Ausbildung bei MAPAL

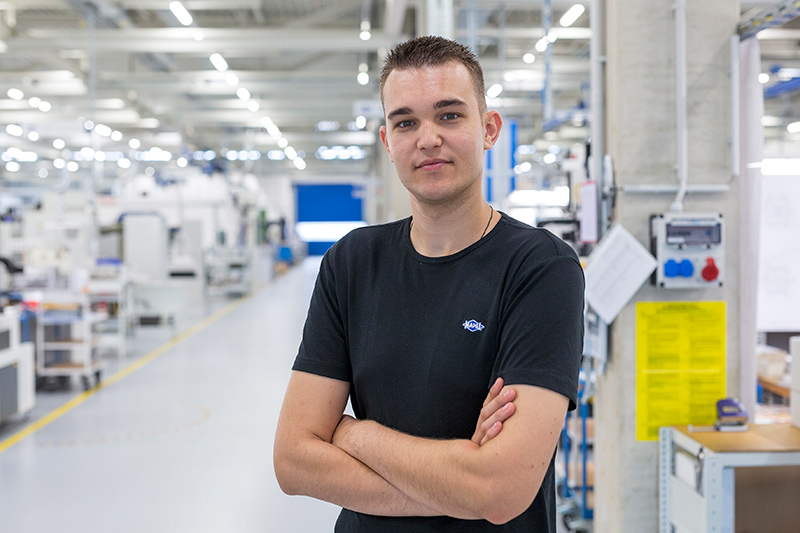

Lukas Bodi erzählt, was er in seiner Ausbildung zum Industriemechaniker erlebt

Wenn im Werk ein Druckluftschlauch pfeift oder ein Ölskimmer klemmt, ist er meist schon unterwegs. Als Auszubildender für Industriemechanik hat Lukas Bodi bei MAPAL ITS in Eppingen allerhand zu tun.

„Zu meinen Kernaufgaben gehört die Wartung und Instandhaltung von Geräten und Maschinen, aber auch die Zerspanung“, beschreibt Lukas sein vielseitiges Tätigkeitsfeld. Nach der Schulzeit hat er zunächst eine Ausbildung zum Koch erfolgreich abgeschlossen und im Anschluss ein FSJ absolviert, bevor er sich 2018 für eine Ausbildung zum Industriemechaniker entschied. Innerhalb eines Praktikums habe er einfach gemerkt, dass ihm dieser Beruf richtig Spaß mache und ihm interessante Perspektiven biete. Daraufhin bewarb er sich auf einen Ausbildungsplatz bei MAPAL in Eppingen. An diesem Standort werden Aussteuer- und ISO-Sonderwerkzeuge in einer der weltweit größten und modernsten Fertigungsstätten für diese Produkte hergestellt. Lukas ist ausschließlich im produktionseigenen Ausbildungszentrum tätig und heute mehr denn je überzeugt, den richtigen Schritt gegangen zu sein. „Ich war mir anfangs nicht sicher, ob ein metallverarbeitender Beruf zu mir passt und wurde positiv überrascht. Ich finde es megainteressant, und es hat mich echt verblüfft, wie komplex das alles ist. Und dass man jeden Tag etwas Neues lernen kann“, bringt er seine Begeisterung zum Ausdruck.

Abwechslung trifft Routine

Jeder Tag hält seine Überraschungen bereit. Mal muss eine Maschine gewartet oder eine pneumatische Anlage gerichtet werden. An einem anderen Tag wiederum fräst Lukas kurzfristig Teile zur Montage oder dreht Werkstücke auf der CNC-Maschine. Eben diese Vielschichtigkeit fasziniert ihn so an seiner Ausbildung. Ein typisches Projekt ist für ihn die Wartung einer Drehmaschine, wenn diese zum Beispiel quietschende Geräusche verursacht oder generell nicht rund läuft. Meist muss er dann den Riemen austauschen, Ölstand, Gerätspindel und Halter überprüfen sowie das Kühlmittel absaugen und wechseln. Gerade die älteren konventionellen Maschinen sind sehr pflegeintensiv. „Die muss man täglich schmieren, alle ein bis zwei Wochen das Kühlmittel nachfüllen und gelegentlich die Filter wechseln. Wenn man gut auf sie aufpasst, sind sie aber sehr robust und langlebig“, weiß Lukas.

Die Herausforderung sieht er darin, eine Maschine, die er auseinandergebaut hat, auch wieder zusammenzubauen, ohne eine Schraube oder ein Kabel zu vergessen. Schließlich muss jedes Teil exakt wieder in dieselbe Position gebracht werden, damit die Maschine präzise läuft. Hierzu dokumentiert er jeden Arbeitsschritt akribisch mit Fotos und Notizen zur Nachverfolgung. Das kostet zwar etwas Zeit und Konzentration, aber diese Disziplin lohnt sich meist hinten raus und hat ihm schon die ein oder andere Mehrarbeit erspart.

Rejoins-nous !

Entry opportunities for school pupils

School-leaving qualifications within reach: together as you embark on your working life & career

You’ll soon be starting your professional career – and with it a new chapter in your life.

Find out which training and study opportunities you have at MAPAL as well as what the requirements are and which dates and formalities you need to observe. We support you with helpful tips for making your application strong.