Hydraulik Steuerblock

Hydraulik Steuerblock 9SMn28k / EN-AW6082

Ausgangssituation beim Kunden

- Einzelaufträge, kleinere und mittlere Stückzahlen

- Hohe Bauteil- und Werkstoffvarianz

- Geringe Durchlaufzeit

- Hohe Qualitätsansprüche an Oberfläche und Gratarmut

Besonderheiten der Lösung

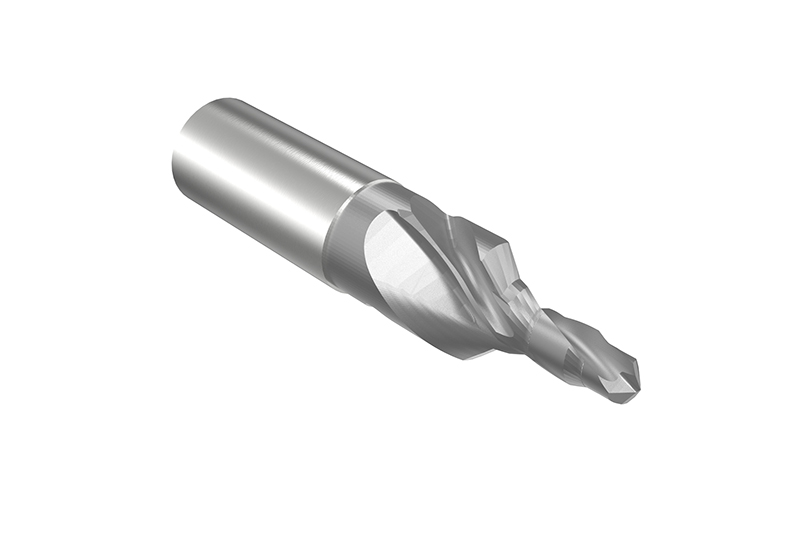

- Verschiedene Werkstoffe können mit nur einem Werkzeuggrundkörper bearbeitet werden

→ Wendeplattenlösungen ermöglichen maximale Flexibilität bei kleinen Loßgrößen - Vermeidung von Werkzeugbrüchen beim Herstellen von überschneidenden Ölkanalbohrungen

- Sichere Spankontrolle bei der Bearbeitung von langspanenden Materialien

- Effiziente Stufenwerkzeuge → Prozesssichere Herstellung von Form & Lagetoleranzen

Ventilbohrung

Ölbohrung

Vorteile

- Ideale Prozessabfolge gewährleistet höchste Produktivität und geringe Durchlaufzeiten

- Kombinationswerkzeuge egalisieren den Einsatz von weiteren Werkzeugen bei hoher Bauteil- und Werkstoffvarianz und limitierten Werkzeugplätzen

- Bauteilübergreifende Mehrfachverwendung der Werkzeuglösungen für Ventil,- und Anschlussbohrungen

- Breites Standardportfolio gewährleistet einfache und schnelle Bearbeitungen bei Kleinserien und Prototypenbau

![BEARBEITUNGSZEIT PRO VENTILBOHRUNG [SEK.]](/medias/sys_master/root/h75/h1e/9175132962846/Grafiken__DE3/Grafiken-DE3.jpg)