Competênvia em perfuração total, alargar e rebaixar

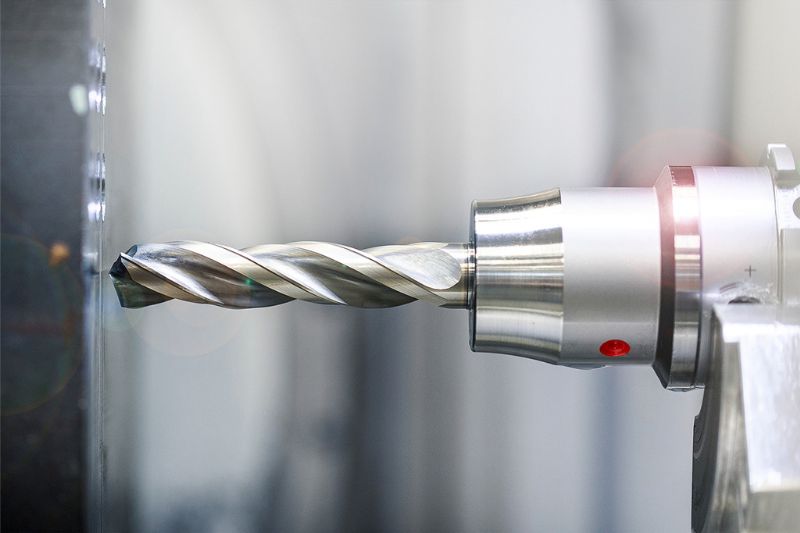

Partindo da ênfase na fabricação de ferramentas especiais para soluções de usinagem específicas para o cliente, a MAPAL desenvolveu um abrangente programa padrão para perfuração total, alargamento e rebaixamento.

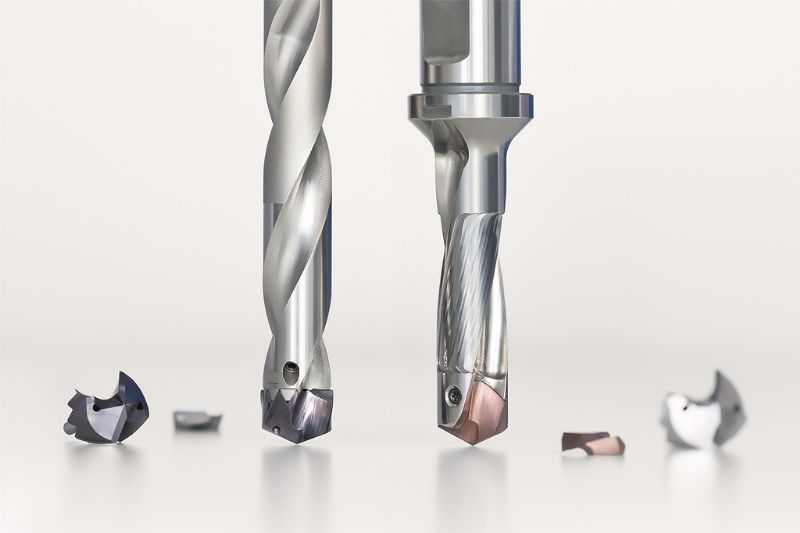

A MAPAL é um dos maiores fornecedores de ferramentas de metal duro em nível mundial. O programa de brocas de metal duro engloba soluções para a usinagem econômica e com segurança de processo de praticamente qualquer material, complementado com modernos sistemas de cabeça substituível para a mais alta rentabilidade.

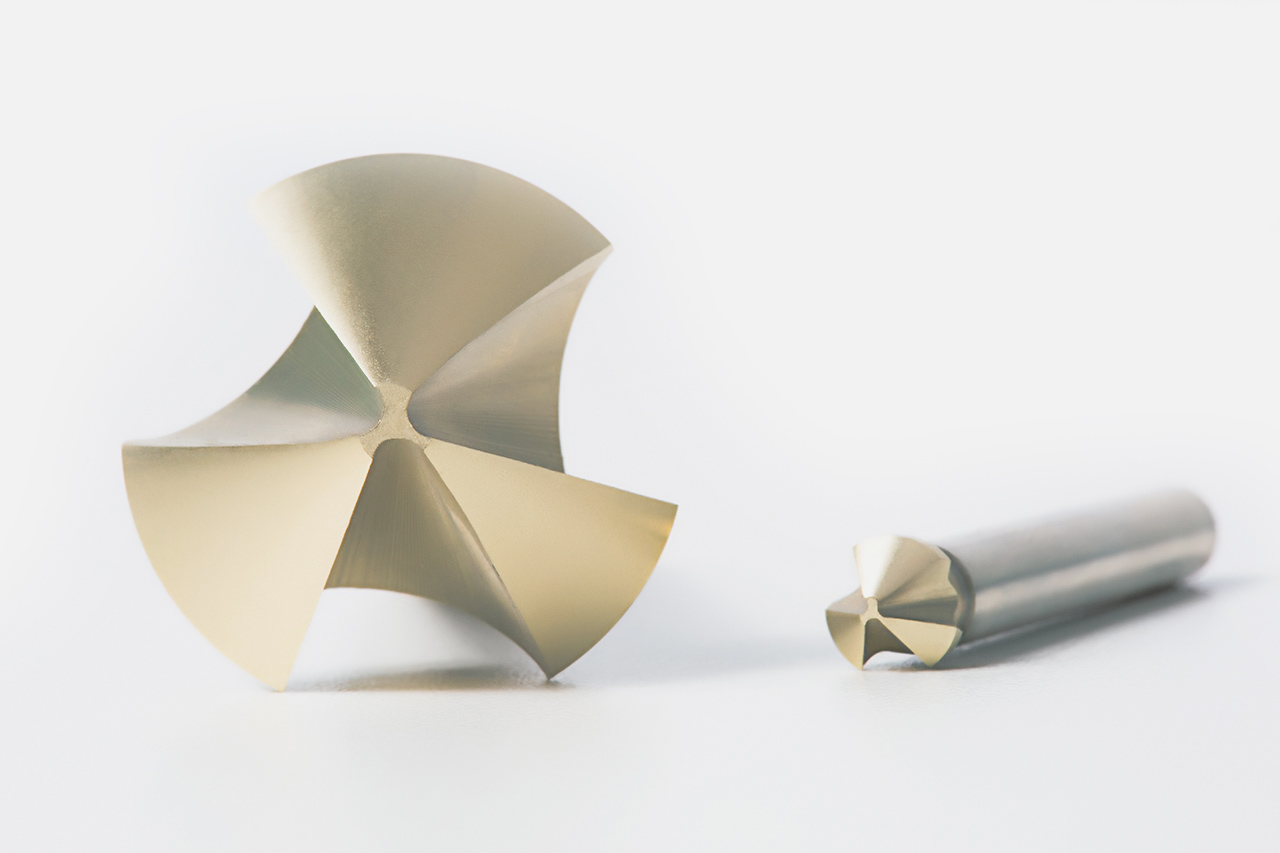

Ferramentas com insertos intercambiáveis ISO assumem um papel de liderança na área de alargamento. Baseado no know-how de usinagem fina a MAPAL desenvolveu um amplo programa padrão para este tipo de usinagem. Brocas PKD podem ser projetadas de modo ideal para soluções específicas do cliente. Modelos espiralados asseguram altíssima performance e tempos de usinagem extremamente reduzidos.

Também para usinagens secundárias – como rebaixos – a MAPAL oferece a solução ideal, seja com ferramentas projetadas especificamente para esta tarefa ou brocas combinadas com estágio de rebaixo.

Processos padronizados e inúmeras unidades do Grupo MAPAL ao redor do mundo garantem um fornecimento de ferramentas otimizado e a reafiação de ferramentas de metal duro e PKD com o mesmo nível de alta qualidade.

Ferramentas com insertos intercambiáveis ISO assumem um papel de liderança na área de alargamento. Baseado no know-how de usinagem fina a MAPAL desenvolveu um amplo programa padrão para este tipo de usinagem. Brocas PKD podem ser projetadas de modo ideal para soluções específicas do cliente. Modelos espiralados asseguram altíssima performance e tempos de usinagem extremamente reduzidos.

Também para usinagens secundárias – como rebaixos – a MAPAL oferece a solução ideal, seja com ferramentas projetadas especificamente para esta tarefa ou brocas combinadas com estágio de rebaixo.

Processos padronizados e inúmeras unidades do Grupo MAPAL ao redor do mundo garantem um fornecimento de ferramentas otimizado e a reafiação de ferramentas de metal duro e PKD com o mesmo nível de alta qualidade.