Nuova geometria rompitruciolo per la barenatura di precisione

Nuova soluzione per l’asportazione truciolo di acciai a truciolo lungo

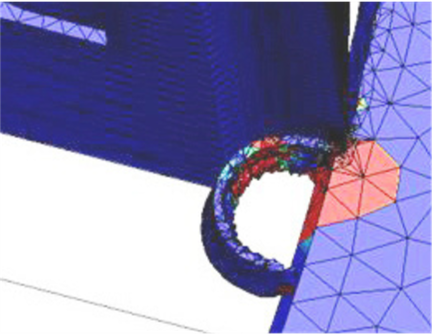

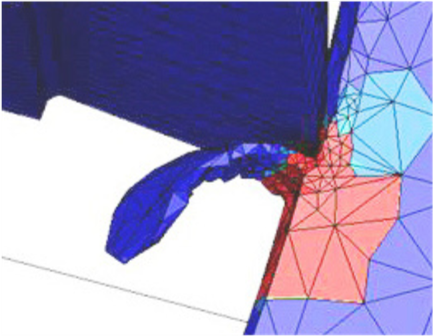

Nella lavorazione dei metalli, la formazione dei trucioli gioca un ruolo fondamentale per quanto riguarda la sicurezza dei processi, la durata degli utensili e la qualità delle superfici. La formazione controllata dei trucioli è fondamentale soprattutto nella lavorazione di finitura di acciai non legati, legati e inossidabili.

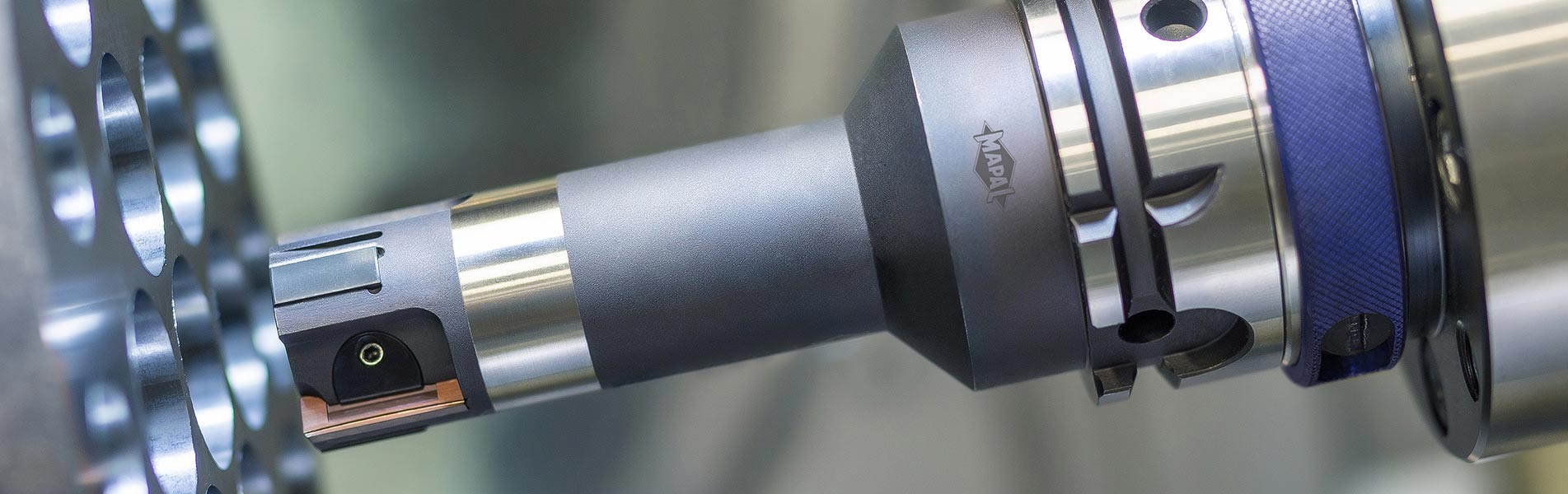

MAPAL presenta la nuova geometria rompitruciolo standardizzata per punte da microforatura, una soluzione innovativa che coniuga precisione tecnica e vantaggi economici.

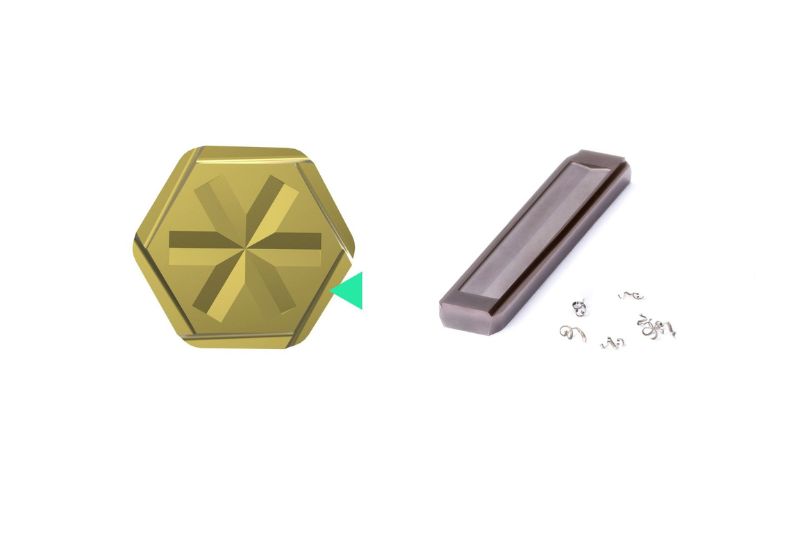

La geometria dell’angolo di taglio e dell’angolo di spoglia, definita con precisione, è ottimizzata in base ai parametri di taglio e alle profondità di passata assiale. Ciò consente una formazione controllata dei trucioli, anche con materiali difficili.

I vantaggi per l’utente sono evidenti: asportazione ottimale dei trucioli, basso sviluppo di calore ed elevata stabilità di processo.

Questa tecnologia non solo contribuisce all’elevata qualità dei pezzi lavorati, ma anche all’efficienza della produzione. I tempi di fermo macchina ridotti, la minore usura degli utensili e l’elevata precisione dimensionale garantiscono notevoli vantaggi in termini di costi.

MAPAL trasforma la sua lunga esperienza nello sviluppo dei rompitrucioli in una soluzione per la produzione in serie, disponibile a magazzino a partire dall’autunno 2025 con geometrie e rivestimenti definiti.

/Design-ohne-Titel-7-.jpg)

/Design-ohne-Titel-8-.jpg)

/Design-ohne-Titel-9-.jpg)