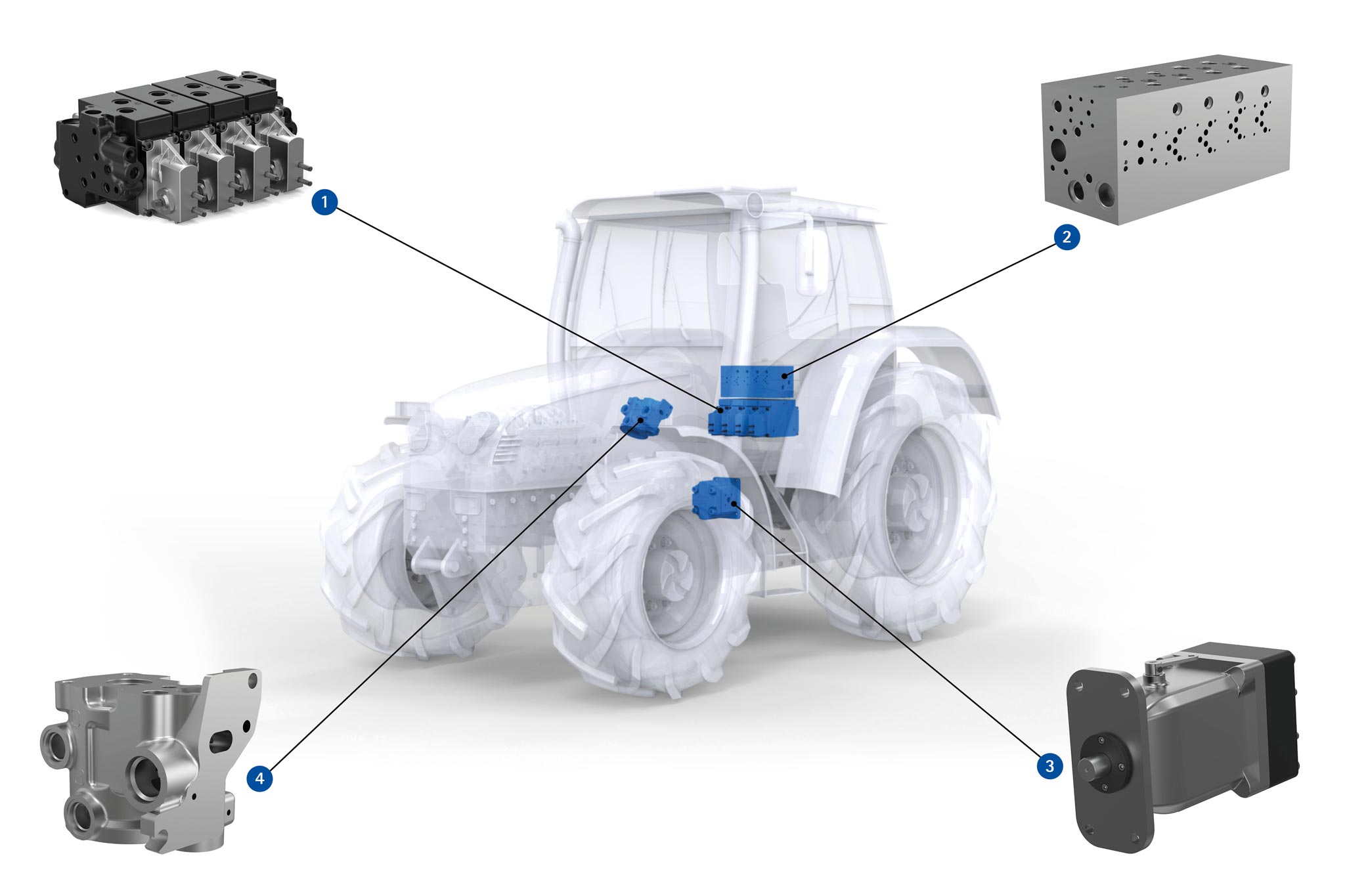

Bomba hidráulica

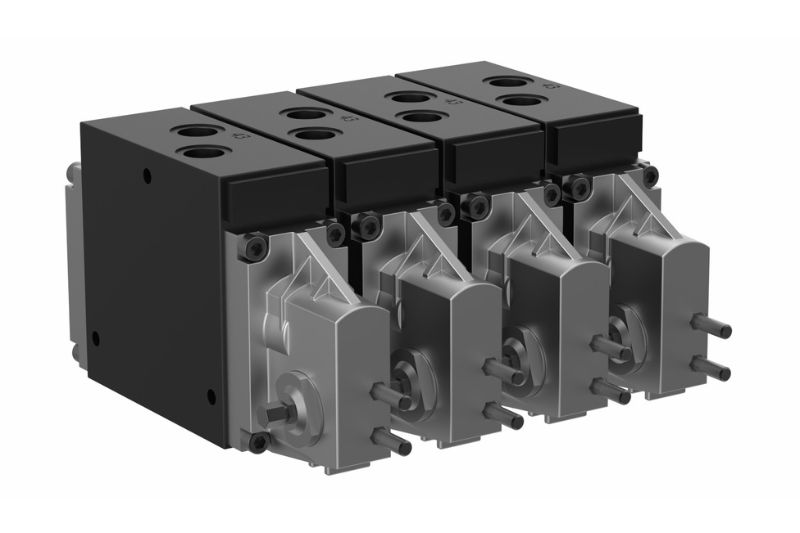

- (1) Carcasas de válvulas hidráulicas

-

Soluciones de mecanizado para las carcasas de válvulas hidráulicas

Todo depende de la perforación principal. La fabricación de carcasas de válvula es la disciplina estrella del mundo de la tecnología de fluidos. Desde hace años, la experiencia de MAPAL en el sector de mecanizado de perforaciones de corredera ha sido muy demandada. De la exactitud de esta perforación depende la dimensión de la ranura con la corredera para que el aceite hidráulico solo pueda fluir en la dirección deseada sin que se produzcan

fugas. Se trata de una definición muy estrecha para las válvulas hidráulicas modernas.

Por este motivo, es necesario prestar especial atención a

la circularidad, la forma cilíndrica, la rectitud y la

Calidad de la superficie de esta perforación.Procedimiento básico – Análisis del proceso de mecanizado

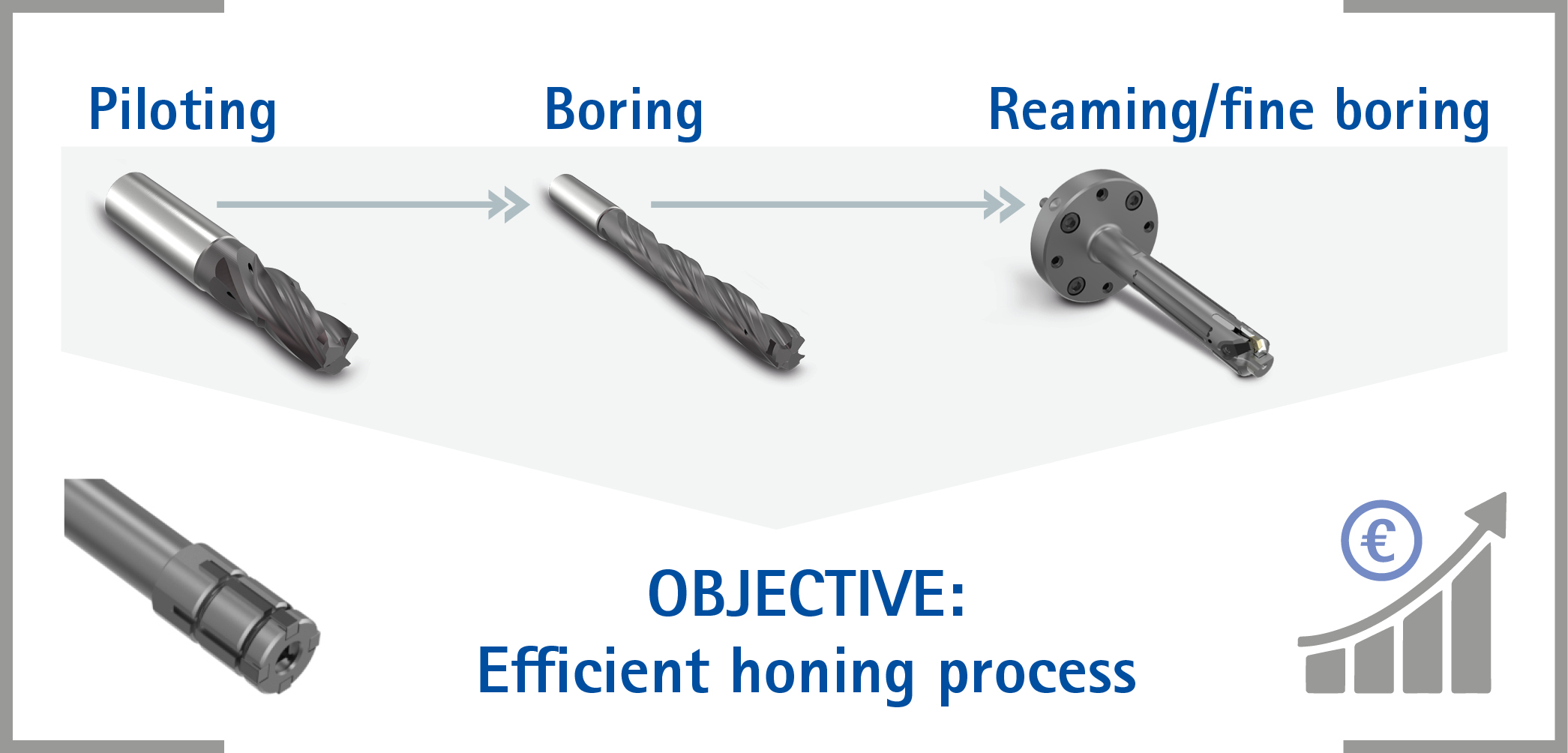

Como socio tecnológico, MAPAL apoya al cliente en el diseño completo del proceso. Los expertos prestan atención especial a los factores de costo que suelen encontrarse en las perforaciones funcionalmente relevantes. Con base en el proceso respectivo de bruñido, los requerimientos de los componentes y el tamaño de los lotes, MAPAL diseña la estrategia perfecta de mecanizado en diálogo con el cliente.Un objetivo une todas las actividades: para diseñar el proceso más económico, empezando por el pilotaje, pasando por el mandrinado y el mecanizado semiterminado, hasta el eficiente proceso de bruñido. - (2) Bloque de control

-

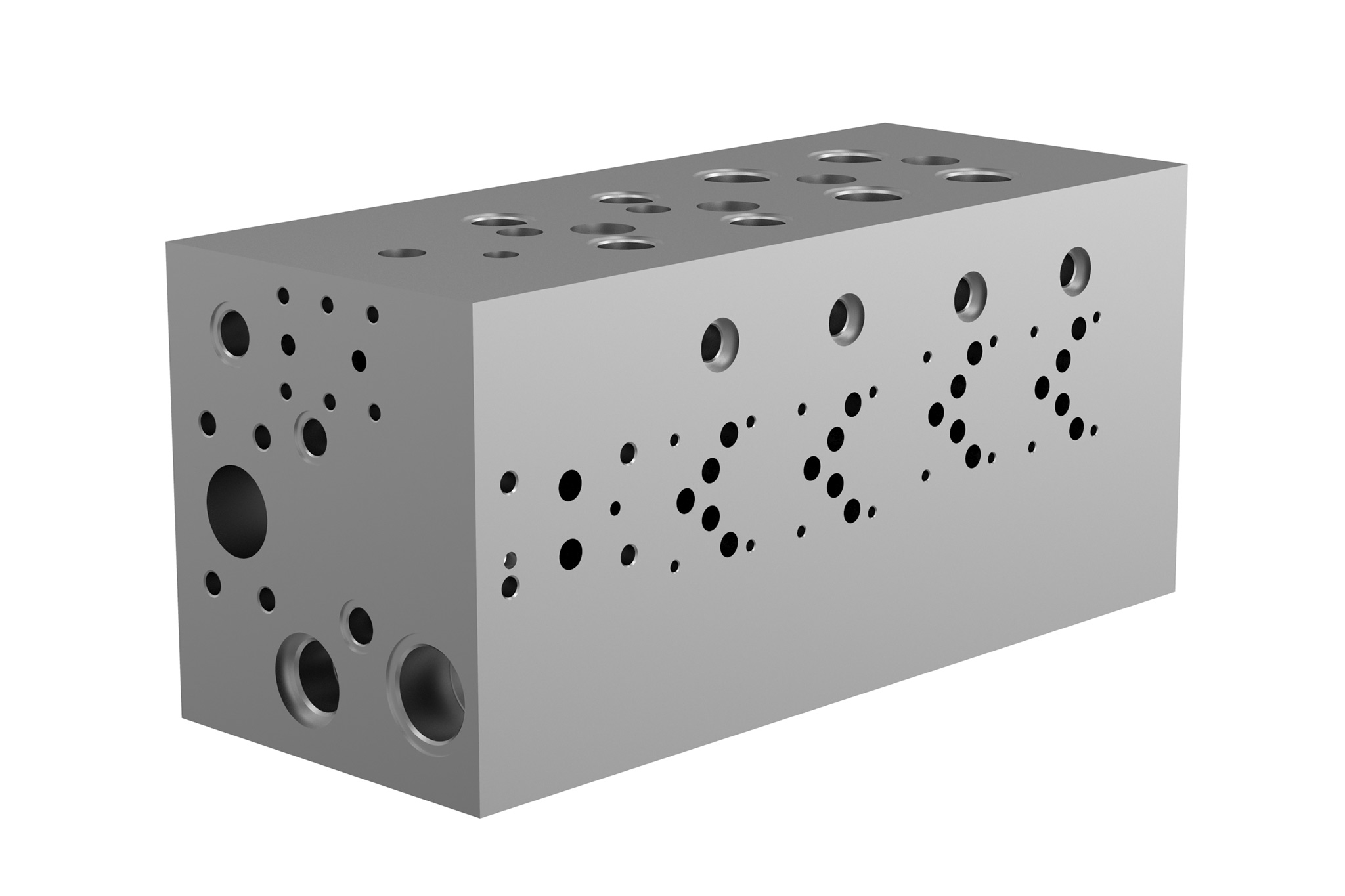

Bloque de control

El bloque de control hidráulico sirve como interfaz para diferentes válvulas y componentes de control. Esto se integran o se montan como agregados, y en su interacción, el bloque de control sirve como sistema regulador o distribuidor en los circuitos hidráulicos.Procedimiento básico – Análisis del proceso de mecanizado

Como socio tecnológico, MAPAL apoya al cliente en el diseño completo del proceso. Los expertos prestan atención especial a los factores de costo que suelen encontrarse en las perforaciones funcionalmente relevantes. Con base en el proceso respectivo de bruñido, los requerimientos de los componentes y el tamaño de los lotes, MAPAL diseña la estrategia perfecta de mecanizado en diálogo con el cliente.

Un objetivo une todas las actividades: para diseñar el proceso más económico, empezando por el pilotaje, pasando por el mandrinado y el mecanizado semiterminado, hasta el eficiente proceso de bruñido

- (3) Máquina de pistones axiales

-

Axial piston pump

El término máquina de pistones axiales abarca bombas y motores de pistones axiales. La bomba de pistones axiales convierte la energía mecánica en energía hidráulica, mientras que el motor de pistones axiales convierte la energía hidráulica en energía mecánica.

Las máquinas de pistones axiales se caracterizan por una gran estabilidad y un buen sellado interno, lo que permite altas presiones.Procedimiento básico – Análisis del proceso de mecanizado

Como socio tecnológico, MAPAL apoya al cliente en el diseño completo del proceso. Los expertos prestan atención especial a los factores de costo que suelen encontrarse en las perforaciones funcionalmente relevantes. Con base en el proceso respectivo de bruñido, los requerimientos de los componentes y el tamaño de los lotes, MAPAL diseña la estrategia perfecta de mecanizado en diálogo con el cliente.

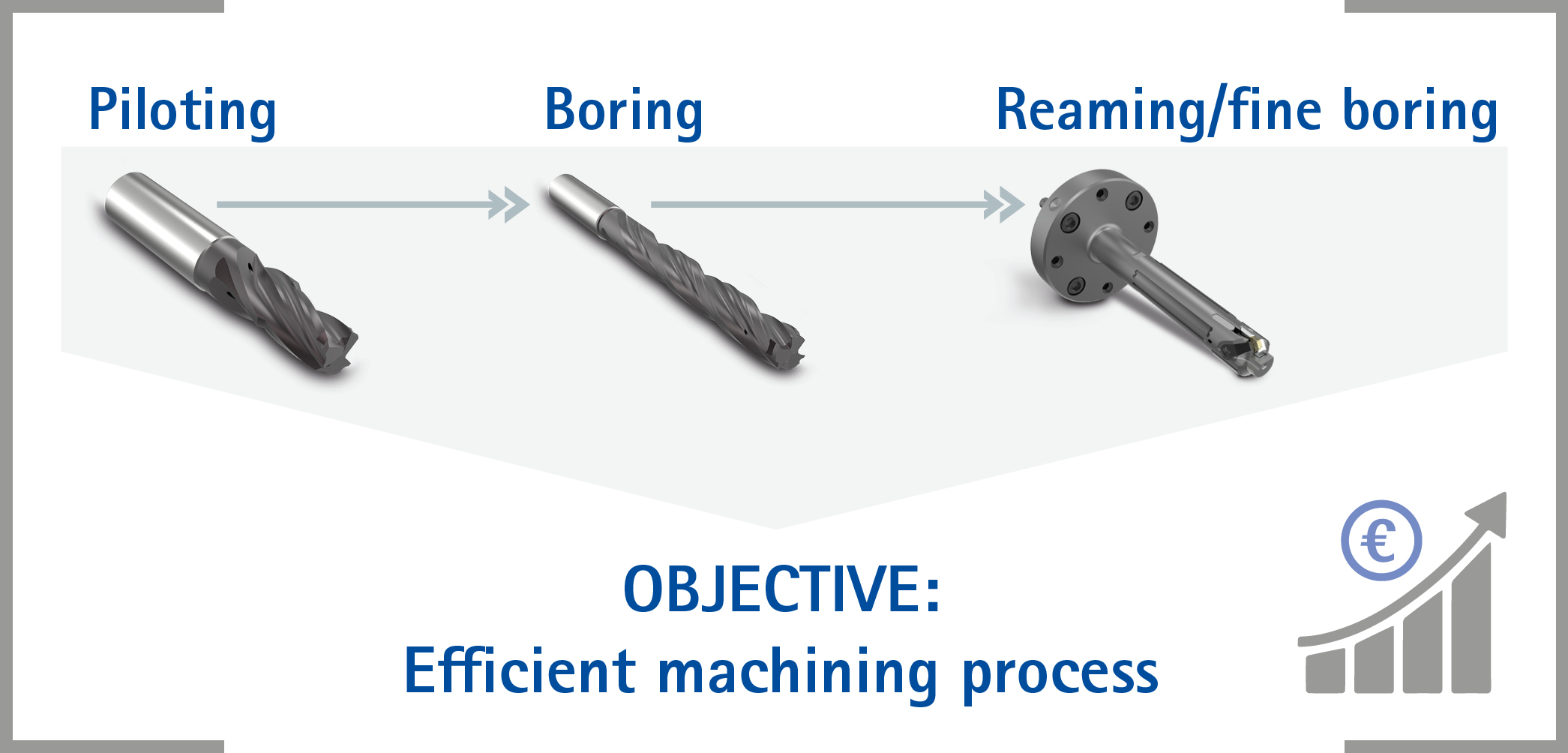

Un objetivo une todas las actividades: para diseñar el proceso más económico, empezando por el pilotaje, pasando por el mandrinado y el mecanizado semiterminado, hasta el eficiente proceso de bruñido

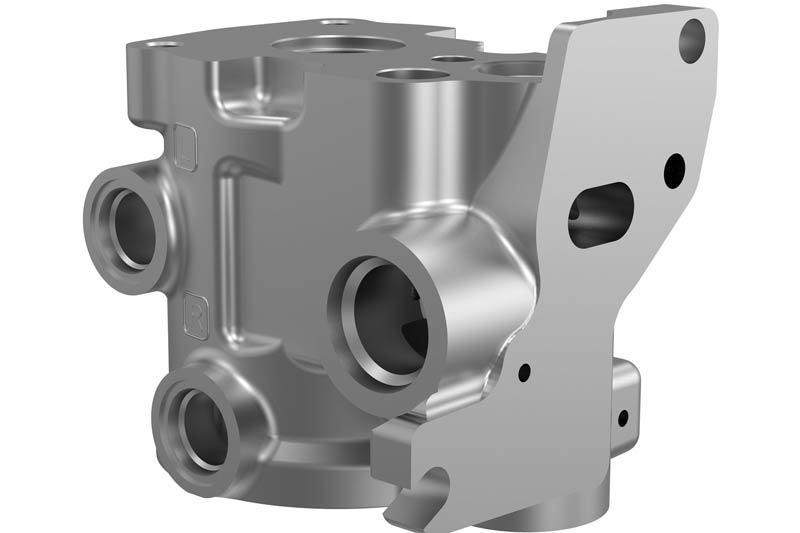

- (4) Orbitrol

-

Orbitrol

El orbitrol es el elemento de control central de la dirección hidrostática. El caudal transportado por una bomba hidráulica se canaliza según el movimiento del volante a los espacios de trabajo de un cilindro hidráulico, que activa la dirección de pivote. Para garantizar la función continua de las direcciones se utiliza una válvula de prioridades.Procedimiento básico – Análisis del proceso de mecanizado

Como socio tecnológico, MAPAL apoya al cliente en el diseño completo del proceso. Los expertos prestan atención especial a los factores de costo que suelen encontrarse en las perforaciones funcionalmente relevantes. Con base en el proceso respectivo de bruñido, los requerimientos de los componentes y el tamaño de los lotes, MAPAL diseña la estrategia perfecta de mecanizado en diálogo con el cliente.Un objetivo une todas las actividades: para diseñar el proceso más económico, empezando por el pilotaje, pasando por el mandrinado y el mecanizado semiterminado, hasta el eficiente proceso de bruñido.