01.02.2018

Successfully Re-tooling Machines

re.tooling is worth it – even for small and medium-sized companies

re.tooling an existing production system can significantly contribute to the improvement of cost-effectiveness as well as productivity and the precision of a machining process. Particularly good results can be achieved when the tool, clamping solution and machining concept are precisely tailored to the machine and machining task. This is shown with the example of Stefan Plätzer Maschinenbau GmbH \(Plätzer\) that has increased the output of an existing machining centre from four to 30 parts per hour with the support of re.tooling services from MAPAL.

Quick access to new technologies

Here it may be worthwhile to bring a strong partner such as MAPAL on board that is right at the forefront with the development of the latest tool technologies. In addition, MAPAL has vast experiences in the design of machining processes and clamping concepts as well as the programming of machine tools.

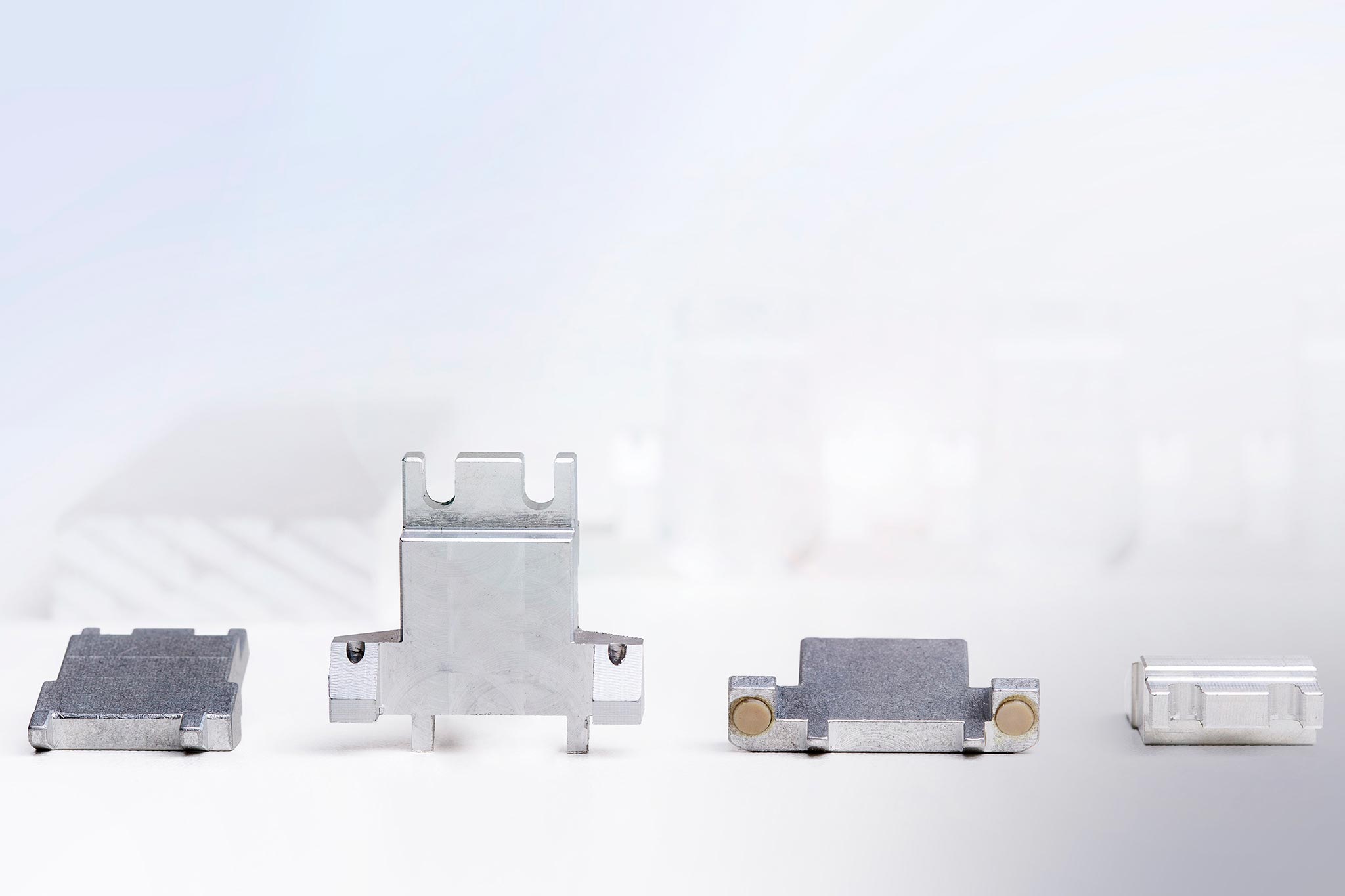

Small and medium-sized companies that specialise in the manufacturing of individual parts, small series and medium series particularly benefit from these competences. This is shown by the current project from Plätzer. The company focused primarily on improving the machining time and the process reliability for the manufacture of two types of robot grippers. The customer of Plätzer uses these grippers to securely fix tiny ceramic parts so that they can be automatically shaped as specified with a grinding wheel. The tolerance specifications are correspondingly narrow: The parallelism and squareness deviation of the areas is limited to only 0.02 mm.

Increasing production quantities require a more stable and efficient process

Halving the machining time: PCD instead of carbide

In this situation, the quality manager remembered his friend, Markus Meyer, who works at MAPAL as a Technical Consultant. At a company visit arranged at short notice, Meyer was presented with the machining process and identified a promising approach for the reduction of the productive time: changing from simple carbide to PCD tools that are characterised by significantly higher feed rates and tool lives.

In an initial step, the MAPAL sales representative suggested the use of two PCD milling cutters. The grippers were milled from solid. This is why the milling proportion and the saving potential for this machining task are high. Stefan Plätzer took up this suggestion. And with great success: Without additional optimisation measures, the machining time for one part was reduced from 15 to two minutes.

“We had stuck with the conventional technology for a long time. The tightly scheduled daily routine left us no room for a far-reaching evaluation of new technology”, remembers Stefan Plätzer. “Since we have had MAPAL by our side, we benefit from the experience and innovation of the company and its employees, among other things. In this way, we can recognise and make use of optimisation potentials much earlier.”

The quick way to a custom-made machining process

Stefan Plätzer was open-minded when Markus Meyer brought the re.tooling services for the complete gripper production into play, particularly to increase process reliability using new fixture. “For us it was important that the tools as well as the fixture could be used universally as far as possible, as we are primarily active in a segment that is characterised by single piece and small series production”, says Stefan Plätzer.

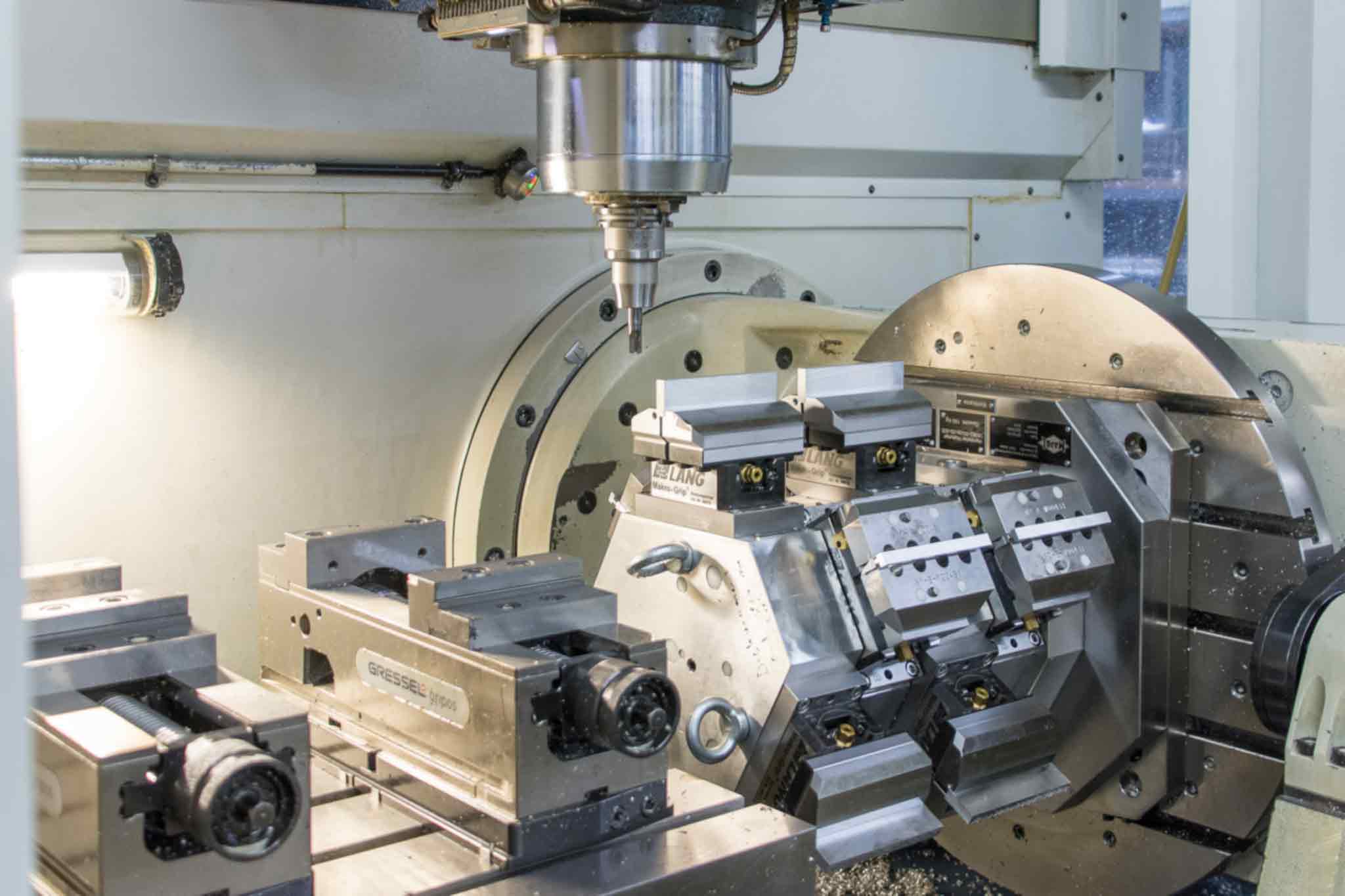

After the appropriate concept was drawn up in close coordination, MAPAL received the order for its implementation. The service team of the tool specialist undertook all the required work: Starting with the design of the machining process including clamping chuck, the design and organisation of the fixture and the machine programming on site. Specialists from the tool manufacturer also completed the running in of the process.

re.tooling provides maximum efficiency and process reliability

The result is convincing: Plätzer now manufactures 24 parts in just 48 minutes with a significantly higher degree of precision and process reliability than before. The new fixture contributed significantly to the noticeable improvement in addition to the use of the PCD tools and a custom-made solid carbide step drill from MAPAL. The clamping fixture for the first gripper type has 24 clamping stations and the one for the second gripper type has 36 clamping stations. In addition the number of clamping setups was reduced from three to two.

The time saved is so great that production of both gripper types can be realised on just one machine. Plätzer has thereby gained four weeks of machine capacity for a production quantity of 800 pieces. These are now available for new projects. Stefan Plätzer explains: “If new projects are pending, we consult Markus Meyer if required and clarify whether MAPAL can support us in being able to accept the projects at prices in line with the market. During the consultation, we experienced several times that the sales are not decisive for MAPAL. It is important for the tool manufacturer to make us ready for the future so that we can progress further as partners.”