. Weight was also saved in order to reduce centrifugal forces. “For larger diameters, milling cutters with indexable inserts are the more economical solution”, explains Heiko Pup, Product Manager for tools with indexable inserts, contrasting the NeoMill-Alu-QBig milling cutters with solid carbide milling cutters.

With a 25 mm diameter, the two systems merge. “Some of our customers always go for the more cost-efficient indexable inserts if possible, others prefer to save themselves an extra machining step and continue with the solid carbide milling cutter”, explains Stefan Diem. With different possible radii for its tools, MAPAL provides users with flexibility.

With the horizontal machining centre AeroCell 160 and the aluminium high-volume tools, bavius and MAPAL provide users with a combination that takes machining structural parts to a whole new level.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342