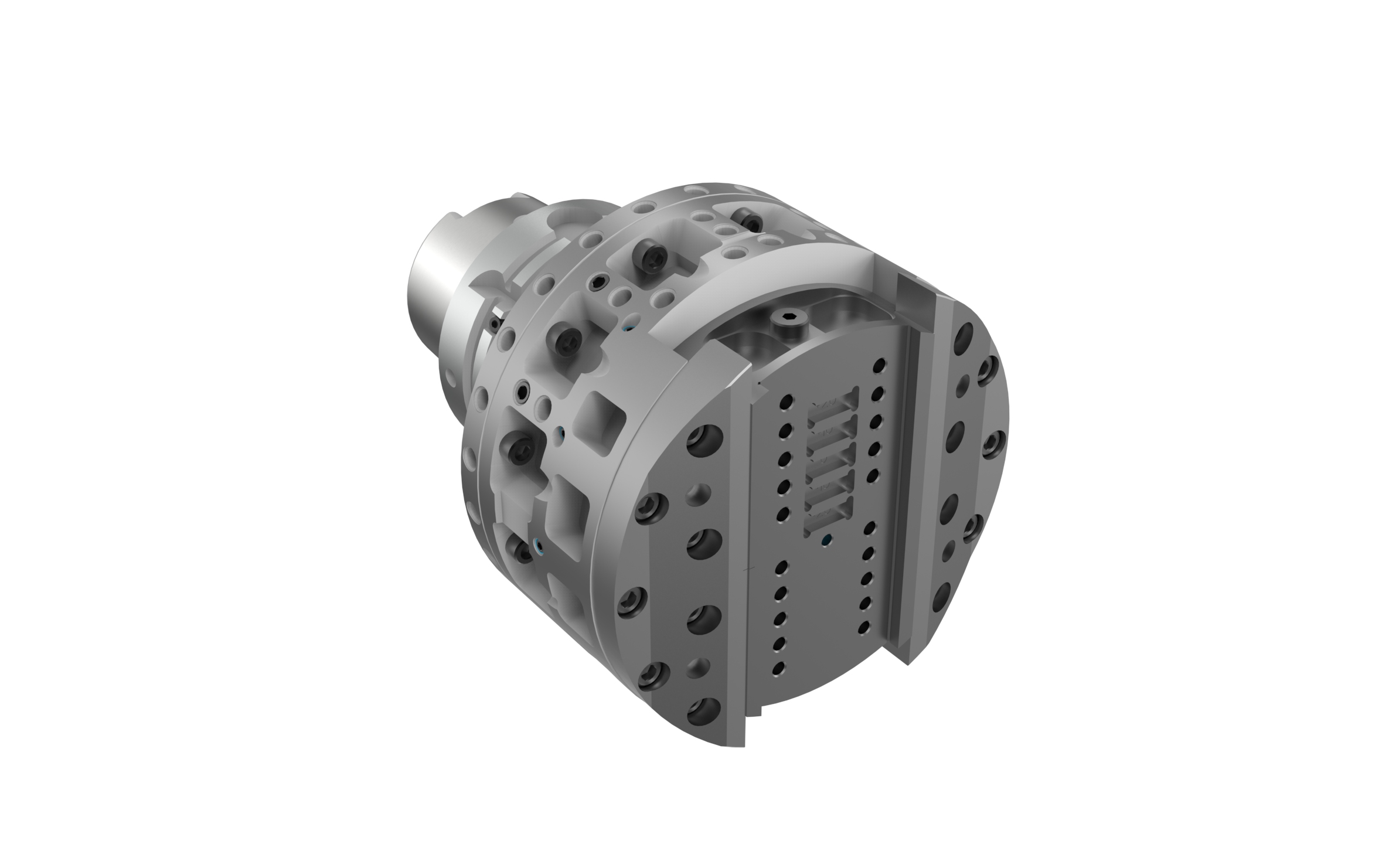

Actuator housing

Application solutions using actuating technology

Actuator housing AlSi10

Initial situation at the customer

- Requirements for complex contour machining met by a single tool system: Face, chamfer and diameter machining as well as taper machining 1:50 (1.1146°)

- High requirements regarding form and length as well as IT8 tolerances

Special features of this solution

- Internal and external machining can be handled reliably with optimal concentricity

- Automatic tool change possible

- Tool configuration does not affect machining times thanks to replacement tools

- Flexible processes mean preconfiguration is possible on a setting fixture

- It is possible to use standard tools (e.g., drills and milling cutters) in the same spindle

- Indexable insert technology for low cutting material costs

Tool highlights

- HSK-A100 with U-axis (rotating axis)

- Internal and external machining with a mounting tool

- Face stroke 56 mm

- Diameter range for machining is 112 mm

- Mounting tool can be offset in five steps for a maximum range of diameters

- Optimal cooling lubricant supply through inner coolant channel directly onto the cutting edges

.pptx - PowerPoint/2023-11-29-14-00-36-Aussteuern-Kundenpr-sentation-EN-1-.pptx-PowerPoint.jpg)

Advantages

- Complex contours and required accuracy handled by a single tool system

- Low cutting material costs in series production as only two tool types are required for all variants

- Maximum process reliability despite high variance as contours and taper shape 1:50 (1.146°) are freely programmable and can be corrected

- Technology partnership with MAPAL makes it possible to combine all machining steps