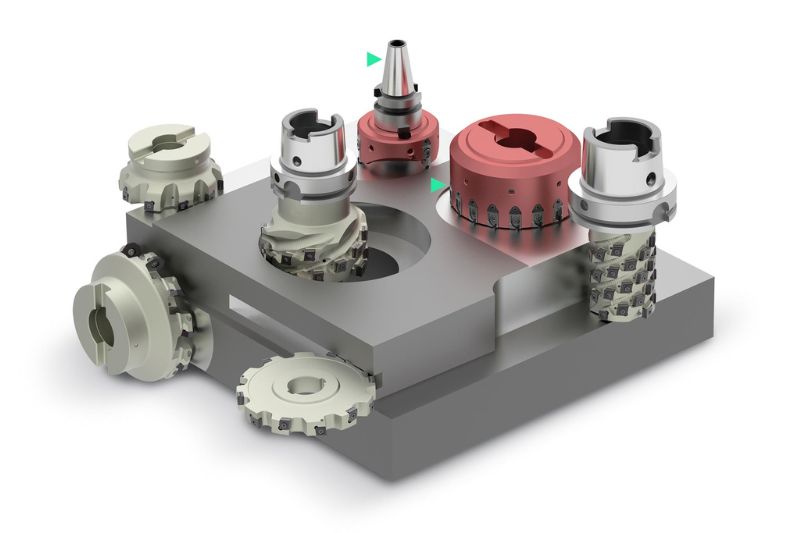

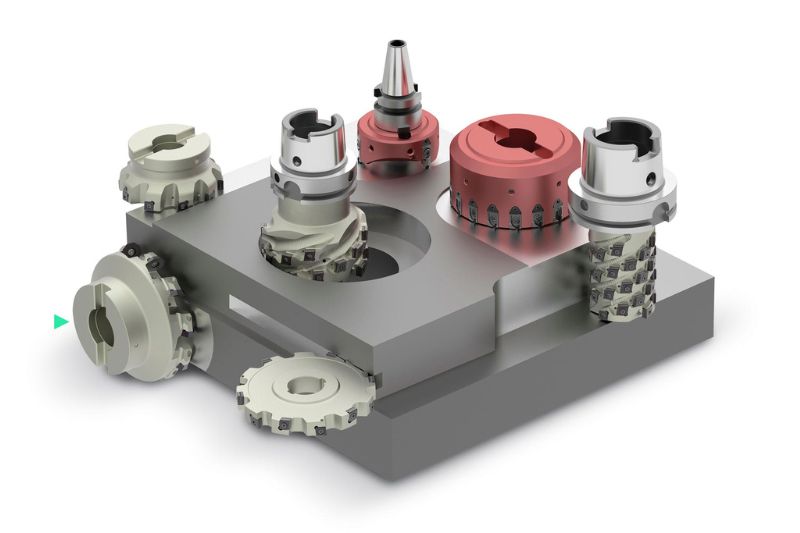

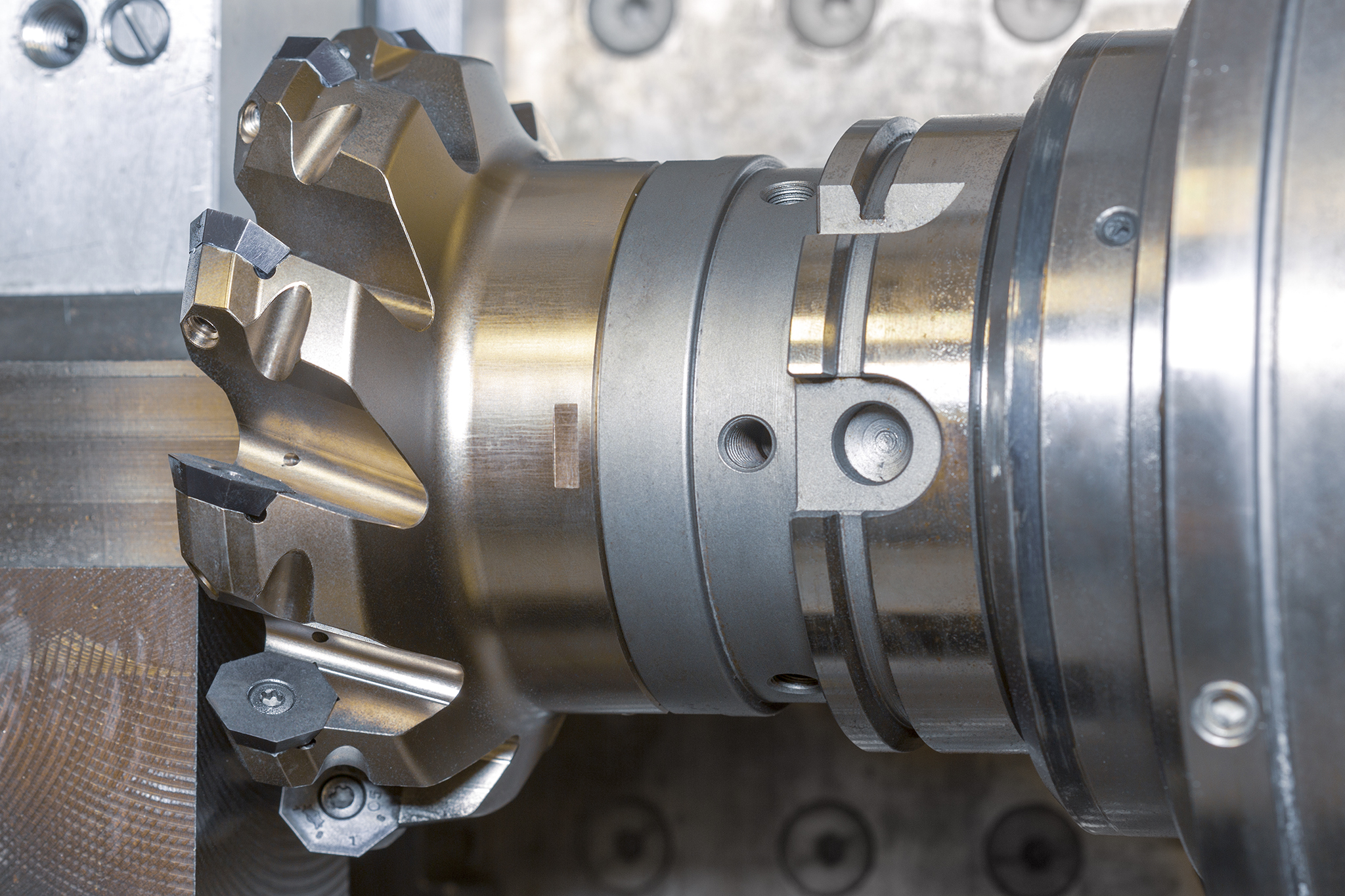

Fresas com arestas de corte substituíveis

Altíssimo desempenho na usinagem de alumínio, aço e ferro fundido

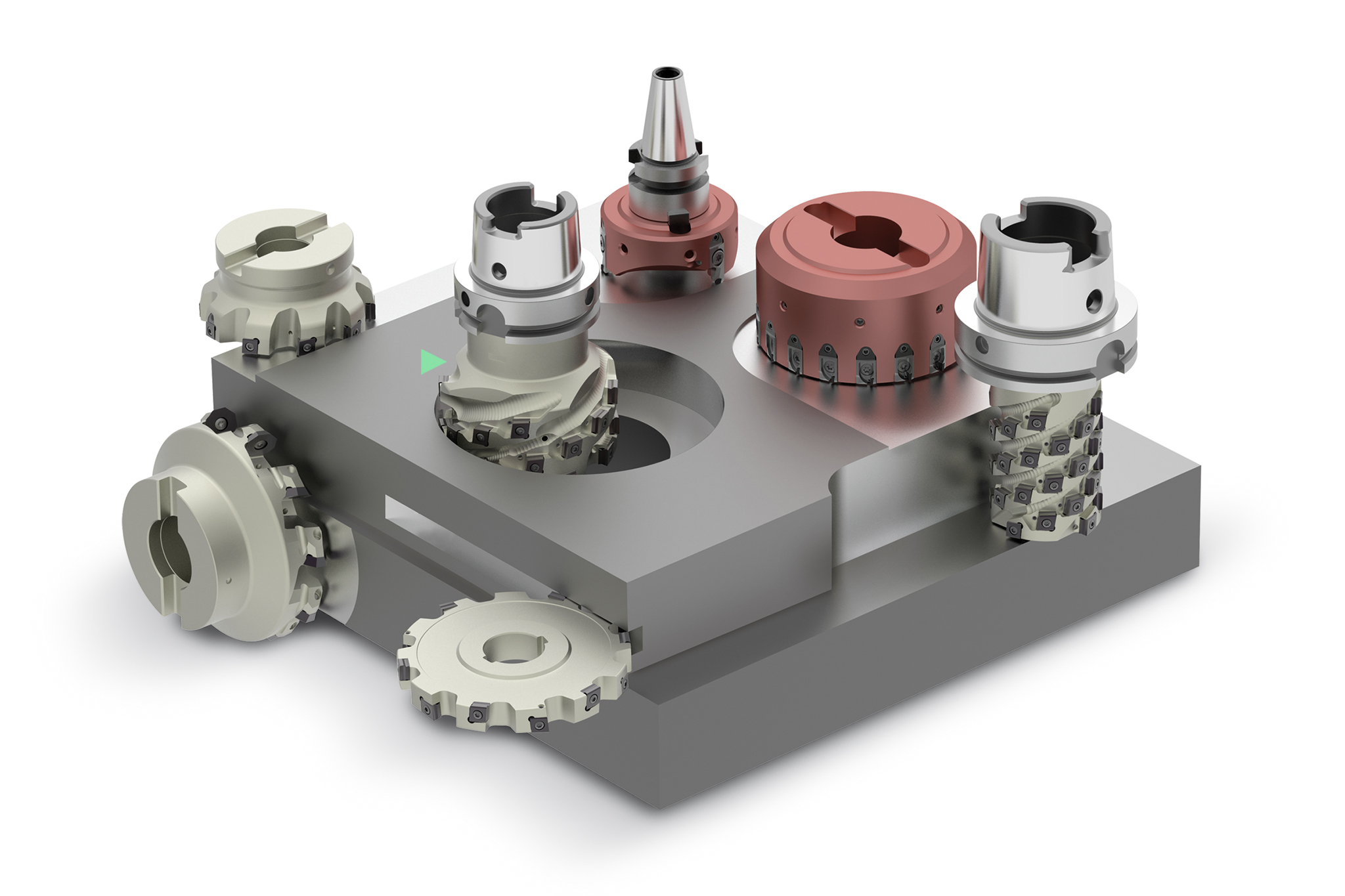

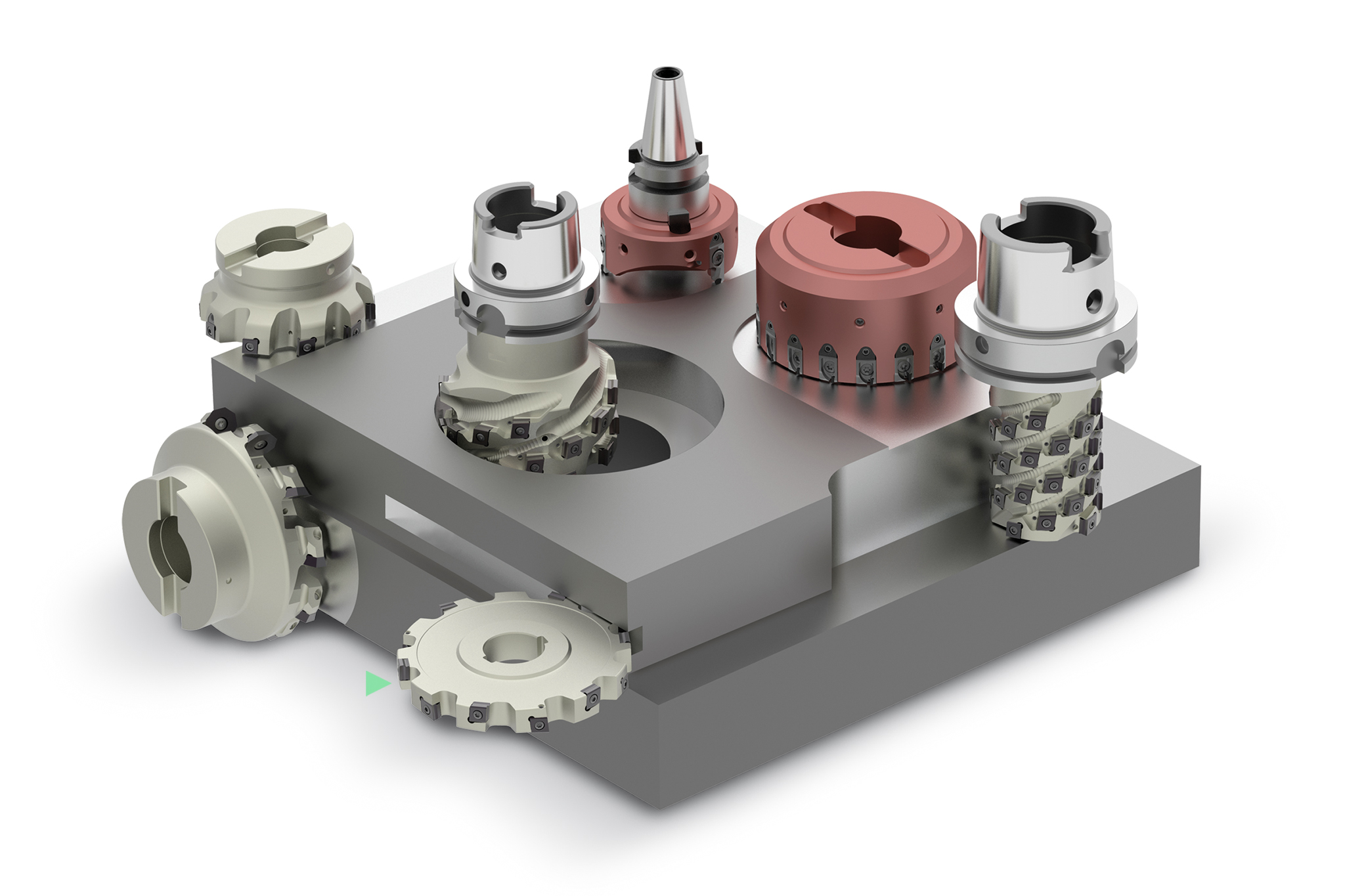

Fresas planas com insertos de fresagem PCD

Ideal para realizar altíssimas qualidades de superfície em peças de alumínio.

- Realização de superfícies com Rz ≤ 5 μm

- Faixa de diâmetro de 32 a 500 mm

- Inovadora geometria do condutor de aparas para elevada segurança de processo

- Ajuste cônico com precisão micrométrica para qualidades de superfície perfeitas

- Fresas HSC leves para máquinascom potência do fuso limitada

- Fresas com arestas de corte soldadas para profundidades de corte de até 8 mm

Fresas planas com insertos intercambiáveis

Desbaste e semi-usinagem de superfícies planas.

- Profundidades de corte de até 10 mm

- Faixa de diâmetro de 63 a 200 mm

- Possibilidade de montagem alternada de insertos intercambiáveis LTHU

- Insertos intercambiáveis com quatro ou oito arestas de corte

- Ângulo de posicionamento de 45° e 75°

Fresa de esquadrejamento

Ideal para a fresagem de superfícies de ressalto 90°.

- Profundidades de corte de até 14 mm

- Faixa de diâmetro de 16 a 200 mm

- Séries para penetração oblíqua, fresagem total de canal e fresagem de penetração

- Possibilidade de montagem alternada de insertos intercambiáveis LTHU

- Insertos intercambiáveis com quatro ou oito arestas de corte

- Ajuste axial para altíssima qualidade de superfície

- Ângulo de posicionamento de 88 ° e 90 °

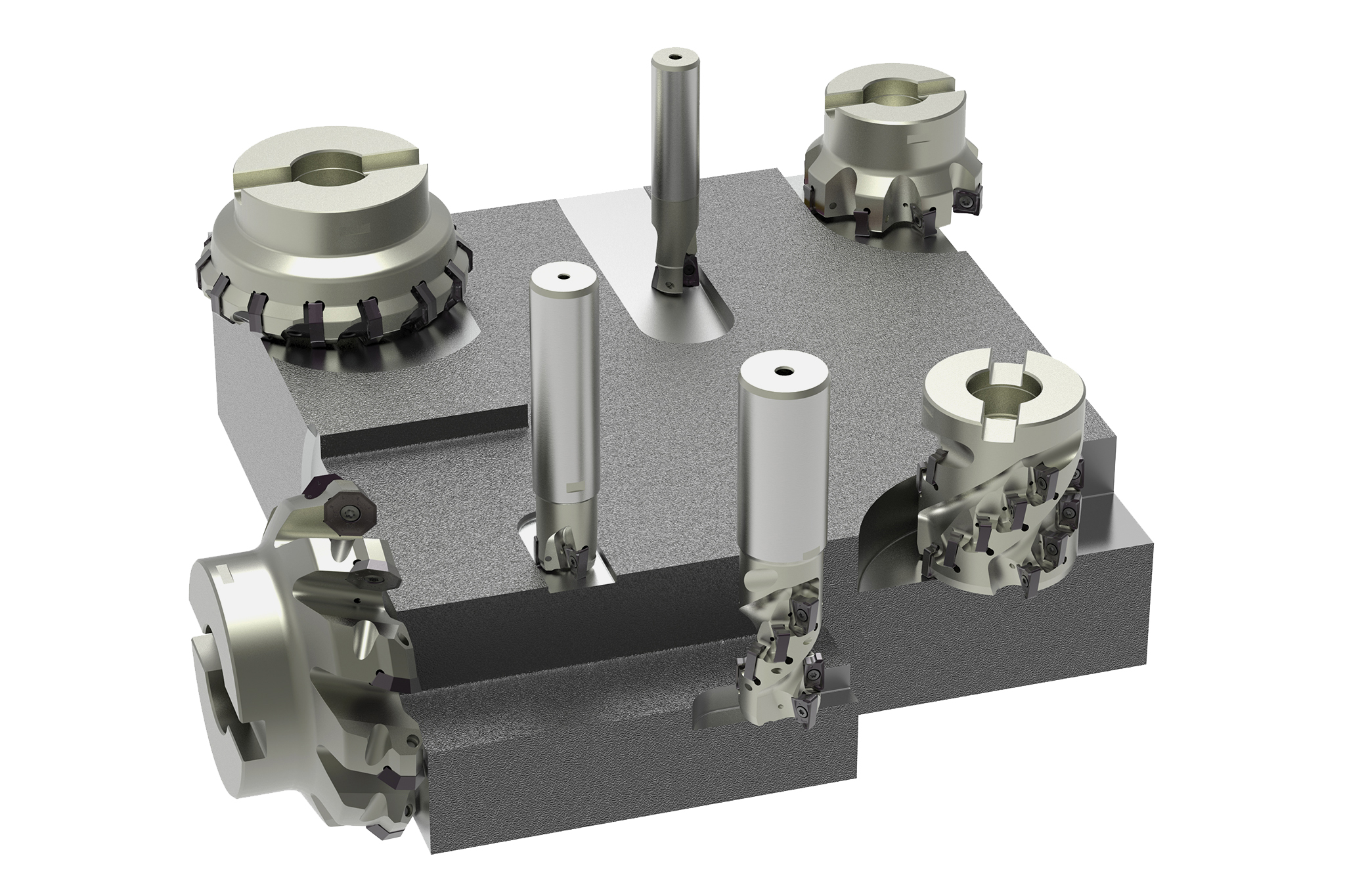

Fresas frontais de cilindros

Para a usinagem de desbaste com grandes profundidades de corte. Ideal para fresagem de esquadrejamento profunda e rebordear.

- Profundidades de corte de até 75 mm

- Faixa de diâmetro de 25 a 200 mm

- Também adequada para usinagem pesada e fresagem total de canal

- Ângulo de posicionamento 90 °

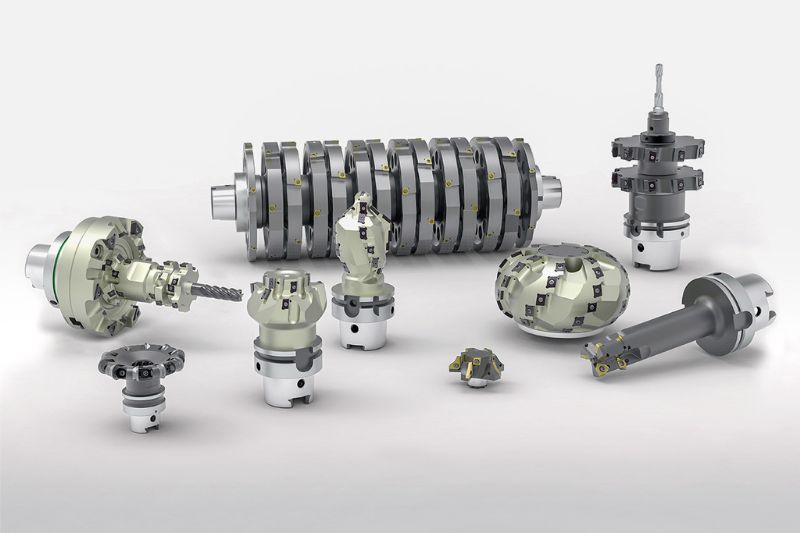

Fresas helicoidais

Para a usinagem de desbaste de grandes diâmetros de perfuração (> 150 mm).

- Profundidades de corte de até 35 mm

- Faixa de diâmetro de 80 a 160 mm

- Possibilidade de penetração e Ramping

- Amortecedor de vibrações opcional

- Ideal para centros de usinagem

- Ângulo de posicionamento 90 °

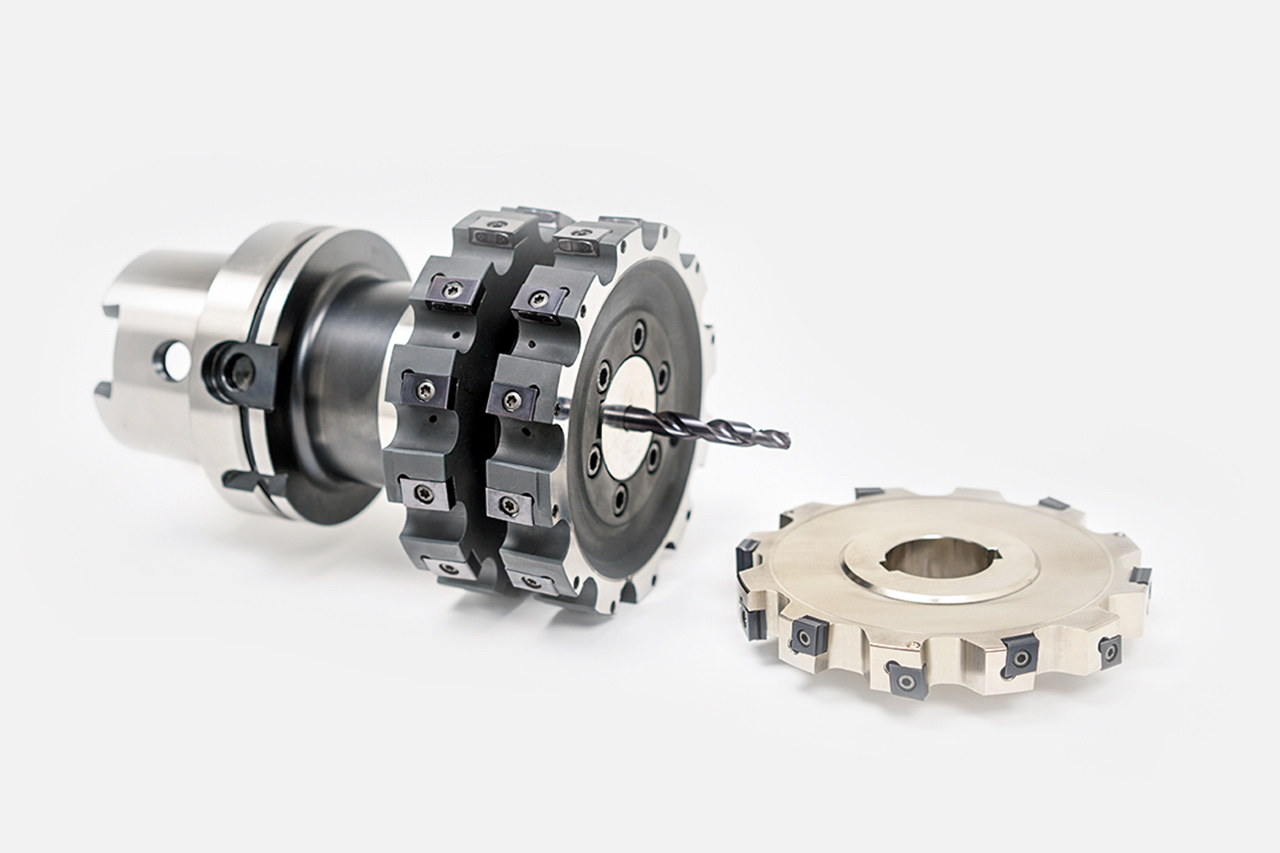

Fresas de disco

Fresagem de superfícies de ressalto profundas ou canais. Pode ser utilizada como fresa conjugada ou eixo de fresagem.

- Profundidades de corte de até 17 mm

- Faixa de diâmetro de 100 a 200 mm

- Ideal para máquinas-ferramenta com mandril de contra-ponto extensível

- Ajustável axialmene paa usinagem de acabamento

- Ângulo de posicionamento de 88 ° e 90 °

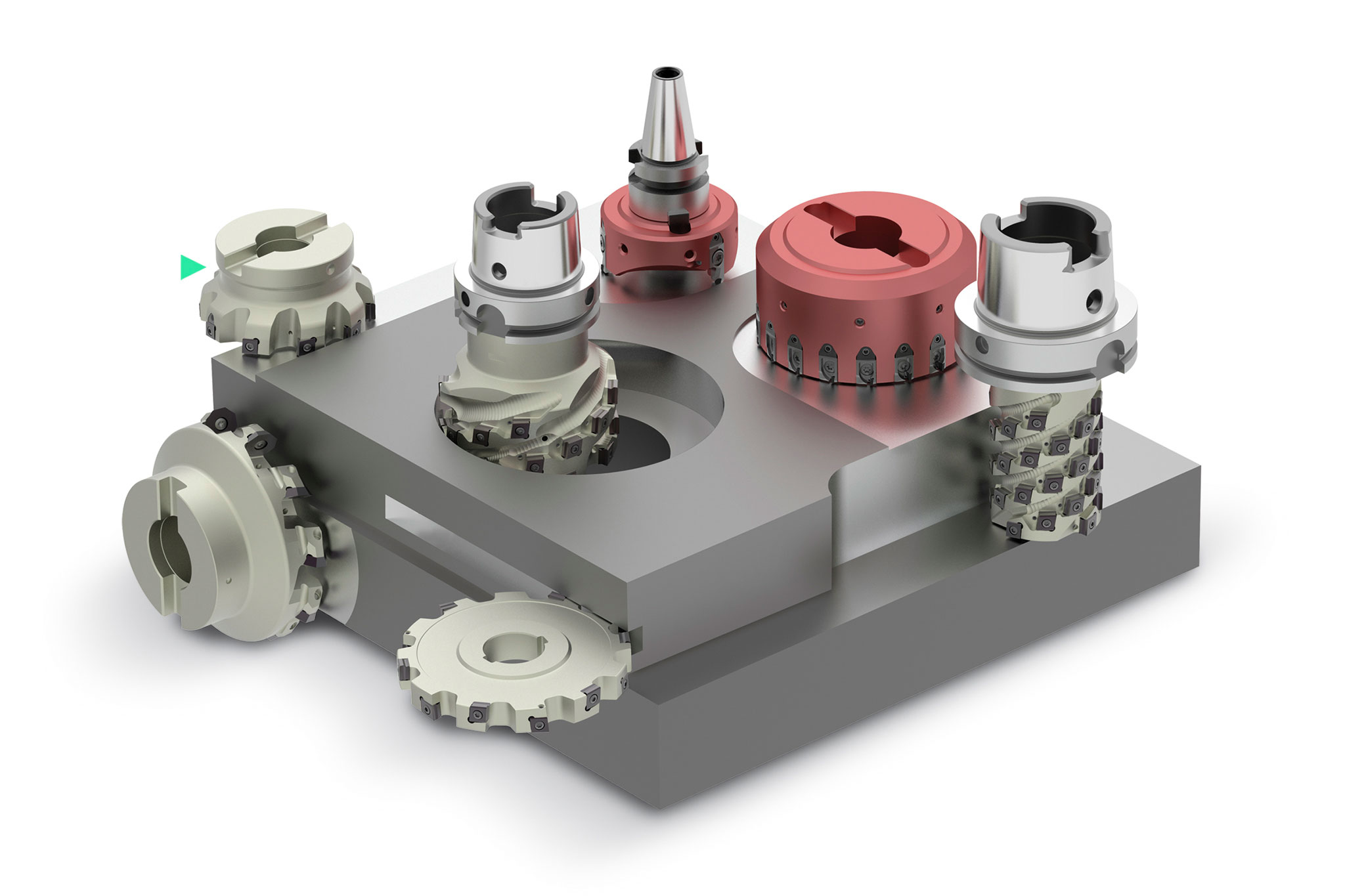

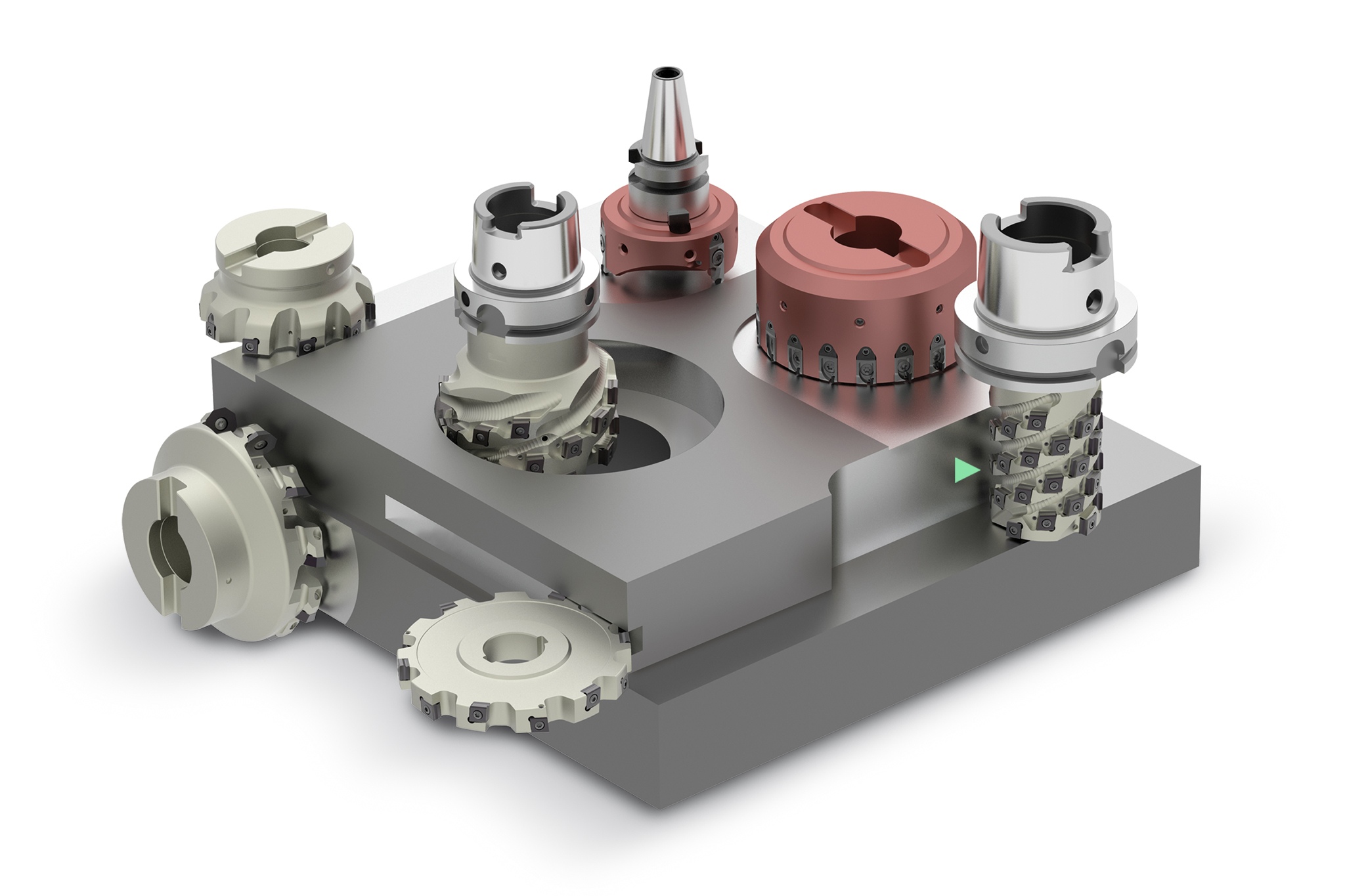

Fresas com insertos intercambiáveis radiais

O portfólio de ferramentas de fresagem padrão é complementado com um programa de fresagem muito econômico com insertos ra diais intercambiáveis ISO prensados. As novas fresas de alto desempenho de facear, de esquadrejamento, de canal e fresa frontal de cilindros são dimensionadas para desbaste e usinagem média de ferro fundido, aço e aço inoxidável.

Fresa plana

Desbaste e semi-usinagem de superfícies planas.- Altamente rentável devido aos insertos intercambiáveis radiais sinterizados

- Profundidade de corte até ap = 5 mm

- Inserto intercambiável com oito arestas de corte e forma básica positiva para peças susceptíveis à vibração

- Inserto intercambiável com 16 arestas de corte e forma básica negativa

- Ângulo de posicionamento 45°

Fresa de esquadrejamento

Ideal para a fresagem de superfícies de ressalto 90°.- Insertos intercambiáveis radiais com duas, quatro e oito arestas de corte

- Insertos intercambiáveis com forma básica positiva para peças susceptíveis à vibração

- Profundidade de corte até ap = 11 mm

- Ângulo de posicionamento 90°

Fresas frontais de cilindros

Para a usinagem de desbaste com grandes profundidades de corte. Ideal para fresagem de esquadrejamento profunda e rebordear.- Insertos intercambiáveis radiais com duas ou quatro arestas de corte para diâmetros pequenos a partir de 25 mm

- Profundidade de corte até ap = 62 mm

- Ângulo de posicionamento 90°

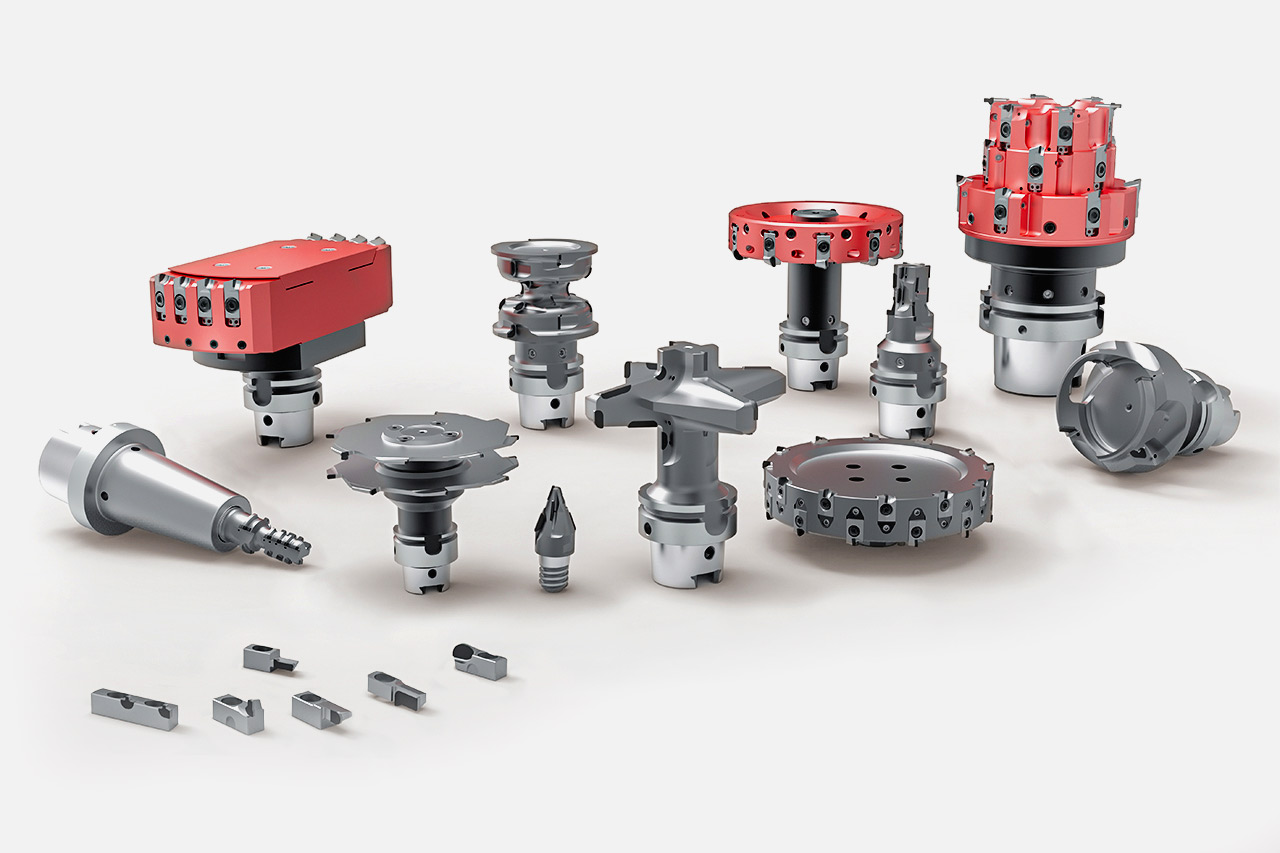

Soluções especiais com insertos de fresagem PCD

Soluções especiais específicas para o cliente, com arestas de corte PCD para as mais altas exigências.

- Fresas como ferramenta combinada para reduzir os tempos secundários

- Insertos de fresagem com formas e contornos específicos para o cliente são realizáveis

- Fresas de interpolação para contornos e canais complexos

Soluções especiais com insertos intercambiáveis

Ferramentas especiais específicas para o cliente, com elementos ISO para as mais altas exigências.

- Vantagens da tecnologia tangencial também para fresas especiais

- Fresas de múltiplos estágios reduzir a troca de ferramenta

- Ferramentas híbridas combinam diversos sistemas de ferramenta