01.06.2018

Ratterfreier Prozess mit Werkzeugen von MAPAL

An die Situation angepasste Lösungen reduzieren Schwingungen deutlich

Schwingungen sind Alltag in der zerspanenden Bearbeitung und haben zwei Ursachen: Entweder werden sie von außen angeregt, oder aber der Zerspanungsprozess selbst löst sie aus. Diese selbsterregten Ratterschwingungen wirken sich negativ auf die Bearbeitung aus und können durchaus mittels geeigneter Maßnahmen beeinflusst werden. MAPAL stellt diesem Phänomen unterschiedliche Werkzeugkonzepte entgegen.

Sogenannte selbsterregte Ratterschwingungen, also von der Zerspanung selbst ausgelöste Schwingungen, wirken in mehrerlei Hinsicht negativ. An erster Stelle steht das Bearbeitungsergebnis, das der Zerspaner nicht oder nicht optimal erreicht. Schwingungen verkürzen darüber hinaus die Standzeit der Werkzeuge, oft erheblich. Zudem belastet ein Rattern die Werkzeugmaschine selbst.

Am Werkzeug nehmen die Folgen von Biege- oder Torsionsschwingungen während der Zerspanung unterschiedliche Ausmaße an, denn sie führen zum sogenannten Rattern:

- Schlechte Rundheiten und Zylinderformen

- Ungenügende Oberflächengüten

- Im Extremfall gebrochene Schneiden oder Werkzeuge.

Ursachen für Ratterschwingungen

Ratterschwingungen gehen auf eine dynamische Instabilität des Zerspanungsprozesses zurück und haben verschiedene Ursachen. Ein falsch eingespanntes Werkstück beziehungsweise eine nicht ausreichend fixierende Spannung führen ebenso zu Rattern wie ein langes, schlankes Werkzeug mit ungenügender Biegesteifigkeit. Wirkt auf ein solches Werkzeug zu viel Kraft, beispielsweise durch zu hohe Schnittgeschwindigkeiten, sind Ratterschwingungen die Folge. Eine weitere Ursache stellen sehr harte Materialien dar, die während der Bearbeitung im Vergleich zu weicheren Werkstoffen eine größere Rattertendenz aufweisen. Auch die Werkzeugspannung, generell große Schnitttiefen und unterbrochene Schnitte beeinflussen die Steifigkeit des Gesamtsystems und die Ratterneigung.

Mit den genannten Ursachen hat sich der Präzisionswerkzeughersteller MAPAL intensiv auseinandergesetzt und verschiedene Ansätze definiert, um Ratterschwingungen zu kompensieren beziehungsweise zu vermeiden: Generell verringern angepasste Schnittgeschwindigkeiten und ein optimales Verhältnis von Drehzahl zu Vorschub die Belastung und die Dynamik des Systems. Auch sehr stabil ausgeführte Werkzeuge reduzieren die wirkenden Kräfte. Spezielle Werkzeuggeometrien stabilisieren den Bearbeitungsprozess überdies.

Kegelsenker mit reduzierten Axialkräften für stabile Senkbearbeitungen

Hohe Laufruhe mit Bogenschliff bei Aufbohrwerkzeugen

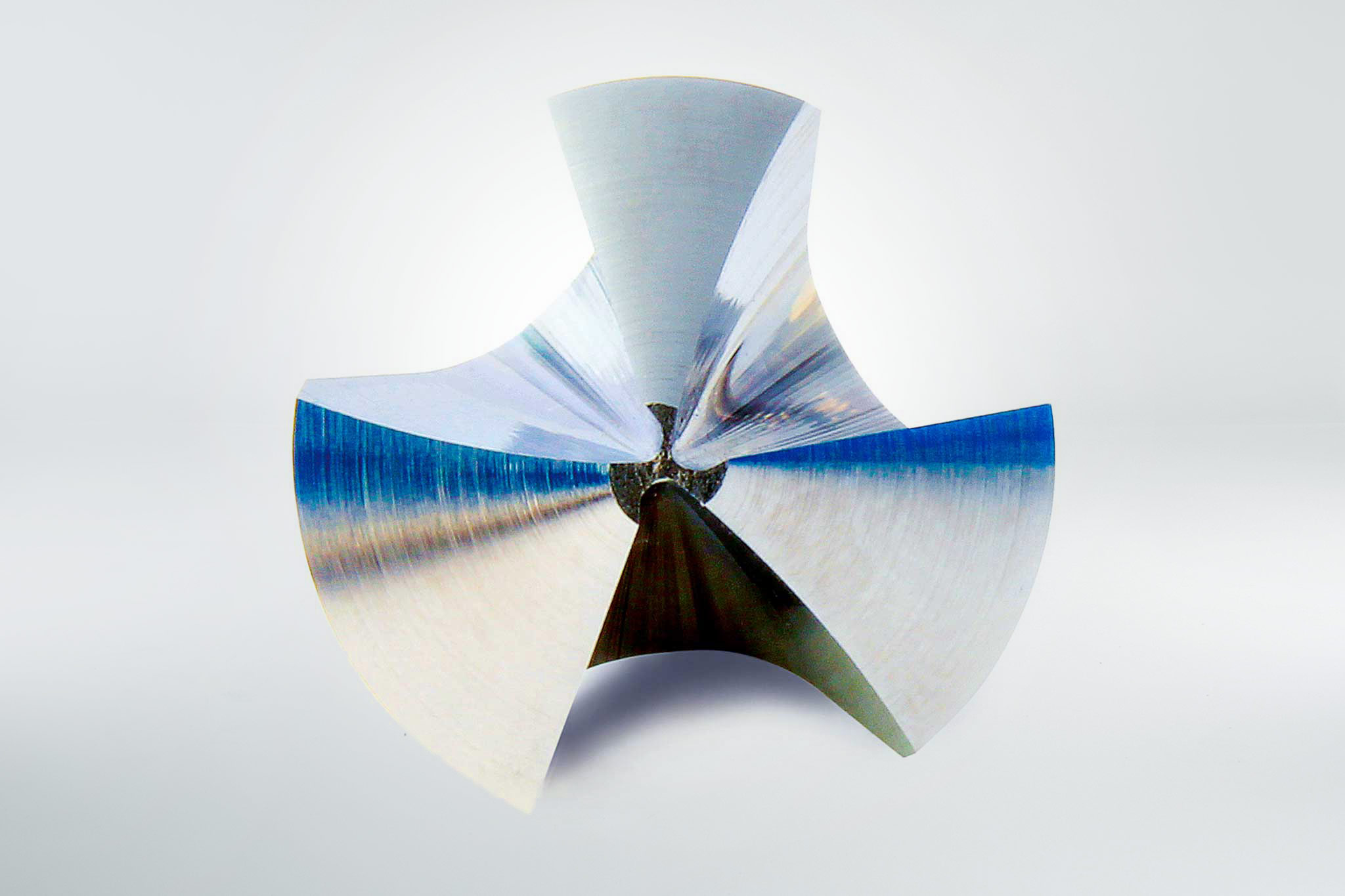

Welded construction for dynamic lightness

be absorbed or compensated. Otherwise work must be performed with such low cutting speeds

that the process is not economical. For this case, MAPAL has developed the so-called “welded construction”. A thin-walled tube serves as a tool body, making the tool extremely light but also

very stable and rigid – “dynamically light”. The carriers for the inserts and guide pads are welded on and supported one another by means of connecting ribs. To optimise the relationship of rigidity and weight and to counteract the pendulum oscillations, for this type of tool MAPAL simulates the machining forces as well as the stresses that arise, bending vibrations and torsion vibrations by means of FEM (Finite Element Method). All in all the risk of chattering is minimised and the support and therefore the stability of the entire system is also ensured for an interrupted cut.

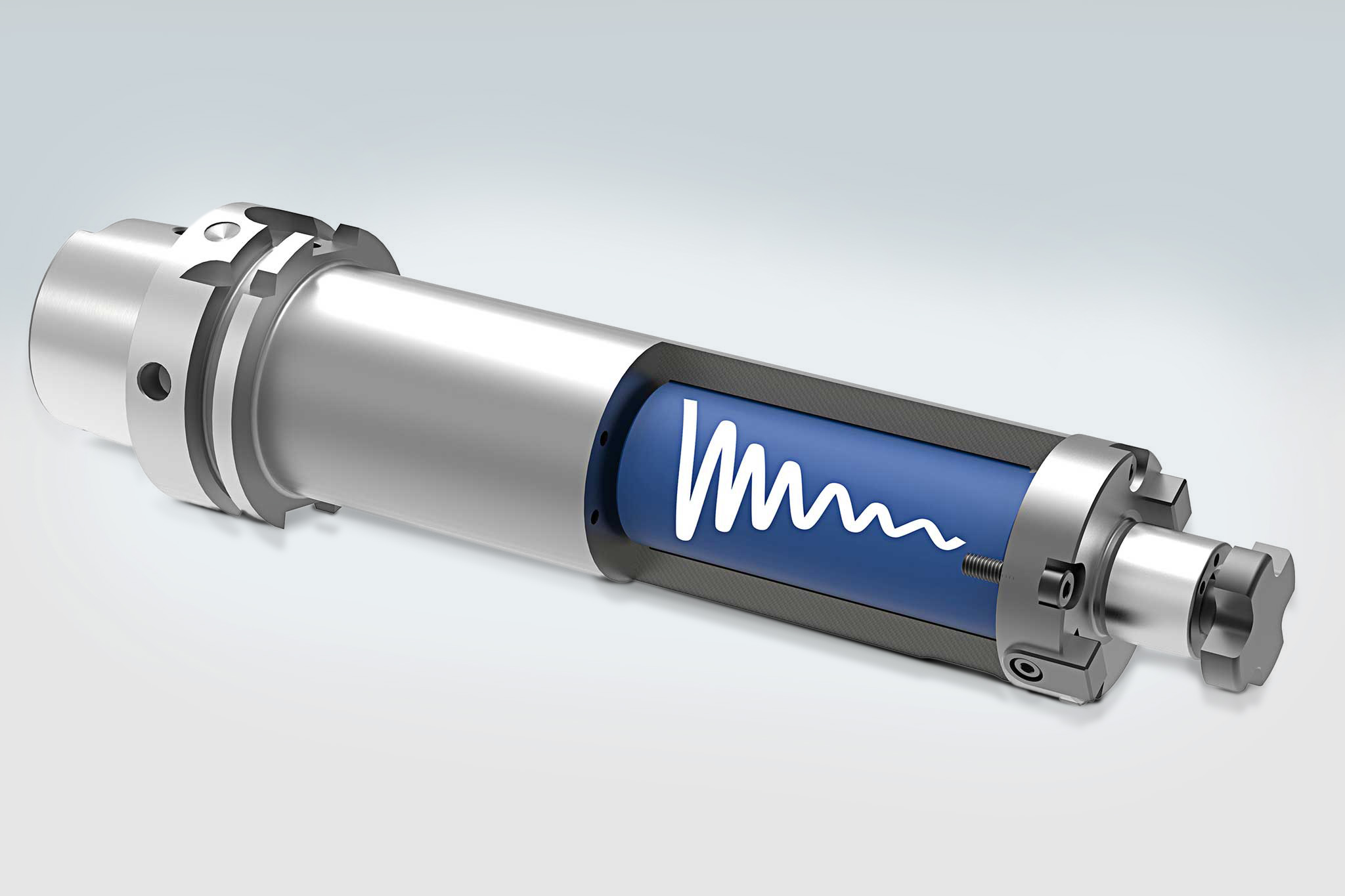

Absorder system for vibration damping in the shaft