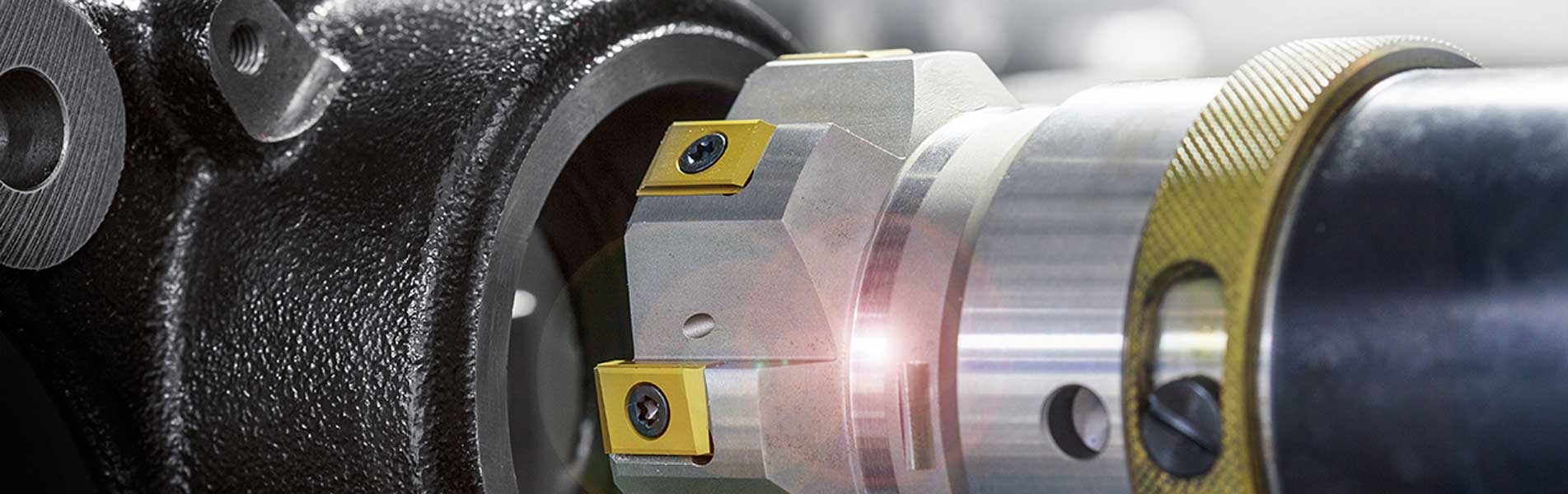

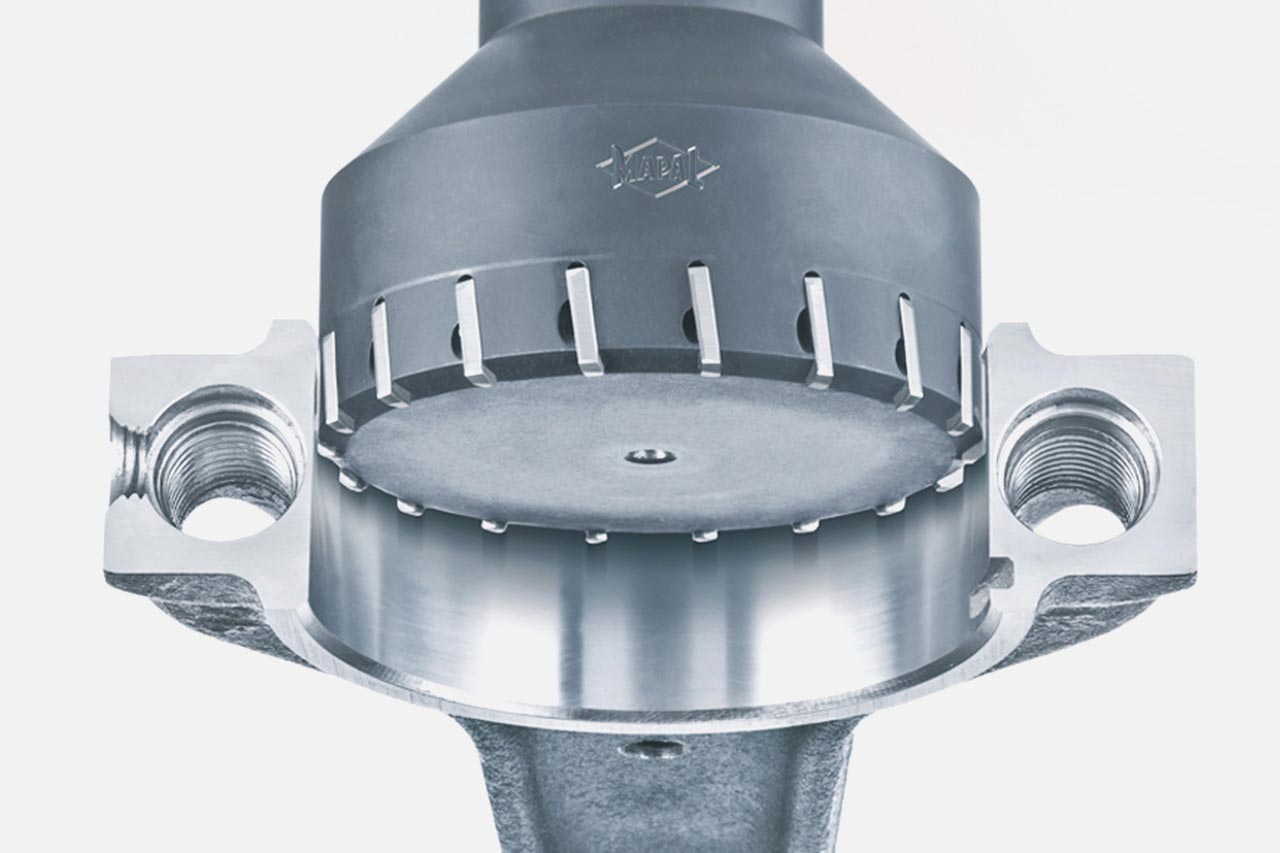

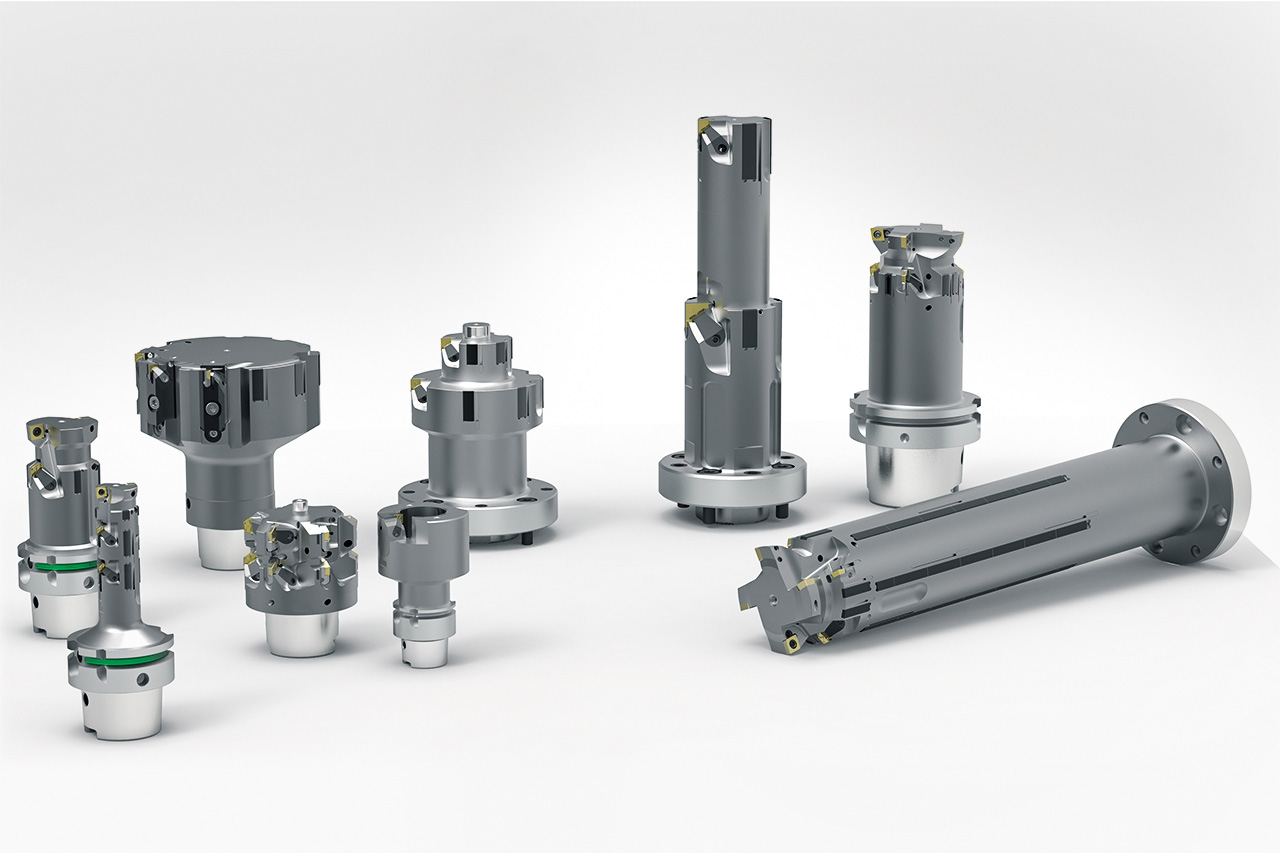

Competenza in alesatura e barenatura di precisione

Gli utensili per la lavorazione di precisione di fori rappresentano la competenza principale di MAPAL. La storia di grande successo, che ancora oggi MAPAL continua a scrivere nella lavorazione fine di forature, ha avuto inizio nell'anno 1954 con il primo "prototipo" di alesatore. Grazie all'esperienza decennale, al costante sviluppo e all'ottimizzazione delle soluzioni utensili, MAPAL è oggi in grado di offrire, oltre a soluzioni speciali su misura, anche un vasto assortimento standard di utensili per alesatura e barenatura.