07.07.2022

A turn of events

How the TET-CAM team is bringing project planning to another level

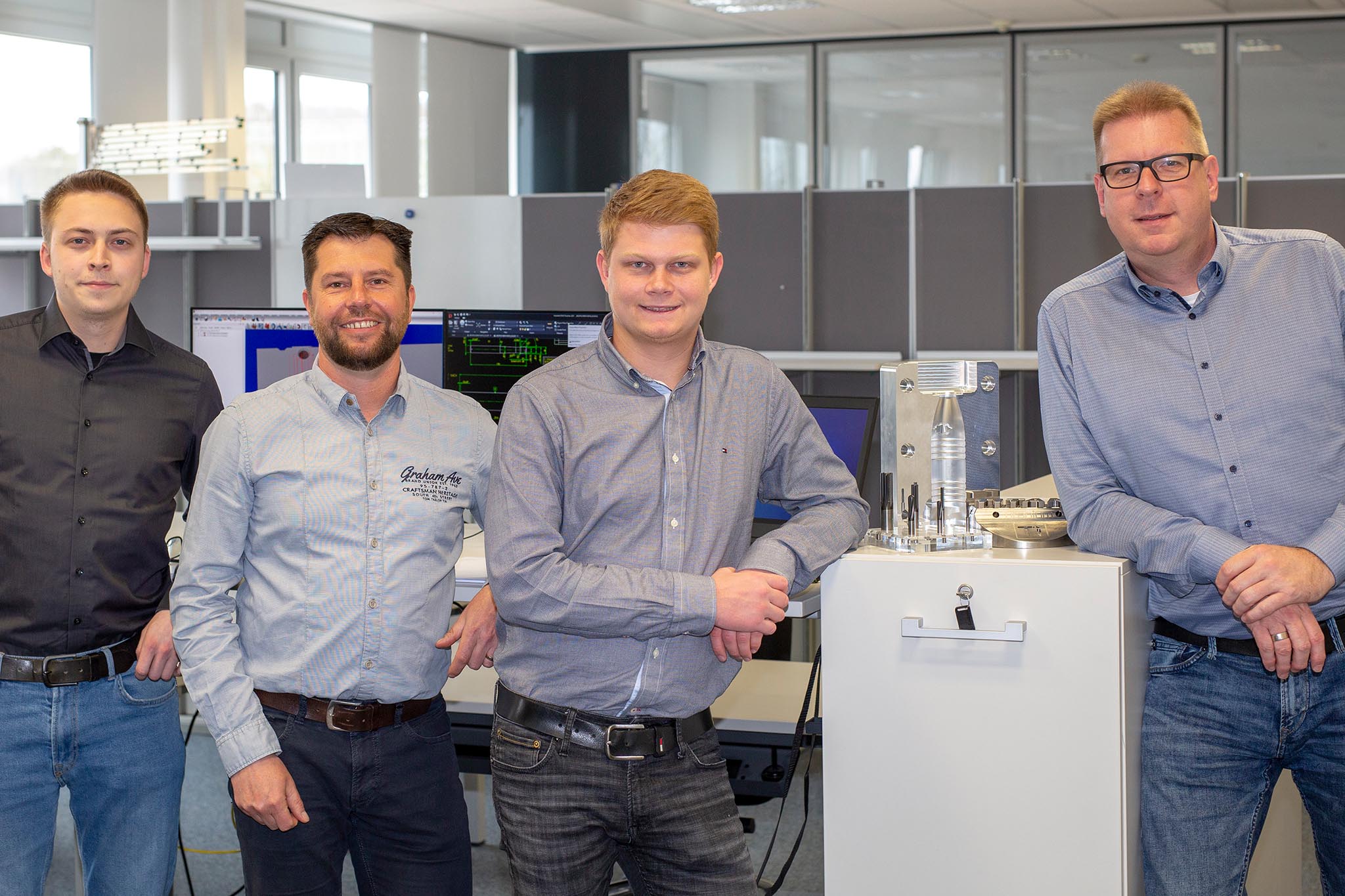

Since 1 April 2022, a newly formed team of CAM programmers in the Technology Expert Team (TET) in Aalen is developing machining strategies for parts and simulating various machining situations with CAM software. This is particularly valuable for the die & mould sector and the aerospace industry.

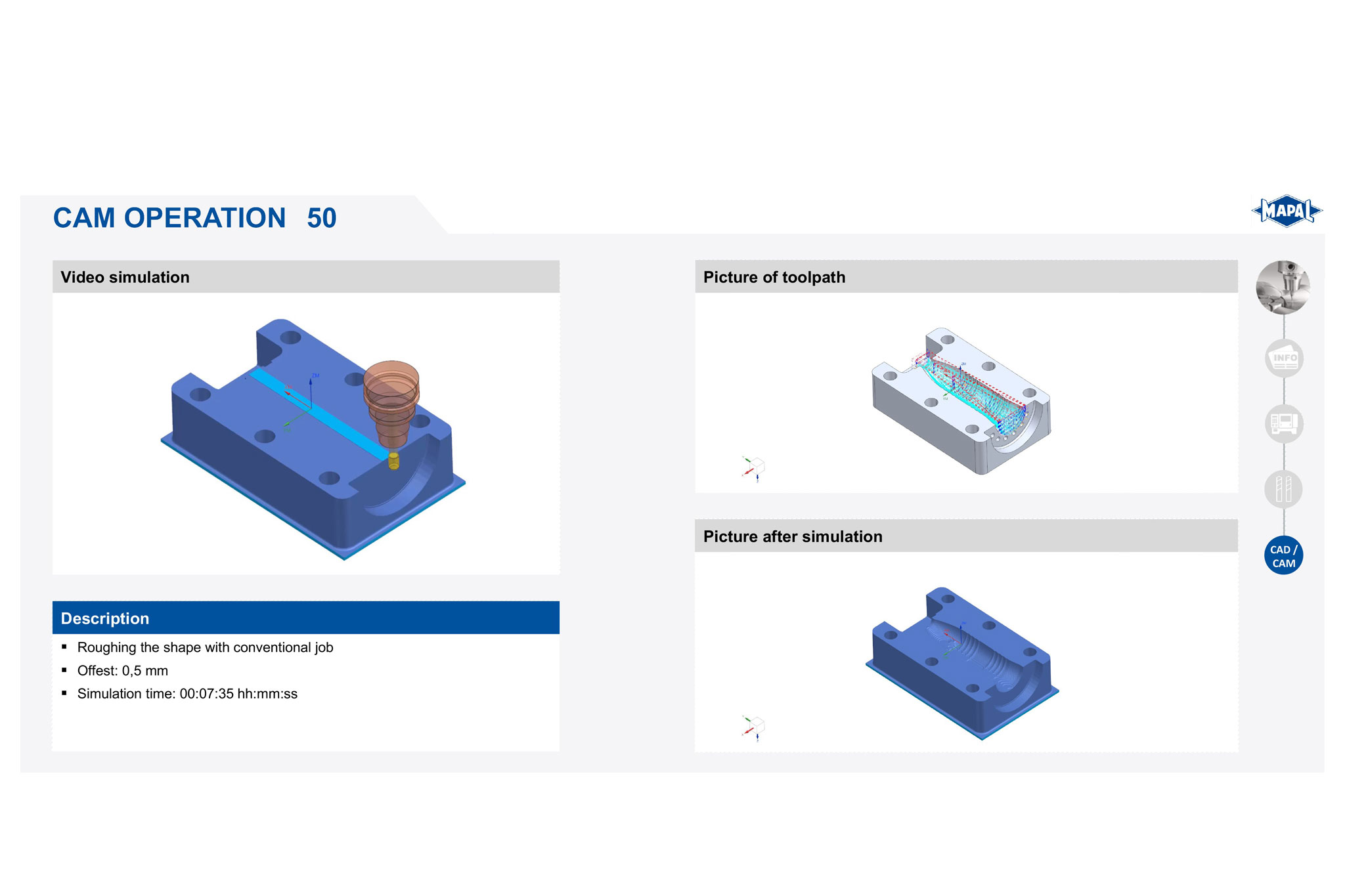

Structural parts, moulds or dies that are machined from the solid put different demands on the machining strategy than MAPAL’s classical bore machining. In projects related to the die & mould sector and the aerospace industry, the development of machining strategies is very important. 2D drawings and work plans are of little significance there. The machining strategy andoptimal tools have to be defined and then visualised and validated via smart CAM simulations for the customers.

CAM programmers provide support here. They are part of the TET project planning in Aalen where they have formed their own team since 1 April. “With the market entry in the die & mould sector, there was a big demand to provide our tools together with a machining suggestion”, explains Dietmar Maichel, Global Head of Segment Management Die & Mould. “We are happy to have found such expert support in the form of the TET-CAM team.” Lars Ziegler, Head of the TET-CAM team, adds: “Without the technical support of CAM software, it is difficult to visualise the milling paths of structural parts or moulds with angles or free-form surfaces.” The TET-CAM team’s support is not limited to certain market segments, but the commonalities with the die & mould sector and the aerospace industry are the biggest.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342