11.05.2023

A strategy for battery frames

The complete machining of parts has to be well thought out, every step coordinated with the next. This is the only way to attain reliable and cost-effective manufacturing with perfect results. To provide customers with such sophisticated strategies, MAPAL has defined focus components on electric cars and worked out the optimal machining strategy for them. The battery frame is one of these components.

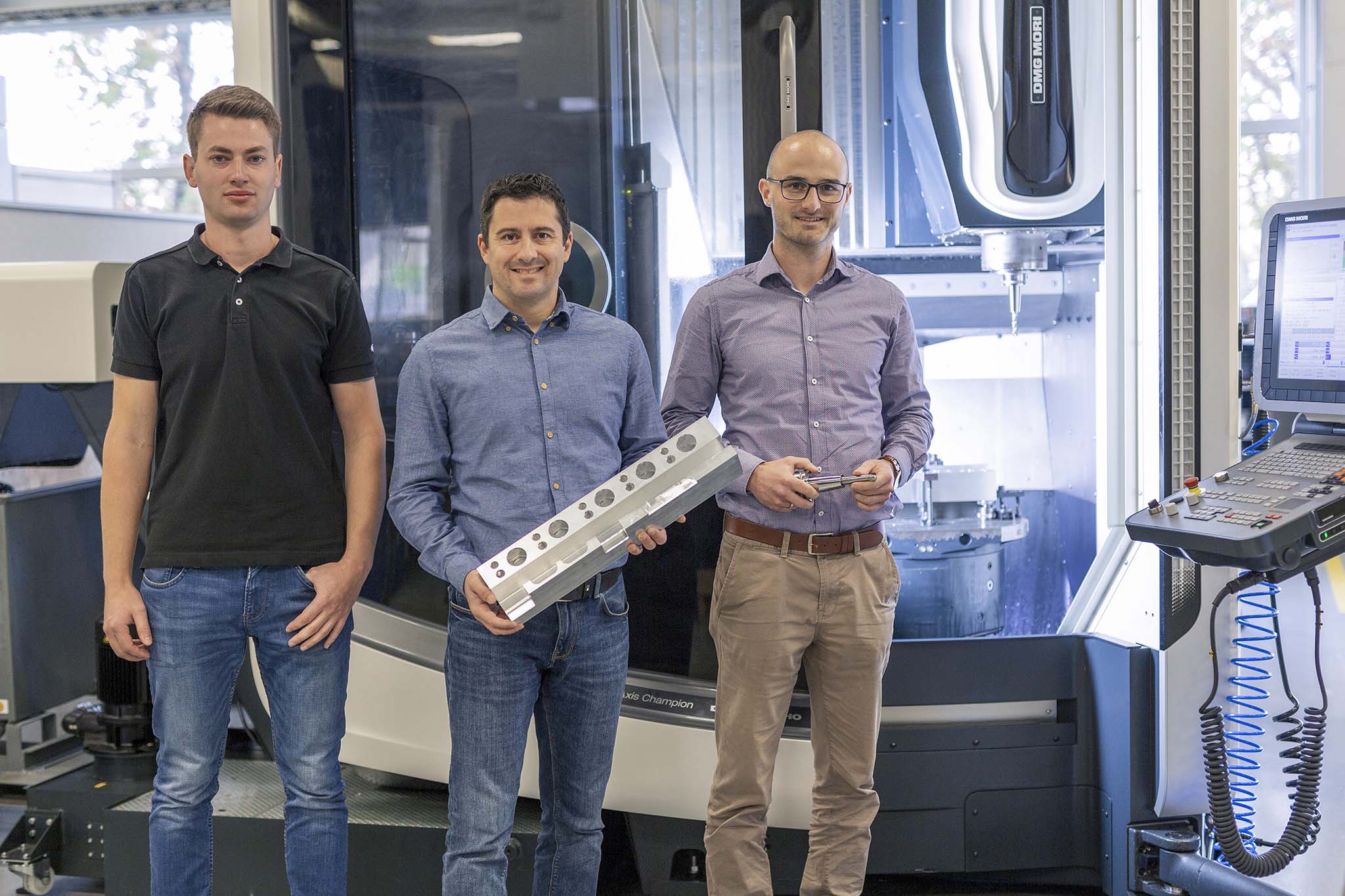

The battery frame is a crucial part in every electric car. It usually consists of various frame elements that are welded together after pre-machining and act as the battery’s enclosure. Based on various customer parts, MAPAL’s electric mobility experts have put together a generic component that encompasses the main machining operations of a battery frame. “With this part, we highlight the special challenges involved in machining”, says Michael Kucher, Component Manager E-Mobility at MAPAL.

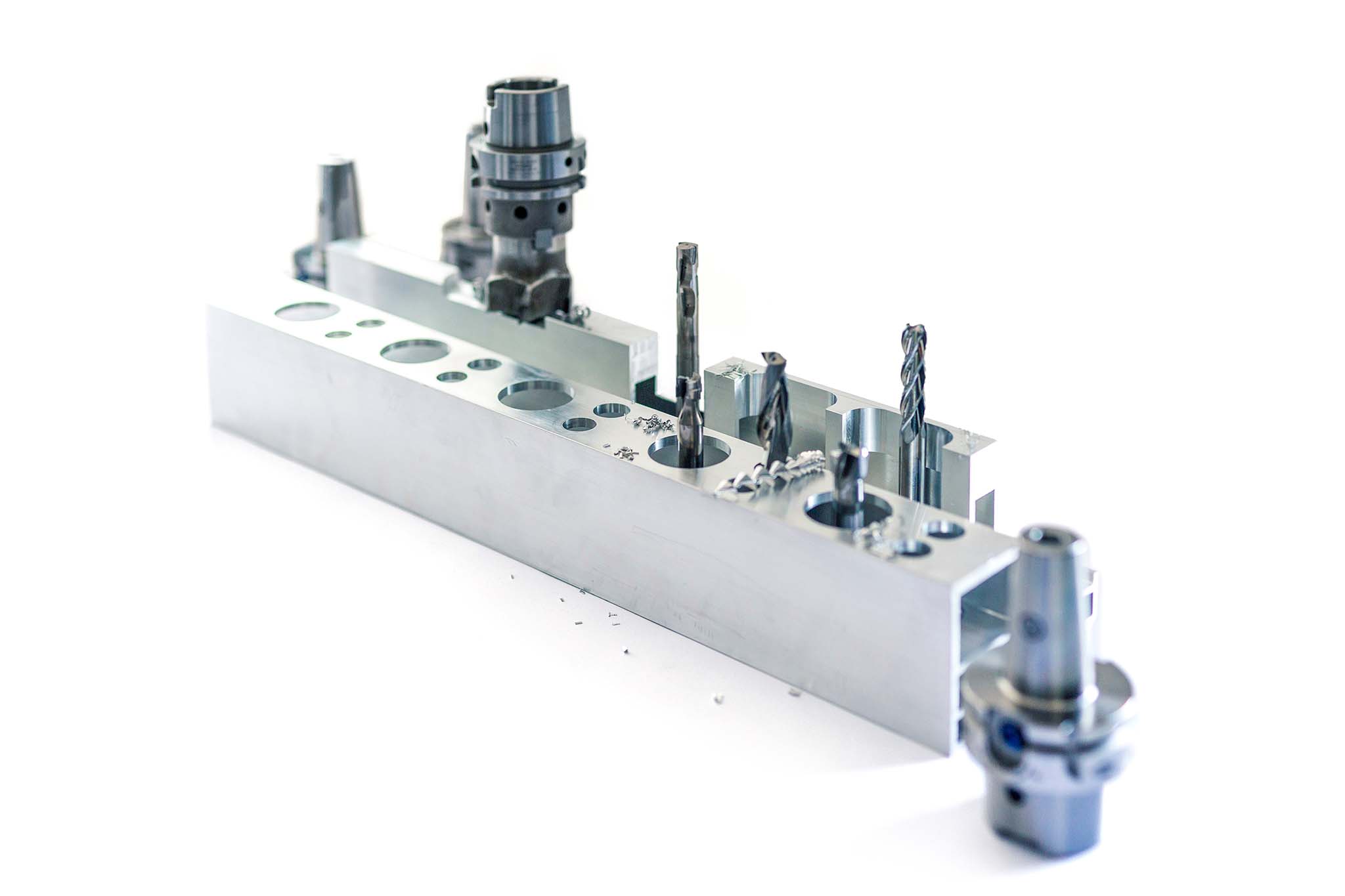

The challenges faced while machining the part include stepped bores, bores with different diameters through multiple layers, milled pockets with varying dimensions, shoulders, and high demands on the resulting surface.

This advantage is brought to bear particularly when a bore has a larger diameter in one of the lower layers than the bore entrance at the top layer. “This can be done effectively with a reverse cutting edge on the milling cutter”, says Kucher. The alternative would be reclamping the workpiece in order to machine the bore from the bottom with a drill. A specially designed PCD milling cutter from MAPAL machines the bore at a spindle speed of 16,000 rpm, a cutting speed of 650 m/min and a feed of 0.063 mm.

Optimal surfaces with the OptiMill-SPM-Finish

MAPAL recommends the OptiMill-SPM-Finish for roughing shoulders, pockets and slots as well as finishing pockets. “It achieves an optimal surface finish and works stably even in corners with large wrapping and high loads”, Kucher says of the tool. Because the chip spaces are polished, chip removal functions perfectly. The special feature of this tool is that the user can finish large depths in a single pass. This saves time, making it particularly cost-effective. When finishing the battery frame, a surface finish of up to Rz = 1 µm is achieved. During roughing, it operates at a spindle speed of 10,981 rpm, a cutting speed of 414 m/min and feed rates between 0.12 and 0.22 mm. The same spindle and cutting speeds are achieved during finishing with a feed of 0.075 mm.

In total, seven tools are used during the generic process, including six milling cutters: besides the OptiMill-SPM-Finish, amongst others the recently introduced FaceMill-Diamond-ES. In order to attain a perfectly harmonised system, all of the tools with cylindrical shanks are clamped in the new UNIQ chucks in the generic process.

“We can now offer our clients an all-round package to meet the challenges of machining battery frames, which includes PCD and solid carbide tools, chucks, and the corresponding process. For this we adapt the generic process for our customers based on their concrete situation”, Kucher explains.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342