Produzione di grandi serie con utensili combinati per esigenze e produttività più elevate

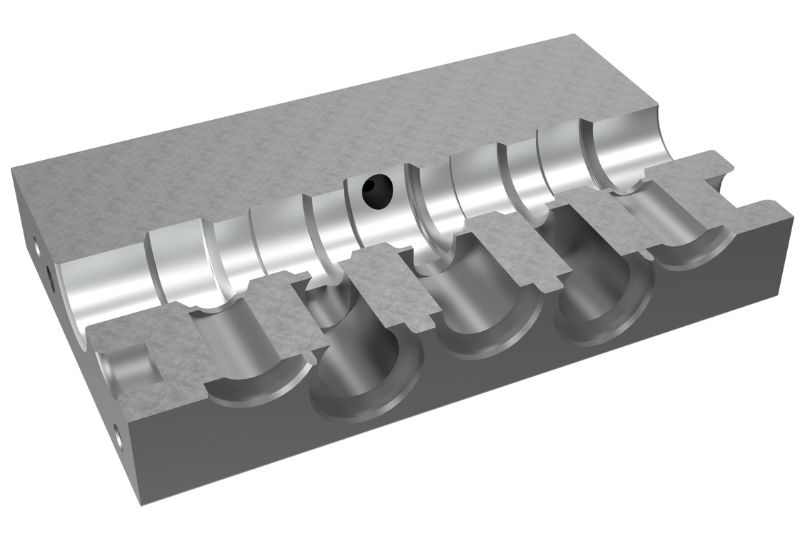

Corpo valvola AlMgSi-T6

Situazione di partenza del cliente

- Quantitativi molto elevati

- Elevati requisiti per tempi di ciclo

- Elevati costi orari

- Elevata necessità di sicurezza dei processi

- Elevati requisiti di qualità per le tolleranze di superficie, forma e posizione

- Lavorazione il più possibile priva di bave/rigature

Particolarità della soluzione

- Rottura dei trucioli ideale grazie a speciali geometrie di taglio

- Superfici e rapporti di contatto perfetti grazie agli utensili di finitura in PCD di alta qualità (Rz = 1 µm)

- Utensili combinati per un’eccellente progettazione del processo e una riduzione ottimale dei tempi di ciclo

Punti salienti dell’utensile per corpi valvole pneumatiche

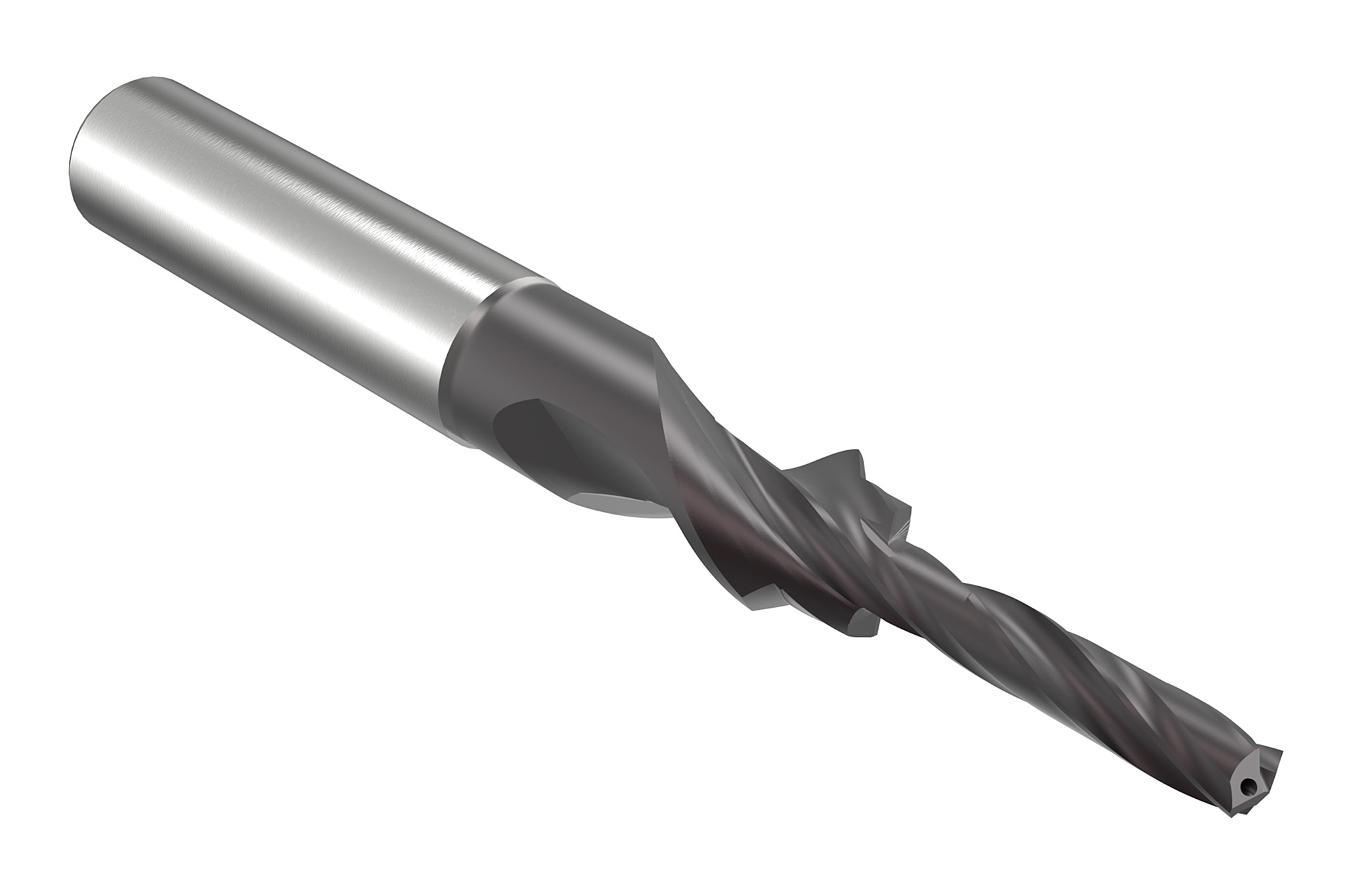

Forature a gradino

- Utensili a gradino in metallo duro integrale con speciale tecnologia multi-fase e gradino di convoglio dei trucioli per un controllo ideale degli stessi e una frequente riaffilatura

Soluzione unica per profili conici

- Punta a gradino in PCD come soluzione unica per la lavorazione affidabile di profili conici

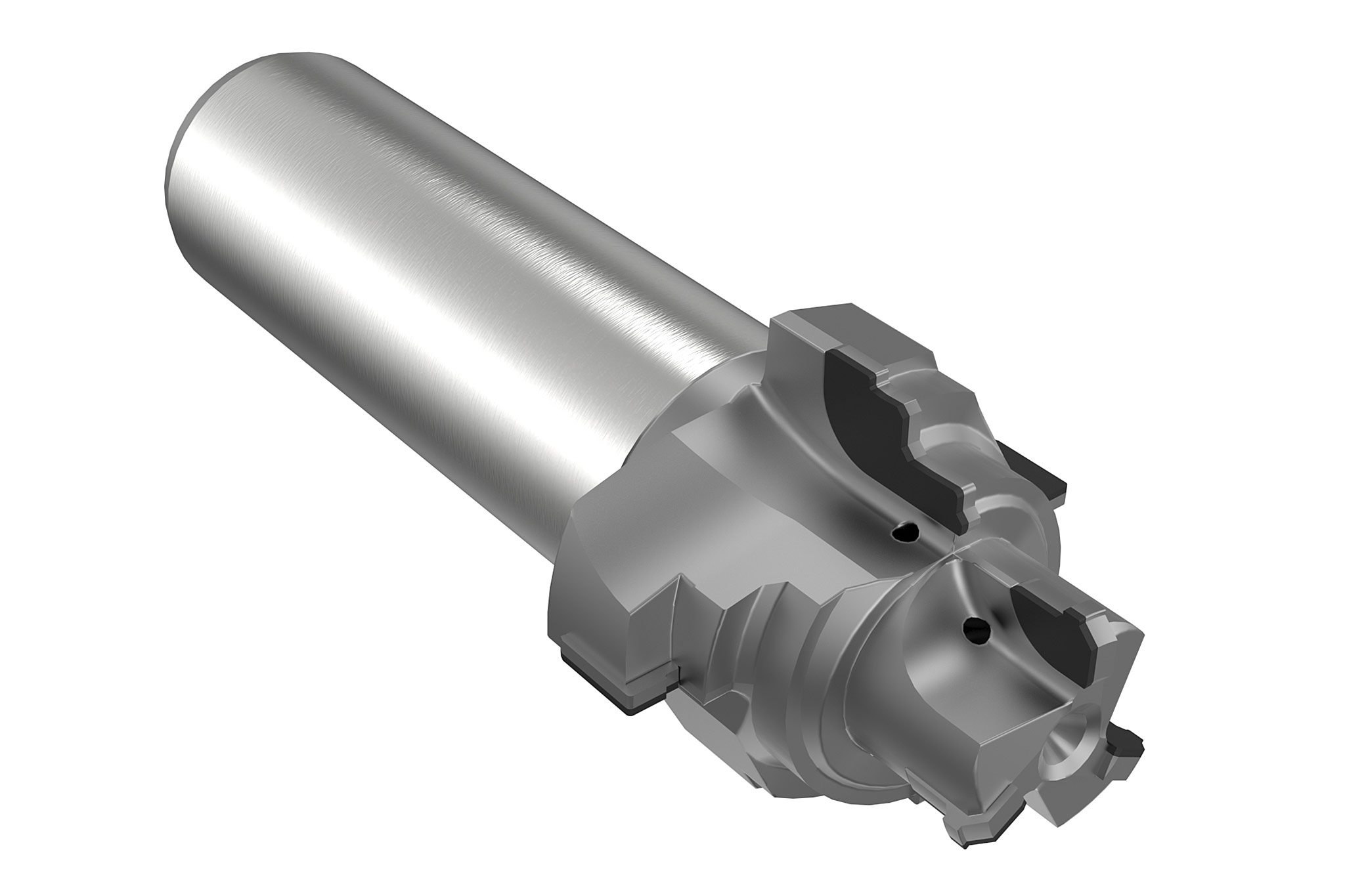

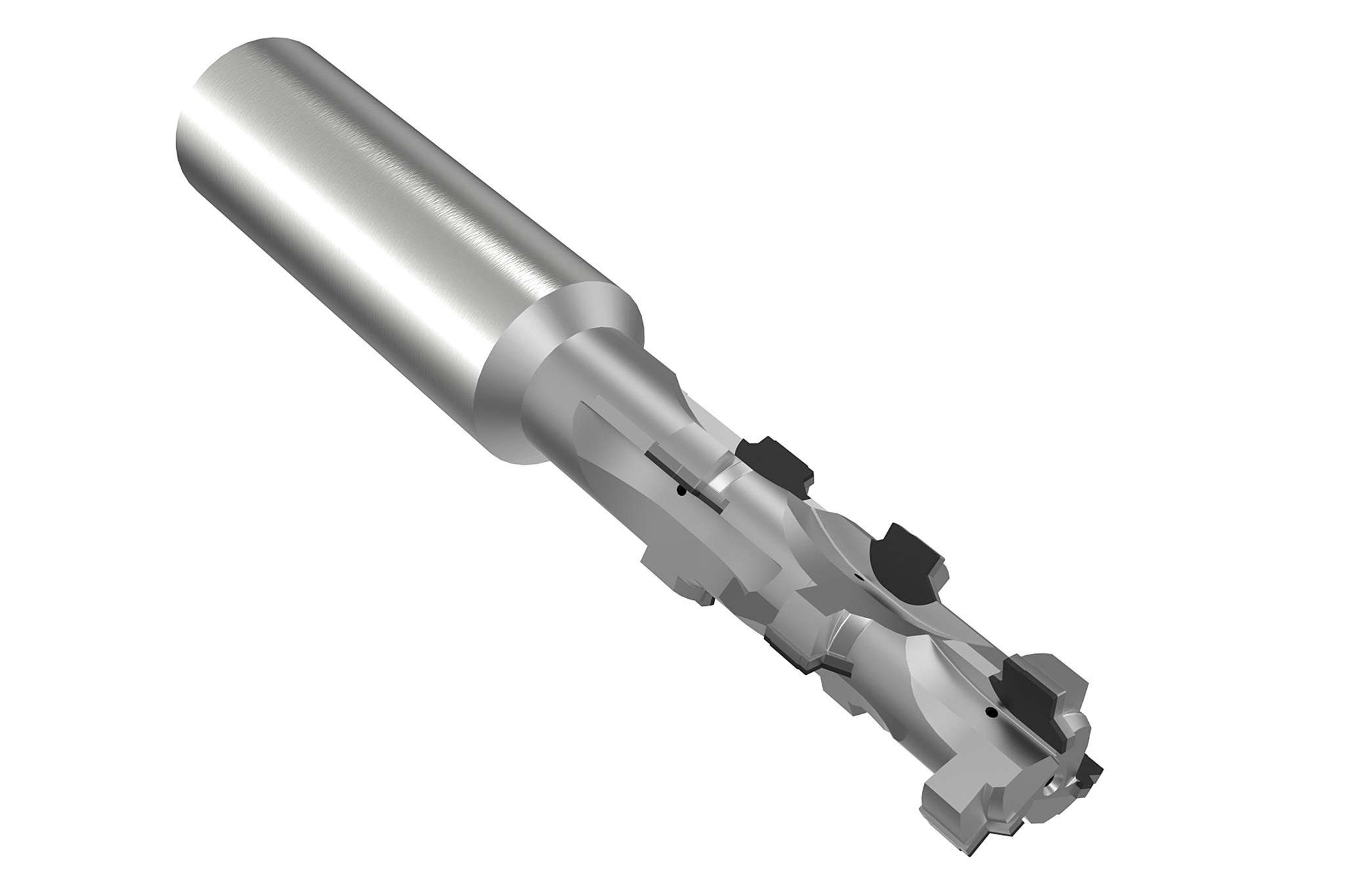

Lavorazioni di profili

- Utensile combinato in PCD multistadio

- Massima produttività e coassialità per lavorazioni di profili estremamente complessi

Lavorazione delle gole

- Fresa circolare in PCD per la massima qualità della superficie e spigoli all’interno del foro cursore perfettamente calibrati

Vantaggi

- Processi accuratamente calibrati tra prelavorazione e lavorazione di precisione

- Tempi non produttivi ridotti

- Risparmio sui tempi di ciclo con un parallelo aumento della qualità

- Aumento della sicurezza dei processi nella produzione di serie

- La pluriennale esperienza nello sviluppo e nella produzione di utensili in PCD o in metallo duro integrale consente di concepire il processo ideale in funzione delle esigenze