02.07.2021

Roboterzelle – Zwei Azubis rüsten auf

Was zwei Azubis aus einem Sechs-Achs-Universalroboter gemacht haben.

Ohne Roboter geht in der Fabrik von morgen nichts mehr. Ohne geschulte Fachkräfte, die die smarten Helfer bedienen, auch nicht. Bei MAPAL wird der Nachwuchs schon heute qualifiziert. Zwei Azubis haben eine Roboterzelle für das werkseigene Ausbildungszentrum umgebaut und erweitert.

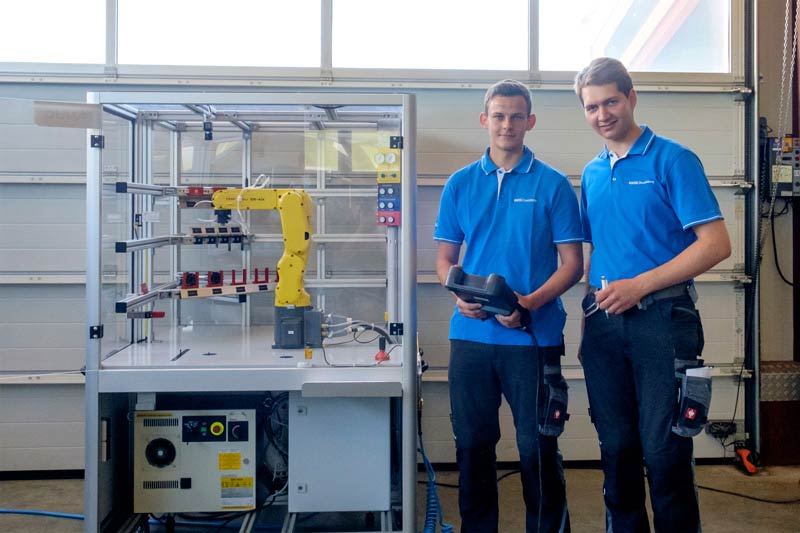

Im Ausbildungszentrum von MAPAL steht sie nun, die neue Roboterzelle. Für Marvin Schuster (18) und Philipp Raab (19), beide sind in der Ausbildung zum Mechatroniker, ist das Gerät das ideale Lernobjekt. Denn ein Roboter vereint alle Disziplinen, die sie in ihrem späteren Beruf beherrschen müssen: die Mechanik, die Elektrotechnik und die Informatik.

Schon Anfang 2020 trifft die Bearbeitungszelle im Ausbildungszentrum ein: Ein großer, gläserner Kasten, der auf einem fahrbaren Wagen steht. In der Zelle befinden sich der Roboter sowie verschiedene Komponenten, die ein Roboter braucht, um bestimmte Aufgaben auszuführen. In Betrieb nehmen lässt sich das Gerät vorerst nicht, denn wenig später kommt es zum Lockdown und das Team des Ausbildungszentrums muss alle Auszubildenden für mehrere Wochen ausschließlich digital unterrichten.

Die Roboteranlage wird begutachtet

Aus Plänen werden Taten

Das Team beschließt, die Zelle zu erweitern und umzubauen:

- Es soll möglich sein, betriebsspezifische Abläufe in der Werkzeugfertigung zu simulieren, als Vorbereitung auf den künftigen Einsatz von Robotern in einzelnen Produktionsbereichen.

- Der Roboter soll so einfach zu bedienen sein, dass auch Anfänger ohne Vorwissen gezielt klarkommen.

Gut ein Jahr später stellten Marvin und Philipp, gemeinsam mit Martin Ernsperger, Tobias Dambacher und Uwe Heßler, Leiter der Aus- und Weiterbildung bei MAPAL, das Ergebnis ihrer Arbeit vor. Dazu luden sie die Vertreter der am Projekt beteiligten Unternehmen sowie die Lehrer der Technischen Schule zu einem Vor-Ort-Termin ein. Marvin und Philipp hatten sich zunächst mit der Anleitung zum Betrieb der Roboterzelle beschäftigt. Sie fügten eigene Texte sowie erklärende Bilder ein, um sie leichter verständlich zu machen. „Wir konnten uns dadurch gut in die Materie einarbeiten.“ Im nächsten Schritt erweiterten sie das Gehäuse der Roboterzelle um das Doppelte. Nun war Platz für neue Komponenten: Eine montierbare Maschinentür mit Kollisionserkennung, Nullpunktspannsysteme im Kleinformat, Ablagesysteme für Greifer und Werkzeuge, einen Werkzeugwechseladapter, ein Lasermesssystem, einen zweiten Schaltschrank sowie Taster und Schalter als Ergänzung zum Bedienpanel.

Die mechanischen Teile fertigten Marvin und Philipp im Ausbildungszentrum selbst an. Bei der Elektronik und der Programmierung der Software sowie bei der Auswahl zusätzlicher Komponenten arbeitete das Team eng mit der Technischen Schule Aalen sowie den Firmen Fanuc und Mössner zusammen. Mössner ist Anbieter von Sonderlösungen in den Bereichen des Maschinenbaus, der Automatisierungstechnik sowie der Robotik.

Mechanisch, per Steuerung und automatisch

Ein Projekt, das sich gelohnt hat

Marvin und Philipp sind stolz auf ihre Leistung und konnten sich viel Wissen rund um den Roboter aneignen. Wie wichtig das ist, wissen die Experten. Die Automatisierung und der Einsatz von Robotern werden die Produktion langfristig verändern. Umso wichtiger sei es, den Nachwuchs frühzeitig vorzubereiten. Das Thema müsse noch stärker in Schule und Ausbildung verankert werden. „MAPAL hat gezeigt, wie es geht“, sagte Jens Mühlegg, Technical Sales Support Universities and Education Centers bei Fanuc. Studiendirektor Thomas Dietrich und Jens Kinzler, Lehrer Abteilung Metall, beide unterrichten an der Technischen Schule Aalen, bezeichneten die Zusammenarbeit als ein Musterbeispiel für eine gelungene Lernkooperation. „Das ist Lernen am realen Objekt“ kommentierte Christian Kunz, Leiter Forschung und Entwicklung bei Mössner, den gelungenen Umbau.

Die aufgerüstete Roboterzelle wird nun auf breiter Front im Einsatz sein: Alle Auszubildenden, ob zum Zerspanungsmechaniker, zum Industriemechaniker oder zum Mechatroniker, werden im Ausbildungszentrum von MAPAL an diese innovative Technologie herangeführt.

Philipp und Marvin stehen derweil in ihren Abschlussprüfungen. Ihre Ausbildungszeit wurde wegen guter Leistungen um ein halbes Jahr auf drei Jahre verkürzt. Und Tobias Dambacher will sich weiterqualifizieren. Im Herbst beginnt er die Ausbildung zum Techniker in der Fachrichtung Mechatronik und Automatisierungstechnik. Die Schule hat ihm eine Aufnahmezusage erteilt.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342