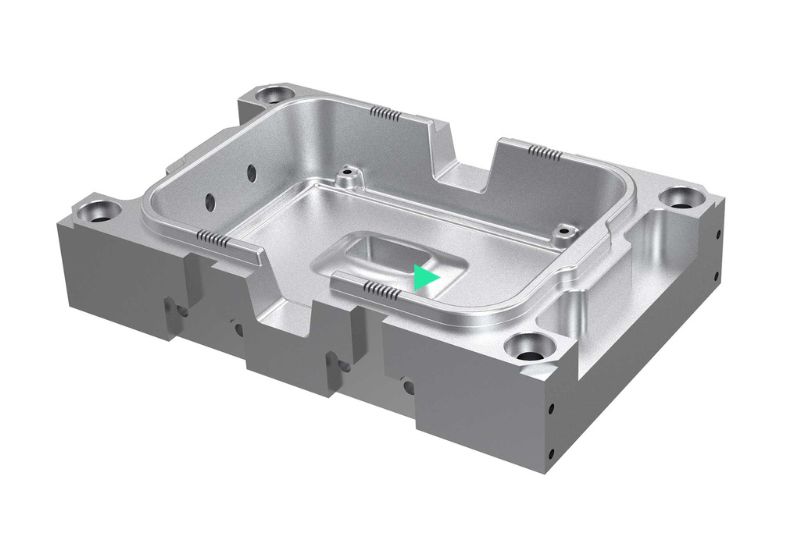

Bearbeitung von 3D-Flächen

Im Werkzeug- und Formenbau ist die Herstellung komplexer werdender Formen Alltag. Kontinuierliche Weiterentwicklungen bei Werkzeugmaschinen und CAM-Software heben die Leistungsfähigkeit und Produktivität auf ein immer höheres Niveau. Somit müssen auch die eingesetzten Werkzeuge stets dem neuesten Stand der Technik entsprechen. Um hier ein Optimum zu erreichen, steht eine Prozessanalyse am Beginn der Auslegung.

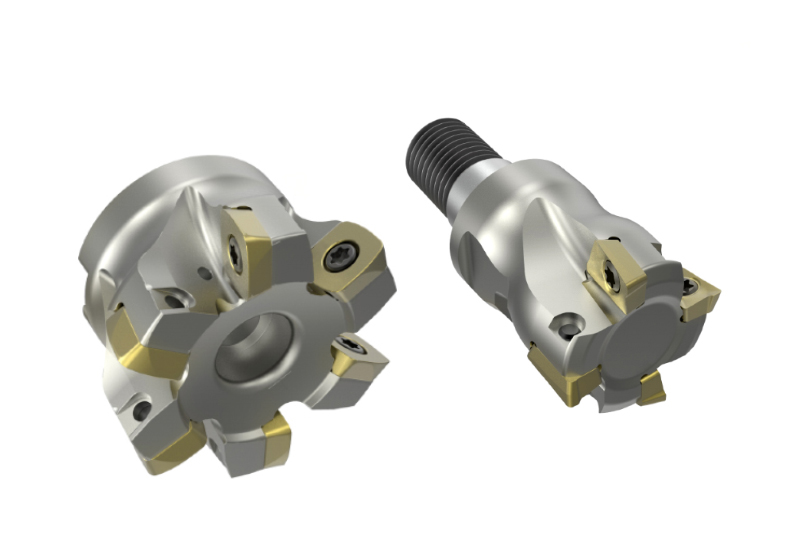

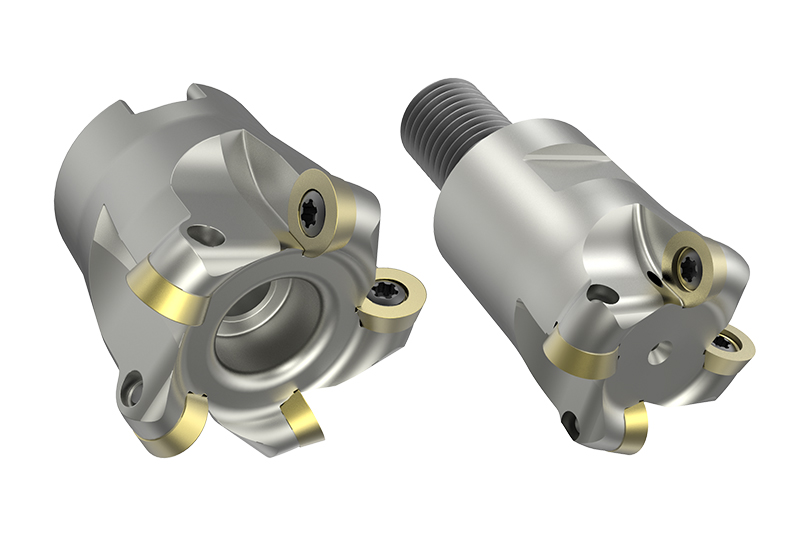

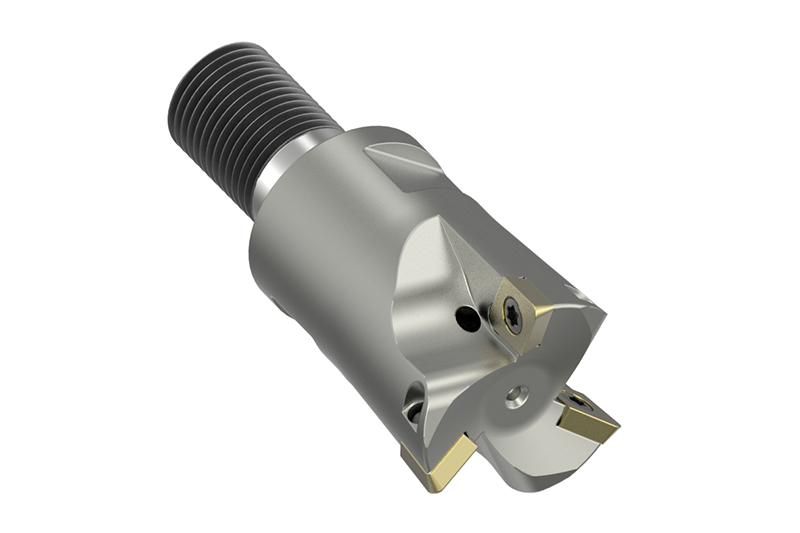

Werkzeugübersicht für folgende Bearbeitungsschritte:

Schruppen

Die Schruppoperation ist für den Großteil des Zerspanungsvolumens verantwortlich. Spezielle Frässtrategien wie die Hochvorschubbearbeitung oder das trochoide Fräsen können die Bearbeitungszeit reduzieren und somit die Wirtschaftlichkeit steigern. Neben Werkzeugen mit Wendeschneidplatten und Vollhartmetallfräsern kommen Hochleistungsfräser mit spezieller Schruppgeometrie zum Einsatz.

Restmaterial schruppen

Nach dem Schruppen bearbeiten Anwender in einem zweiten Bearbeitungsschritt das Restmaterial, insbesondere in Ecken und Kavitäten, auf ein möglichst konstantes Aufmaß vor. In der Regel kommen Werkzeuge mit Eckenradius oder Hochvorschubfräser zum Einsatz. Bei Bedarf kann auch ein Kugelfräser das Restmaterial in Ecken entfernen.

Vorschlichten

Bei hohen Anforderungen an Maßhaltigkeit und Oberflächengüte empfiehlt sich vor dem Schlichten eine Semi-Schlichtbearbeitung. Mit dem Vorschlichten nähert sich die Bearbeitung dem endgültigen Formprofil an. Ziel ist es, ein möglichst konstantes Restmaterial zu erhalten, um ein schnelles Schlichten mit hohen Anforderungen an die Oberflächenqualität zu ermöglichen. Das Aufmaß nach dem Schruppen beträgt ca. 0,5-1 mm bei gehärteten Materialien und 0,03-0,5 mm bei weichen Materialien. Nach dem Vorschlichten betragen die konstanten Aufmaße 0,05-0,1 mm bei gehärteten Materialien beziehungsweise 0,1-0,3 mm bei weichen Materialien.

Schlichten

Die Schlichtbearbeitung trägt das verbleibende Aufmaß ab, um die finale Form zu erreichen. Nach der Vorschlichtbearbeitung beträgt dies 0,05-0,1 mm bei gehärteten Materialien beziehungsweise 0,1-0,3 mm bei weichen Materialien. Kugel- und/oder Eckradiusfräser sind das Mittel der Wahl, abhängig von den finalen Konturen des Werkstücks.

Restmaterial schlichten

Die immer komplexeren Eigenschaften der herzustellenden Formen erfordern nach der Schlichtbearbeitung ein Fräsen des Restmaterials, hauptsächlich in den Ecken. Hierfür kommen in der Regel Kugelfräser aus Vollhartmetall zum Einsatz.