E-Mobility

-

24.09.2025

IMPULSE 85 has been published

Innovations and solutions of the year 2026 are in the focus of issue 85 of the technology magazine IMPULSE

-

12.08.2025

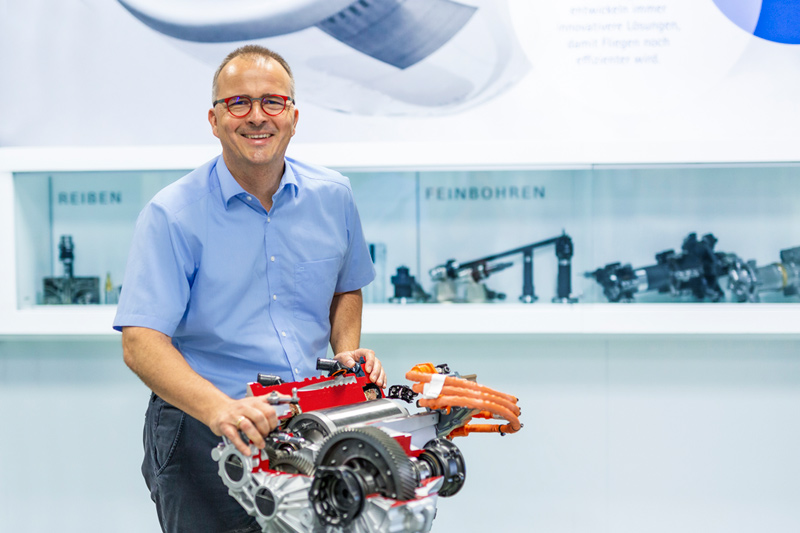

Matthias Winter on key focus areas in the automotive segment

The technological transformation driven by electrification and autonomous driving is placing new demands on the automotive segment. Matthias Winter discusses the key focus areas.

-

29.07.2025

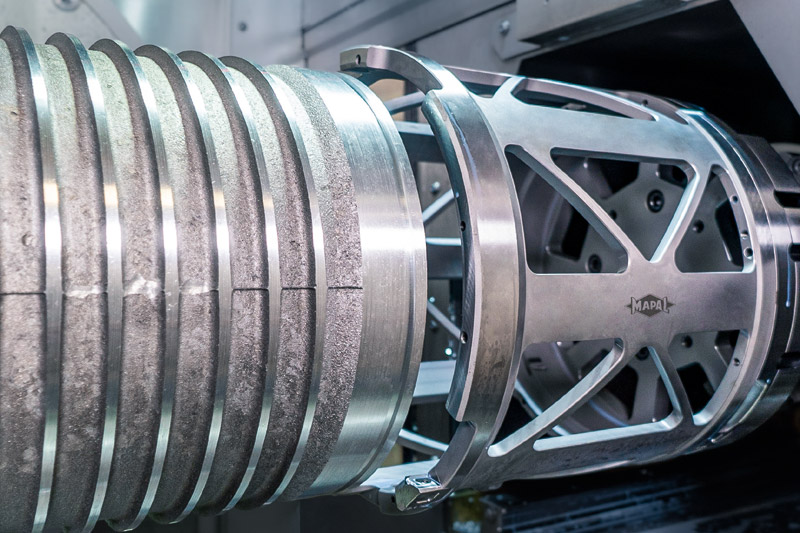

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

06.11.2024

Optimum processing through component and market expertise: solutions for the scroll compressor

Machining solutions for scroll compressors: MAPAL offers precise, durable tools for electromobility. Focus on quality, efficiency and application-orientated processes.

-

02.08.2023

Well positioned for e-mobility

The die-casting foundry 2A is ready for the transition to electric mobility. MAPAL is at 2A's side as an experienced tool partner.

-

11.05.2023

A strategy for battery frames

MAPAL’s electric mobility experts have designed a generic component that encompasses the main machining operations of a battery frame.

-

09.03.2023

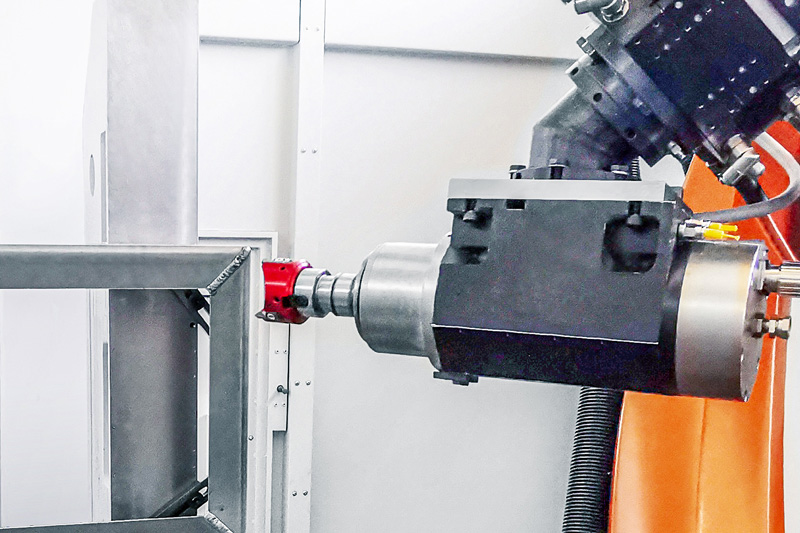

Four inserts for stator bores

Actuating tool with four facing slides and HSK100 connection for finishing the stator bore combines precision, flexibility and long tool life.

-

25.01.2023

Gnutti Carlo Group relies on c-Com digital tool management

The Gnutti Carlo Group implements a digital tool management solution from c-Com for its worldwide locations.

-

12.01.2023

Basic–Performance–Expert

MAPAL clusters its machining solutions for electromobility components into solution stages, depending on the precision requirements and production volume.

-

23.11.2022

Sights set firmly on supply chains and key components

Matthias Winter in an interview about the market development in the automotive sector, MAPAL's focus within the e-mobility sector and challenges in machining.

-

03.11.2022

Efficient deburring with robots

The FlyCutter from MAPAL is ideally suited for deburring battery trays. Robot manufacturer KADIA is enthusiastic about the PCD-tipped milling tool.

-

22.08.2022

A new turn for e-mobility

Innovative machining process from NILES-SIMMONS and MAPAL with simultaneous internal and external machining and a combination of turning and boring/fine boring.

-

11.08.2022

MAPAL at the AMB 2022

At AMB 2022 in Stuttgart, MAPAL will be presenting innovations for the focus industries and options for increasing sustainability in Hall 1, Stand D10.

-

04.10.2021

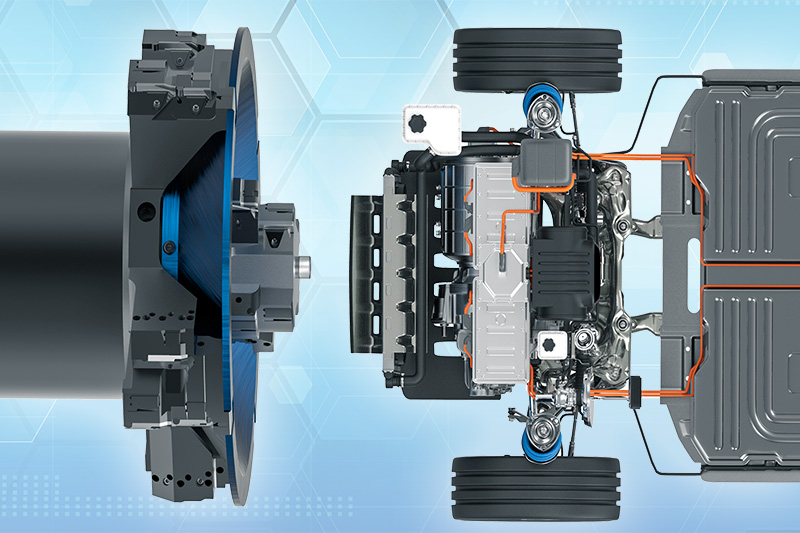

Continuous process for electromobility

Topfförmige Statorgehäuse für Elektromotoren sind aufgrund ihrer Dünnwandigkeit und engen Toleranzen anspruchsvoll zu bearbeiten. MAPAL liefert den kompletten Prozess.

-

01.04.2021

E-Mobility: New Catalogue

Electrified components, their structure, their requirements and MAPAL's machining concepts –useful tips and detailed illustrations.

-

04.12.2020

Electrified Mobility

Reliable machining of small housings for electric motors made of magnesium and aluminium

-

01.07.2019

Electric motor housings reliably enter large-scale production

For the complete machining of housings for electric motors, MAPAL is offering tool solutions which are ready for series production, reliable and absolutely precise.

-

01.01.2019

Changing Mobility

How machine manufacturer Heller together with tool manufacturer MAPAL brought the manufacturing of a newly designed stator housing to series maturity.

-

01.11.2018

Constant velocity joints for electro mobility

Why Neapco relies on ball nose milling cutters from MAPAL for hard machining the homokinetic outer joint of a drive shaft.