Utensili con pattini di guida

Massima precisione con il principio MAPAL

Gli utensili con pattini di guida devono la loro elevata precisione e le alte prestazioni alla guida diretta all'interno del foro, consentita dagli appositi pattini di guida, nonché all'alta qualità delle lame ribaltabili affilate con massima precisione. E' proprio nella lavorazione fine del foro che i requisiti in termini di materiale da taglio, rivestimento, geometria dei taglienti e qualità di levigatura si fanno particolarmente elevati. Grazie a speciali sistemi di regolazione ad alta precisione è possibile realizzare i diametri desiderati con precisione micrometrica, fin dal primo pezzo in lavorazione. Il sistema EasyAdjust consente di ridurre sensibilmente i costi di regolazione, poiché l'unica regolazione necessaria per gli utensili è quella del diametro.

Alesatori a un tagliente

Alesatori a due taglienti

EasyAdjust-System

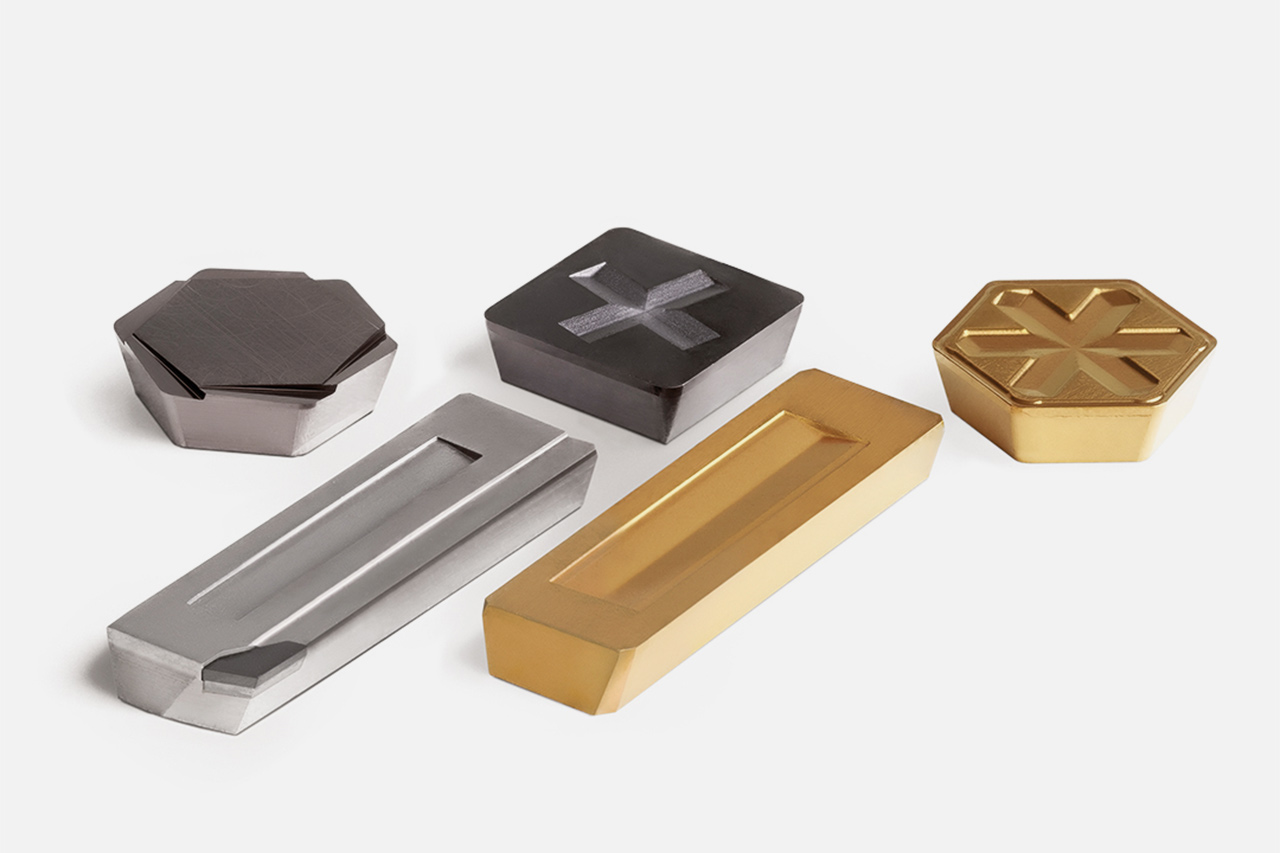

Indexable inserts

Along with the selection and design of the tool construction, the correct cutting material is of great importance for the quality and cost-effectiveness of machining.

Carbide, cermet, coatings, PCD and PcBN, the entire range of modern cutting materials is available from MAPAL for every workpiece material and for every machining task.

The latest manufacturing technology employed in the production of the indexable inserts today enables any chip former and chip breaker shape to be achieved – even on extremely hard cutting materials such as PcBN and PCD.

External and taper reamers

External reaming tools allow outside diameters and shafts to be machined efficiently and to the μm.

The principle of MAPAL external reaming is based on optimally absorbing and dispersing the cutting forces using guide pads so that no displacement forces and bending moments are exerted on the workpiece.

Taper fits in machine engineering place very high demands on surface finish, lead accuracy and circularity deviations to ensure the crucial contact ratio of the fit.

The MAPAL principle is also applied to taper reamers to machine reliably to the tightest tolerances.

Custom solutions

The primary application for guide pad-tools is mostly in large-scale series production. In addition to its standard programme, MAPAL also offers custom tools specially matched to the customer's application.

By means of special geometries, cutting materials and coatings, the tool can be designed for optimal machining results and high cost-effectiveness.

Tool combinations with other tool technologies enable customers to undertake complex tasks cost-effectively with only one tool.