Luft- und Raumfahrt

Hochfeste und gleichzeitig leichte Materialien sind in der Luftfahrt von zentraler Bedeutung. Durch neuartige Materialkombinationen lässt sich das Gewicht weiter senken, die Festigkeit und Korrosionsbeständigkeit erhöhen sowie eine Vereinfachung der Montage durch integrative Bauweise erreichen. Während Strukturbauteile aus Aluminium, Titan oder hochfesten Stählen auf Bearbeitungszentren oder Portalmaschinen bearbeitet werden, erfolgt die Bearbeitung in der Endmontage durch handgeführte Maschinen, Bohrvorschubeinheiten oder Roboter.

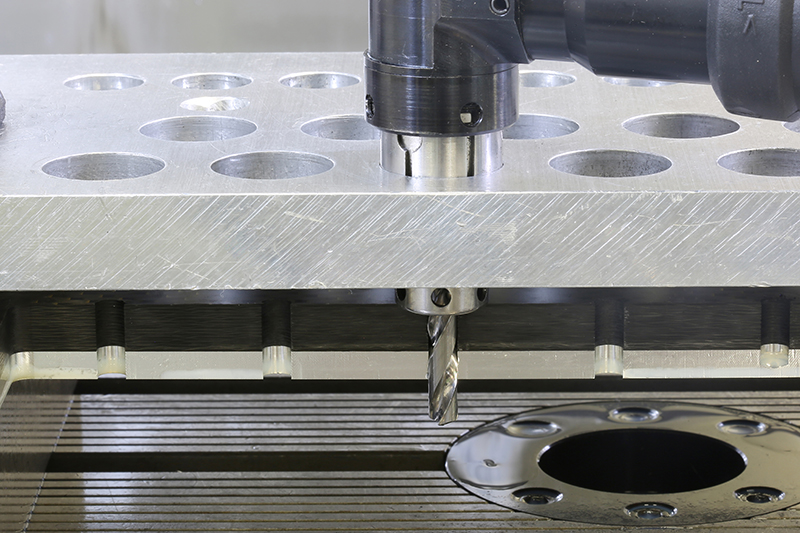

Teilefertigung

Bei der Teilefertigung erfolgt die Bearbeitung der Bauteile stationär, d.h. Bauteile werden in einer Maschine in einer oder mehrerer Aufspannungen zerspant. Während kleinere bis mittlere kubische Bauteile auf einem Bearbeitungszentrum (BAZ) bearbeitet werden können, erfordern große Bauteile spezielle Portalmaschinen.

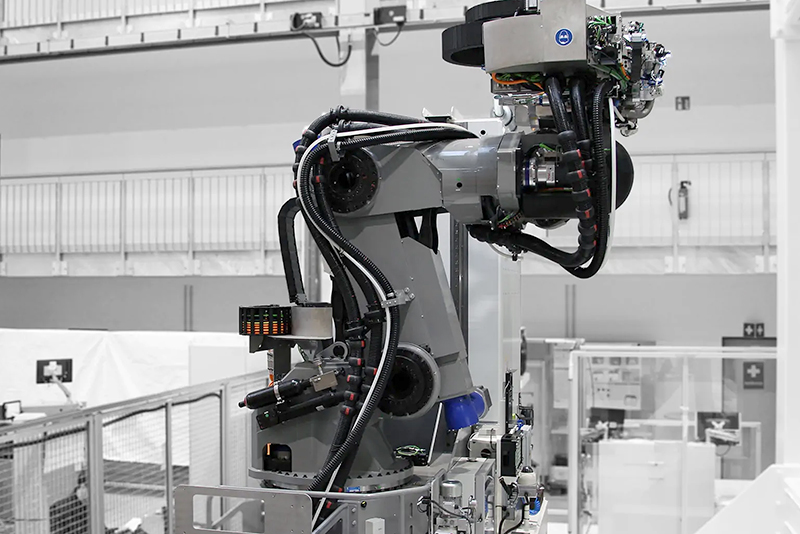

Endmontage

Bei der Endmontage eines Flugzeugs wird aufgrund der Größe des Objekts auch heute noch mit handgeführten Maschinen gearbeitet. In sogenannten Final Assembly Lines (FAL) werden zum Beispiel Nietlöcher in die Außenhaut des Flugzeugrumpfs eingebracht. Die Werkzeuge sind mit speziellen Führungselementen ausgeführt.

Weitere Artikel aus dem Bereich Aerospace

-

24.02.2026

MAPAL und bavius entwickeln Musterbauteil für Flugzeugindustrie

In einem Gemeinschaftsprojekt haben MAPAL und der Maschinenhersteller bavius ein Musterbauteil für die Flugzeugindustrie entwickelt und gefertigt.

-

24.10.2025

Portrait: MAPAL Kompetenzzentrum PKD-Werkzeuge

Mit dem Kompetenzzentrum für PKD-Werkzeuge setzt MAPAL Maßstäbe in Sachen Kundenservice, Technologie, Effizienz und Nachhaltigkeit.

-

15.10.2025

Werkzeuglösungen von MAPAL sorgen für mehr Produktivität bei Kunden

Die Steigerung der Produktivität bei den Kunden steht im Mittelpunkt von Standardprozessen für die industrielle Fertigung strategischer Bauteile.