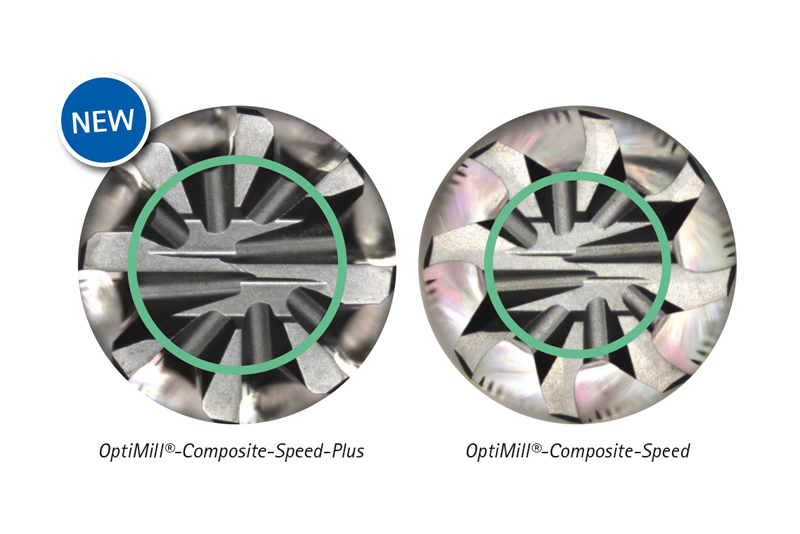

OptiMill-Composite-Speed-Plus

Seguridad de proceso en una nueva dimensión

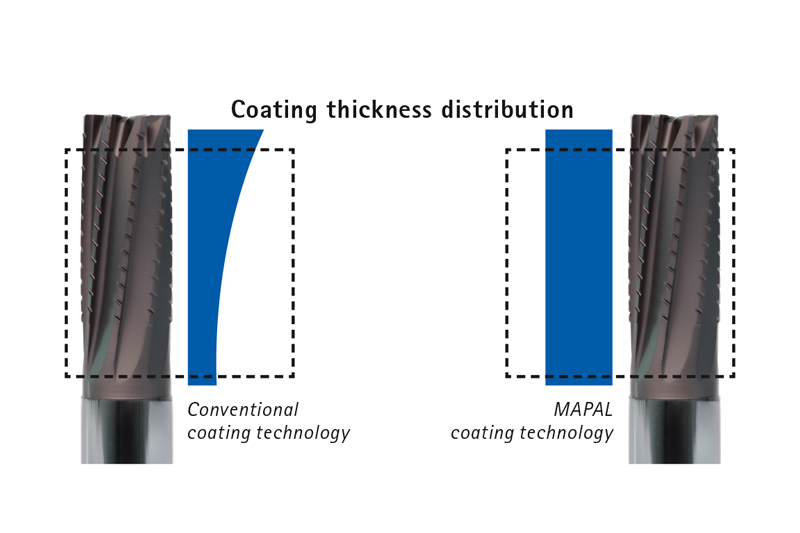

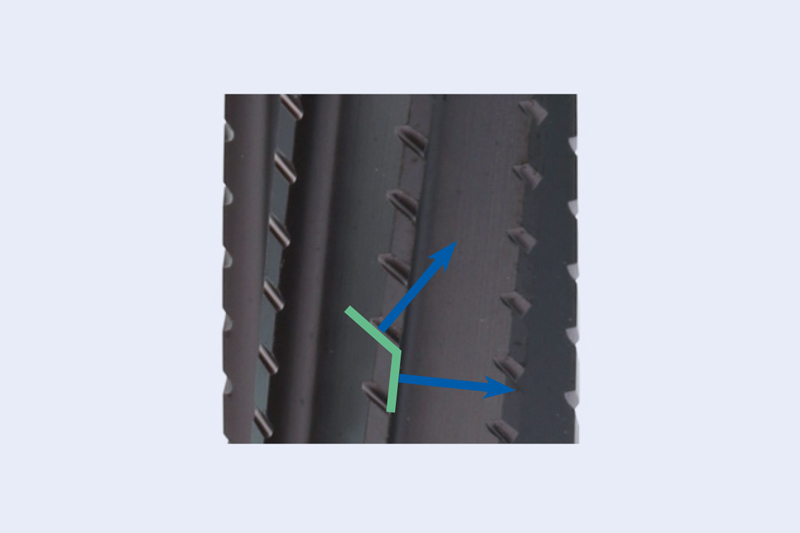

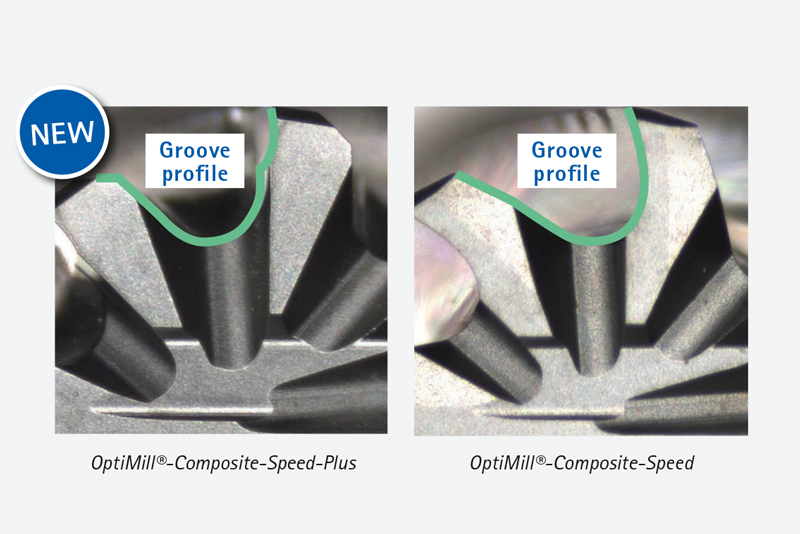

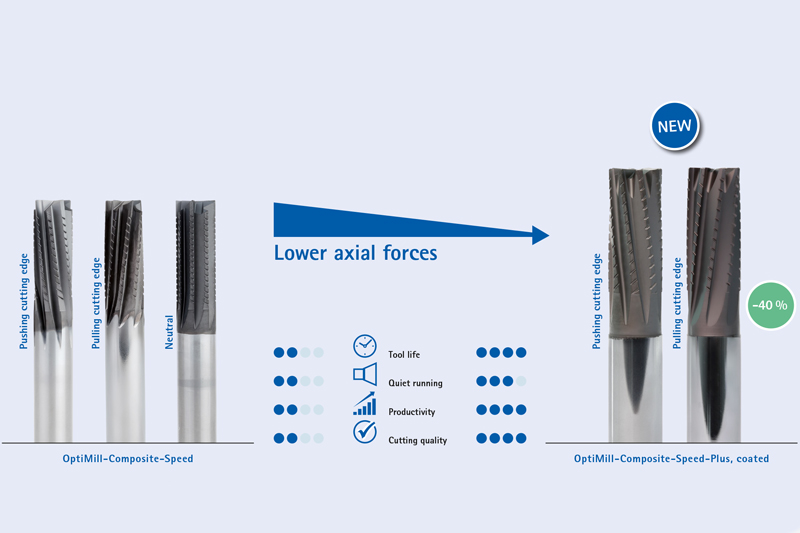

La OptiMill-Composite-Speed-Plus se distingue por un nuevo recubrimiento de diamante desarrollado por MAPAL mismo, con una distribución de capas uniforme y un elevado grosor de las capas. El aumento del diámetro del núcleo permite un incremento de 50 por ciento de la resistencia a las roturas. El perfil de ranura optimizado facilita una evacuación rápida y segura del polvo y del calor del proceso, incluso con un volumen de arranque de virutas extremadamente alto. La cuña de corte se ha optimizado especialmente para las exigencias de materiales quebradizos. La disposición especial tipo dentado de los insertos asegura una doble compresión, con lo cual se separan con seguridad de proceso las partes sobresalientes de las fibras en los bordes de la pieza de trabajo del lado superior y del lado inferior.

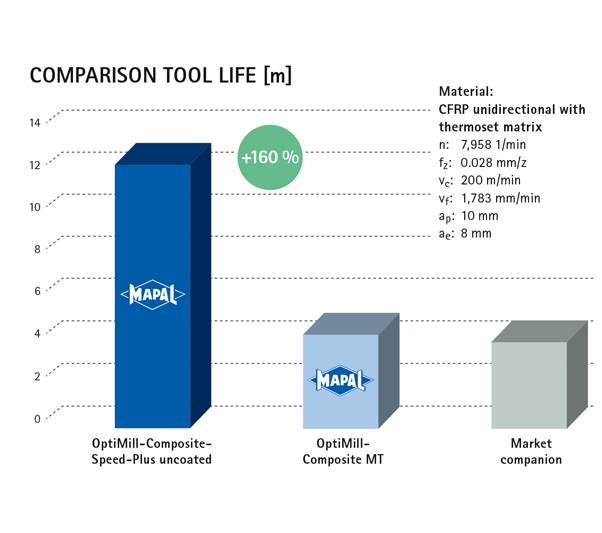

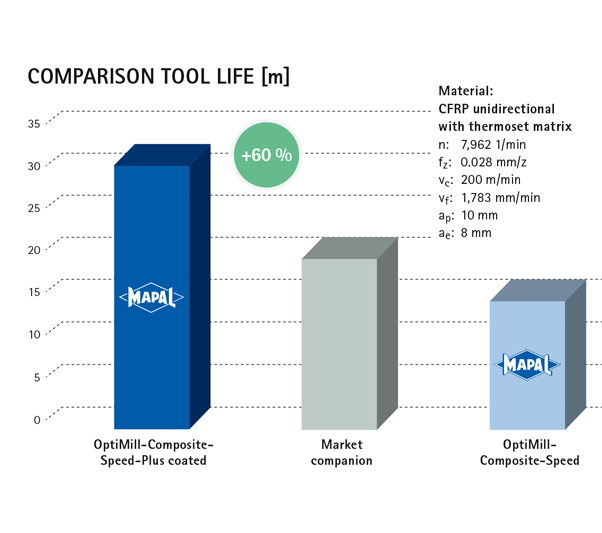

De esta manera, la OptiMill-Composite-Speed-Plus alcanza nuevas dimensiones en la seguridad de proceso. En comparación con la OptiMill-Composite-Speed se logran periodos de vida útil 20 por ciento mayores.

お客様のメリット

生産性を高める新しいツールデザイン

Aperçu des variantes

OptiMill-Composite-Speed-Plus

Fraises à dresser, revêtues

- Premier choix pour de bonnes conditions de process

- Rapports d'usinage rigoureux

- Adapté à des exigences de productivité élevées

- Plage de diamètre : 4,00 - 20,00 mm

- Avec arête de coupe tirante/poussante

OptiMill-Composite-Speed-Plus

Fraises à dresser, non revêtues

- Premier choix pour des conditions de process marginales difficiles

- Résistance aux vibrations

- Adaptées pour les matériaux peu abrasifs, tels que le plastique renforcé de fibre de verre et le plastique renforcé de fibre naturelle

- Plage de diamètre : 4,00 - 20,00 mm

- Avec arête de coupe tirante/poussante