26.10.2023

Investing in health, sustainability and quality

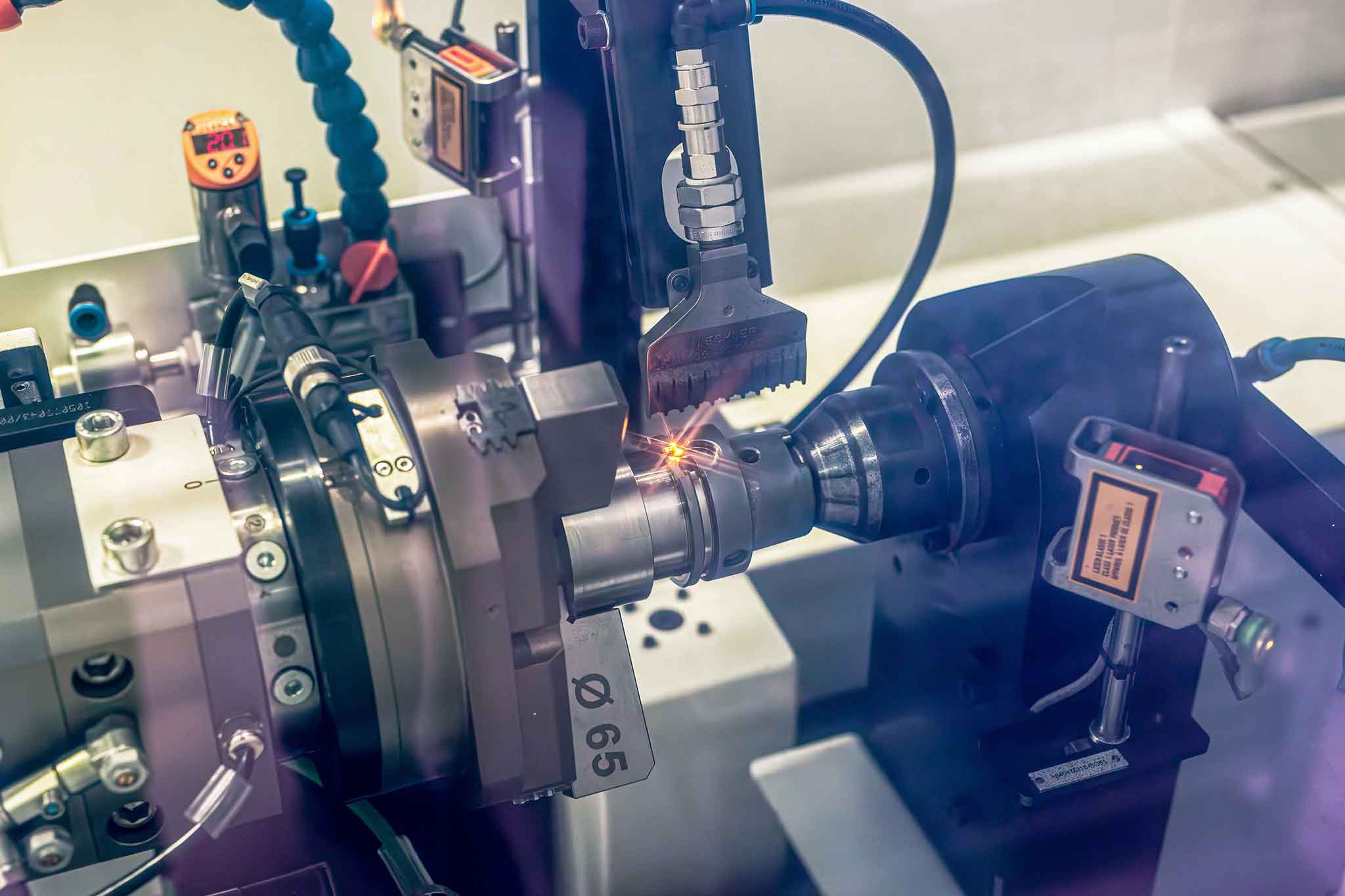

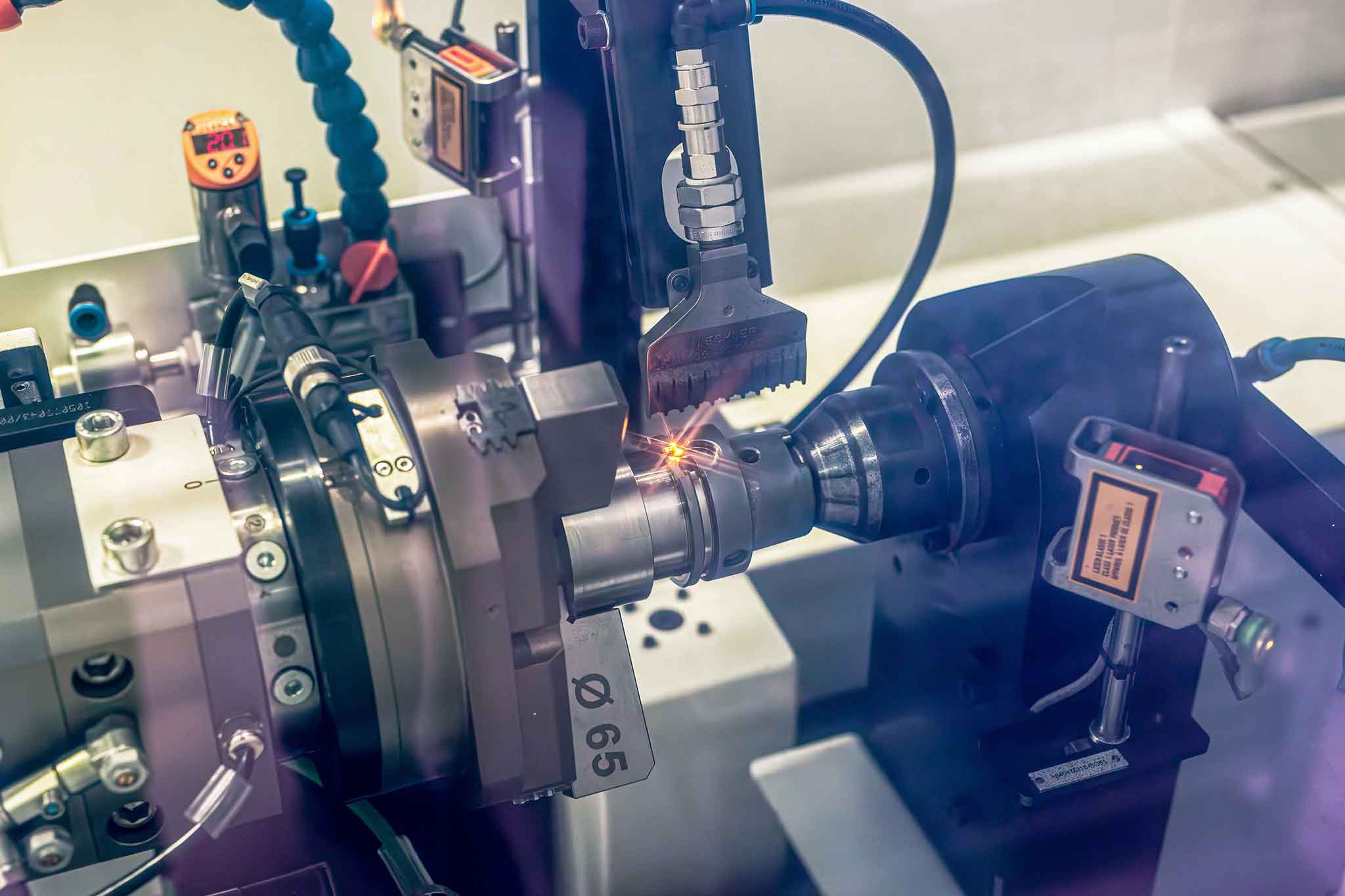

New laser hardening system for series production

MAPAL has commissioned a new, unique laser hardening system in manufacturing, which will gradually take over all the tasks that were previously carried out in a salt bath in the hardening workshop. This not only has advantages in terms of quality, but also protects the health of the employees as well as the environment.

Health risk and high gas consumption

Research collaboration on laser hardening of connections

One alternative to the salt bath is laser hardening. The experts at MAPAL converted an existing machine for the purpose of hardening connections using a laser. The machine was originally designed for laser deposit welding. However, it was not clear at the time whether the process would be robust enough for the connections. To gauge this, MAPAL carried out research together with the Machine Tool Laboratory, abbreviated to WZL, at RWTH Aachen University. Together, they investigated torsion resistance, which is how resistant a laser-hardened connection is to torsion. This yielded positive results. Laser hardening is able to replace the salt bath when it comes to connections.

For about two years now, MAPAL has been using the converted machine to harden all the connections with MAPAL’s own module system. The machine’s laser heats the tempered steel to such a degree that when it cools down, the same structural changes occur as in the salt bath and the connection is hardened accordingly. This process is possible because tempered steel is a so-called self-quenching steel. This means that the tempered steel draws the heat generated by the laser inwards very quickly and thus cools down again very quickly – in other words, it quenches itself. Only then do the crucial structural changes take place. However, this process is very complicated and requires too much for hardening workpieces in series production. MAPAL went in search of a solution and found the ideal partner in the machine manufacturer EMAG.

A world’s first

Together, the experts from both companies have developed a machine that hardens the hollow shank taper both inside and out by laser –without much adjustment and clamping effort. After a lot of work and two years in the making it was ready – the only machine in the world so far that hardens tool connections with a laser. It is located in MAPAL’s manufacturing facility in Aalen.

Currently, all current connections are being gradually converted to the new process. By the end of the year, all connections and sizes are to be hardened on the machine. Then it’s goodbye to the salt bath in the hardening workshop and with it the adverse working environment and all the dangers that come with it.

Advantages, advantages, advantages

The new unit is therefore not only an advantage to the health of the employees, but also in terms of the quality of the connections. After all, the laser is much more precise than the salt bath when it comes to hardening. All upstream and downstream processes benefit from this. As a result, there are significantly fewer distortions in the material. It is no longer decisive exactly when the hardening procedure is incorporated into the process. And it is great that the work can be automated – after all, it is becoming more and more difficult to find employees who want to work in the hardening workshop or take on the evening or night shifts. Although at the moment the workpieces are still inserted into the machine by hand, this will soon be done by a robot. Then the process can be automated as far as possible, especially during the evening and night shifts.

In addition to the advantages mentioned already, the machine also has a measurable advantage in terms of sustainability. The EMAG machine saves more in the long run when you compare the 420,000 kilowatt hours of gas consumed by the molten salt with the 60,000 kilowatt hours of electricity consumed per year when hardening by laser. Everything considered, the machine therefore makes a huge contribution to more health, sustainability and quality.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342