-

1 / 6

超硬ソリッドバリ取りツール

特殊な球面形状のこのツールは、サーキュラーミーリングにより、メイン穴と取付け穴の入口と出口をバリ取りするために使用されます。

-

2 / 6

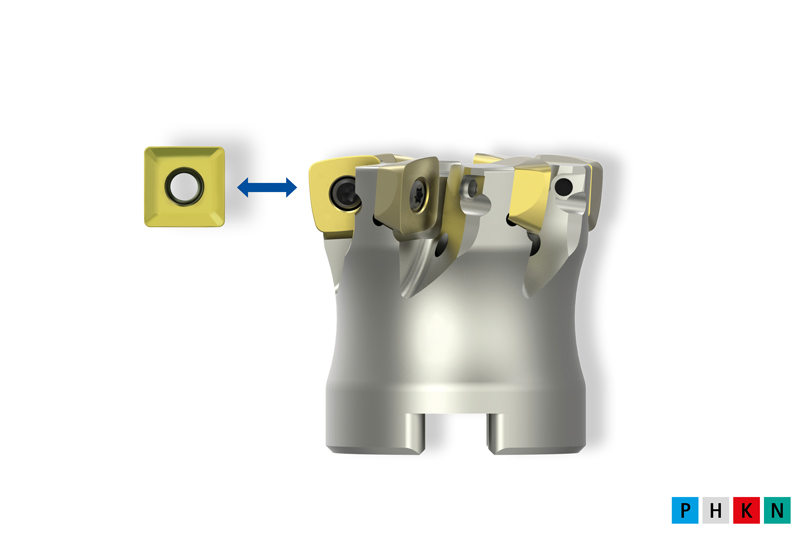

NeoMill-Titan-2-Corner

- 高い加工能率

- スムーズな加工

- 様々なコーナーRの切れ刃が使用可能

- 様々な工具材種が利用可能

-

3 / 6

MEGA-Speed-Drill-Titan

- 従来のソリューションと比較して、工具寿命が30%向上

- 高い切削速度と送り速度を実現する加工のスペシャリスト

- 短いサイクルタイム

-

4 / 6

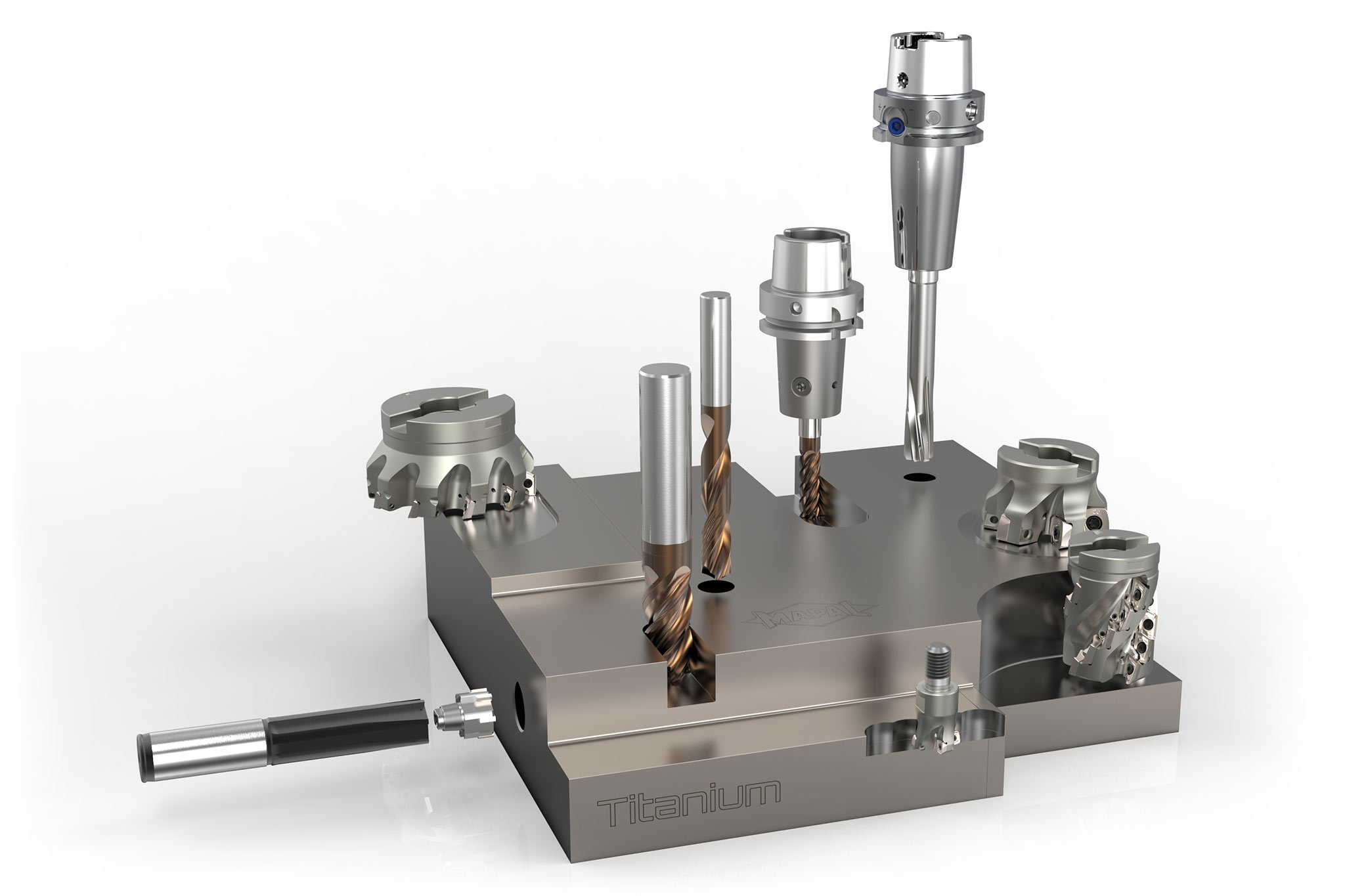

ヘッド交換式TTDトリタンドリル、特殊ドリル、ボーリングバー

- 最初の接合板のパイロット加工用ヘッド交換式TTDトリタンドリル

- 接合板を両側から中仕上げ加工するために、ネックにガイドエレメントを追加した特殊ドリル

- メイン穴の片側からの精密仕上げ加工用ベアリングガイド付きボーリングバー

-

5 / 6

OptiMill-Titan-HPC

工具寿命が35%向上

粗加工、中仕上げ加工、仕上げ加工に最適なソリューション

優れた価格性能比

ミルチャック、HBシステムに最適

最適化されたピッチ(安定した切削、スムーズな加工)

安定性を高めるウェブテーパ

-

6 / 6

OptiMill-Tro-Titan

- 従来のソリューションと比較して、工具寿命が10 %向上

- 高い材料除去率が可能

- 不等ピッチの切れ刃

- 堆積物を防ぐ特殊コーティング

- 最適な切り屑排出のために特別に設計された切り屑排出溝

-

-

-

-

-

-