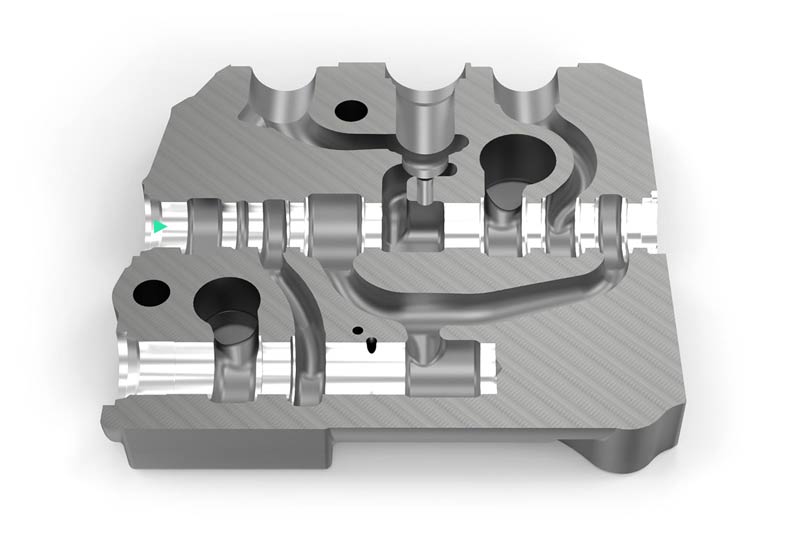

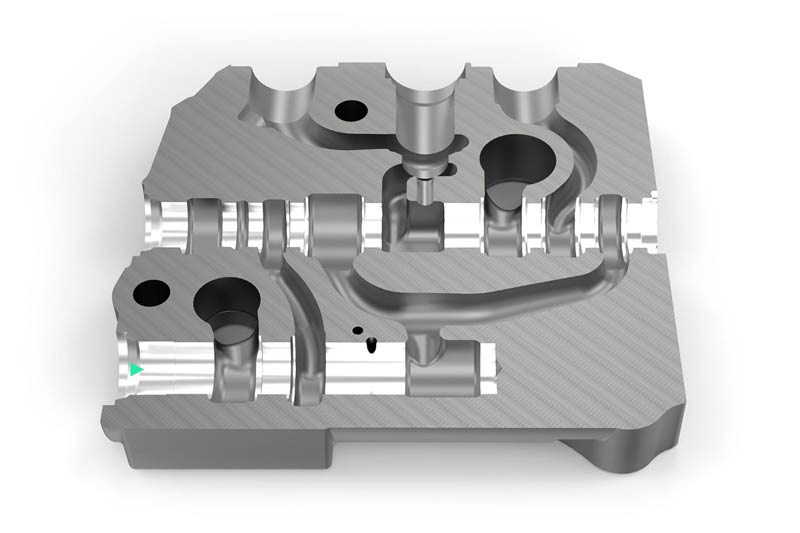

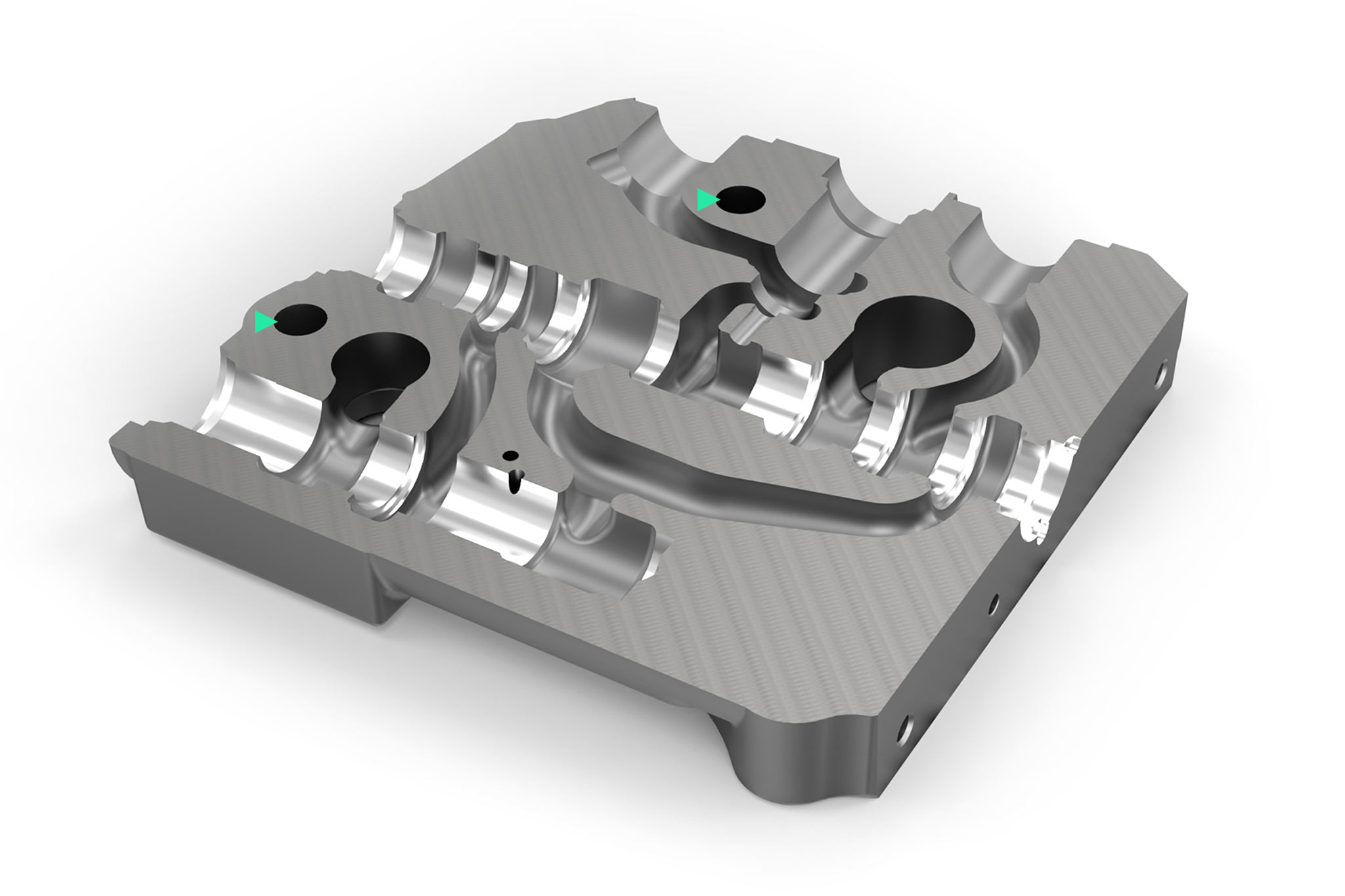

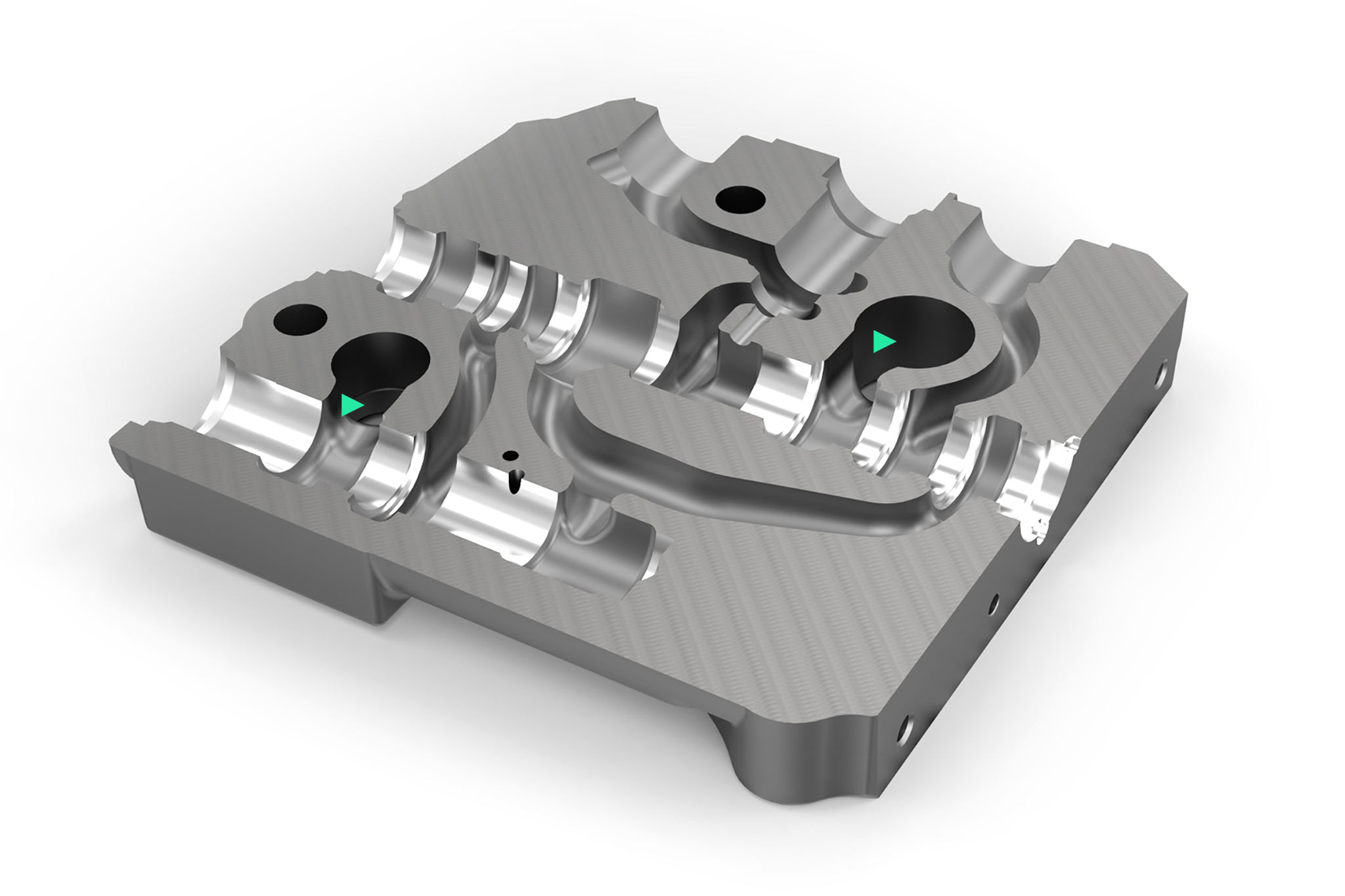

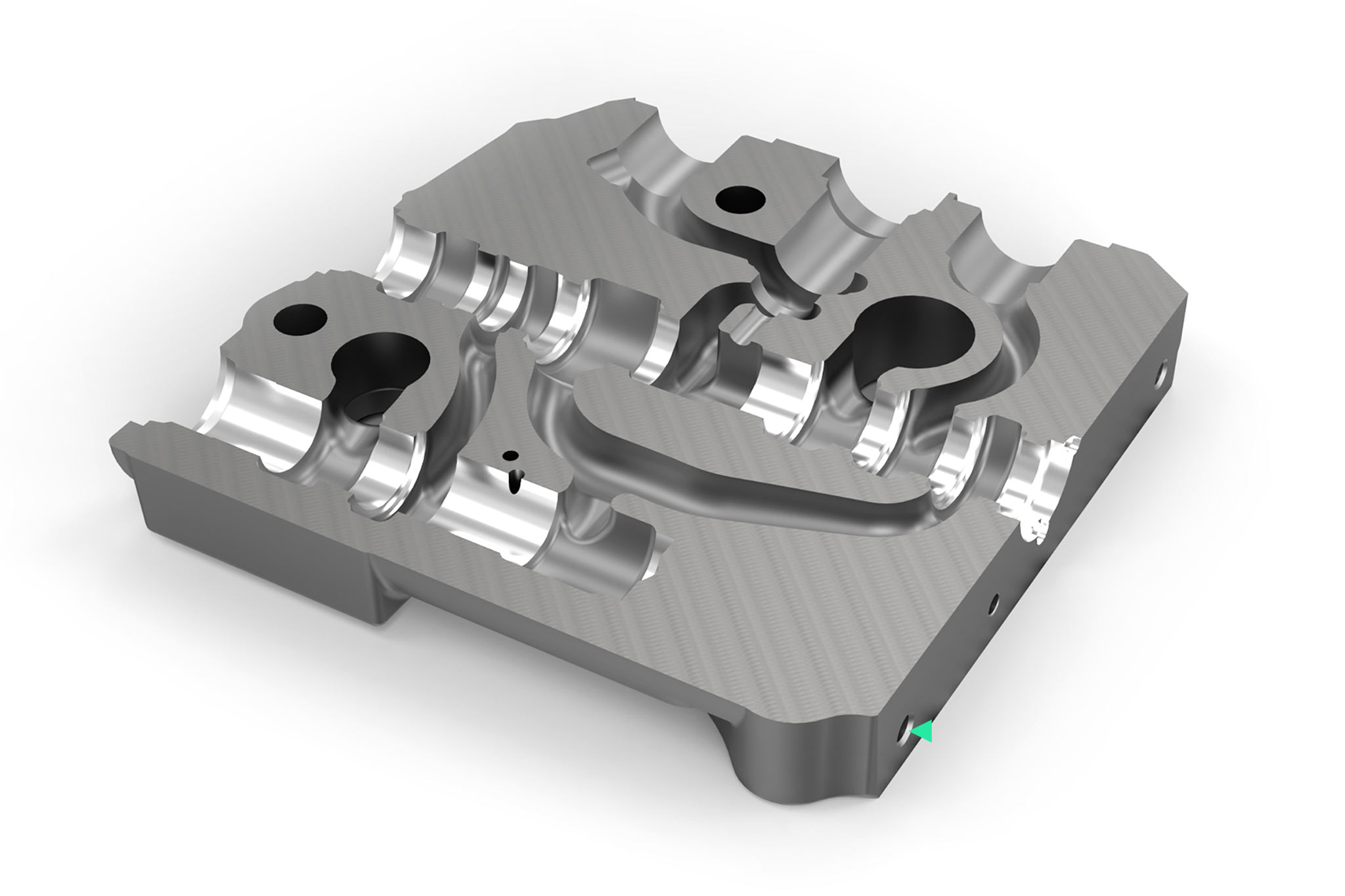

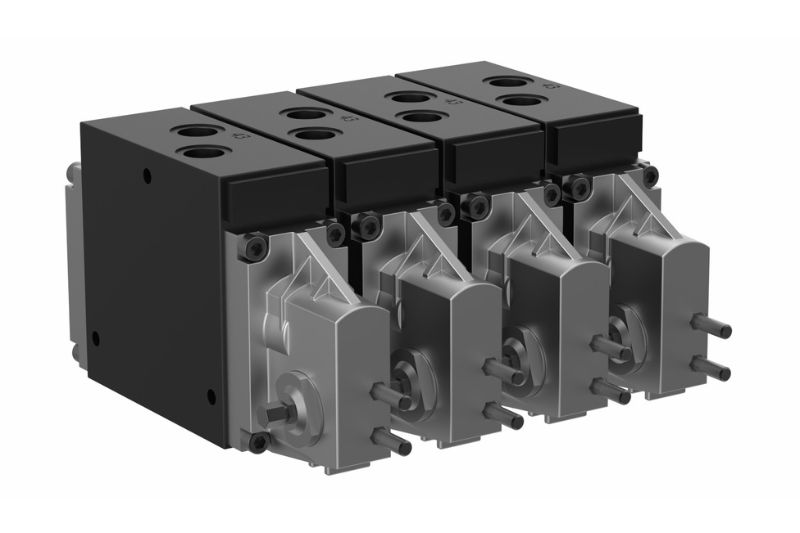

Carcasas de válvulas hidráulicas

Machining requirements

- Fluctuating cast allowance situation

- Heavily interrupted cuts

- Avoid ring formation during boring and ensure safe chip removal from the housing

- Avoid macroscopic flaws on the control edges in the boring process

- Very high demands on form and position tolerance

- Constant stock removal before honing

- Take part variance and limited tool storage places in the machining concept into account

Control valves are mechanically or electronically actuated valves with several switch positions. Depending on the specified position of the spool along the control edges, a volume flow is set for operating the connected working equipment. The individual pressure compensator adjusts a constant load pressure drop via the supply control edge of the spool, so that a load pressure-independent volume flow control is achieved across the whole adjusting range, also in parallel operation (load compensation). The system must be leakage-free, to prevent accidental dropping of the load, even with parallel operation.

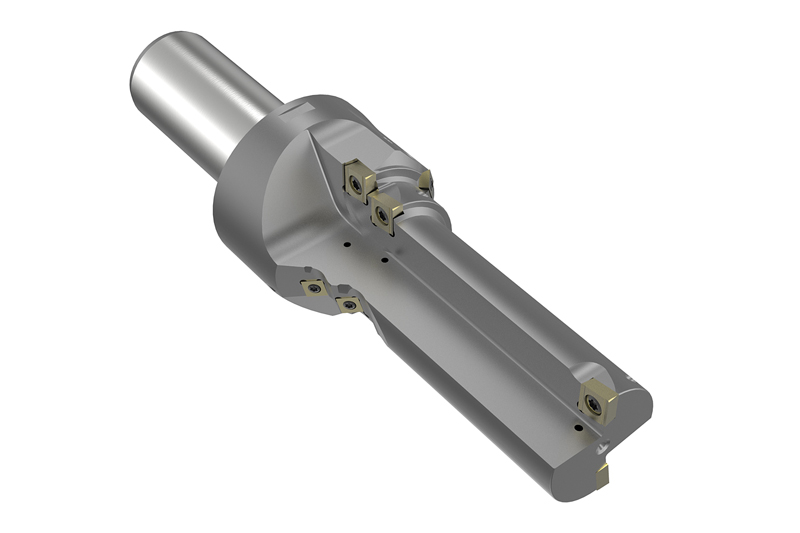

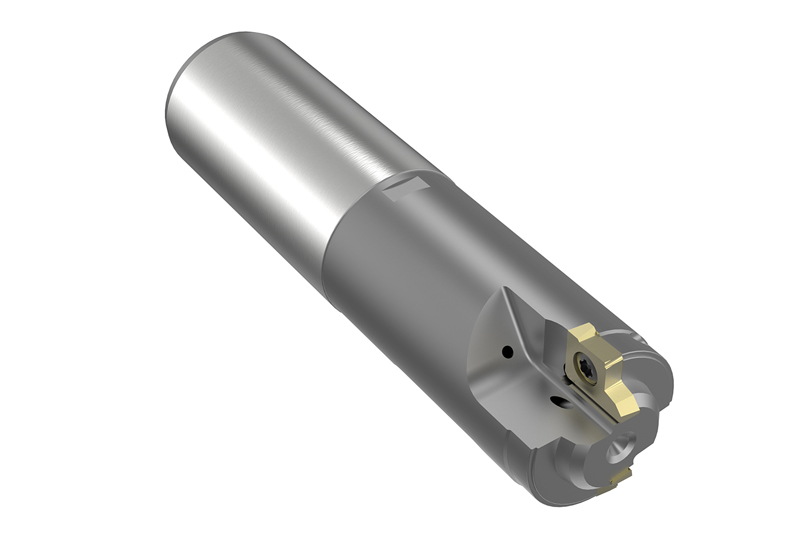

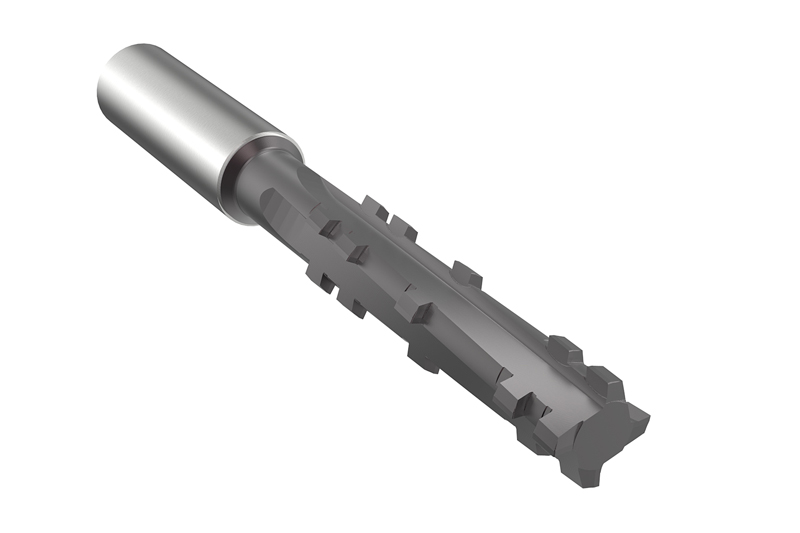

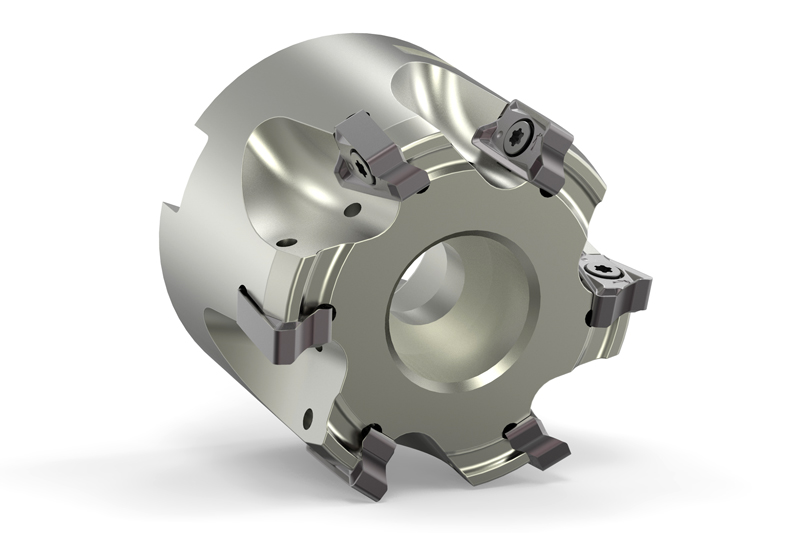

Bore machining

Application solutions

Initial situation at the customer

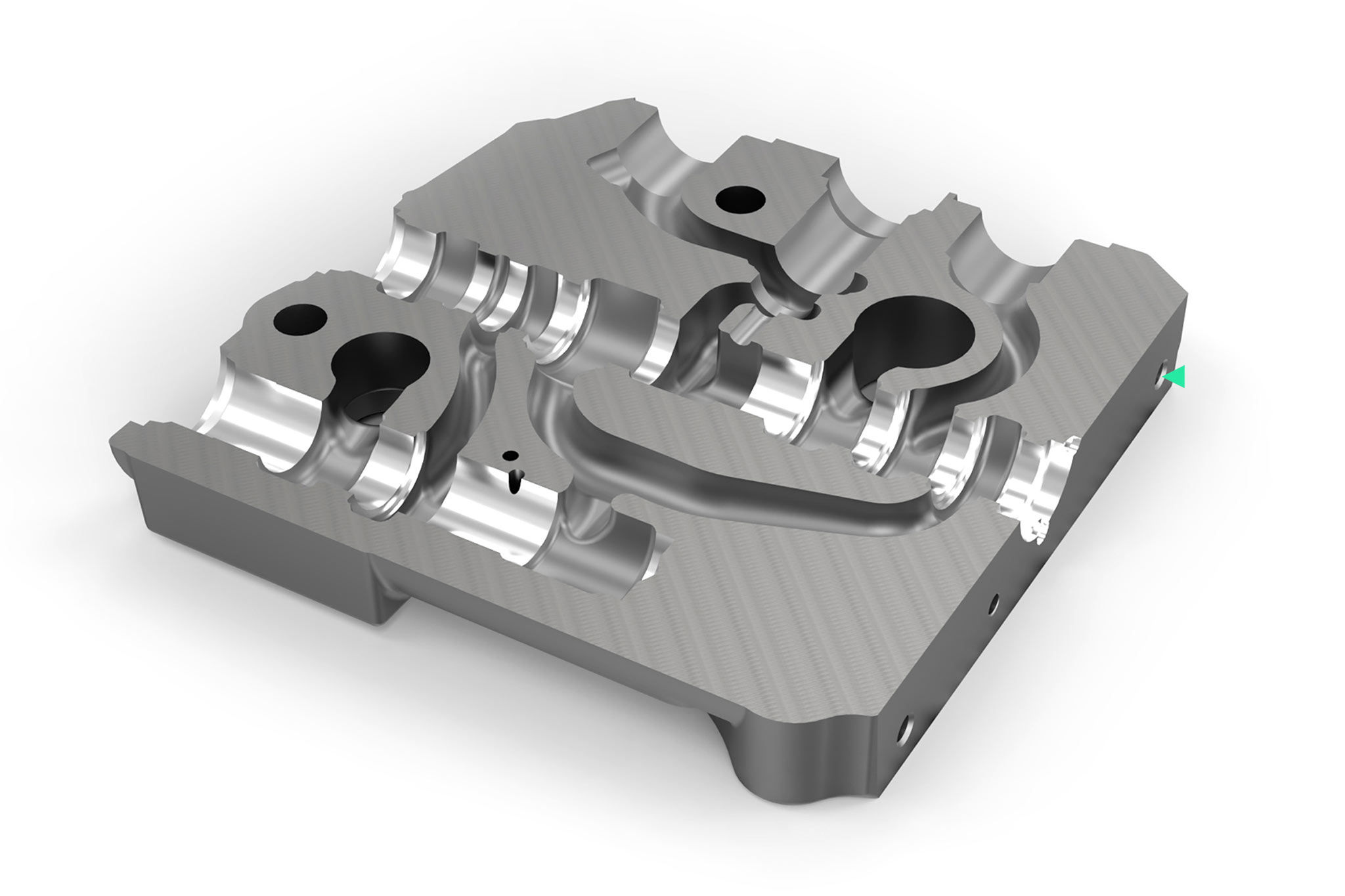

Valve housing EN-GJS-400-15 – spool bore

- Individual orders, smaller and medium quantities

- No option for tool setting

- Short cycle times required

- High machine hourly rates

- Stable oscillating honing available

- Tool concept adapted to several part versions

Initial situation at the customer

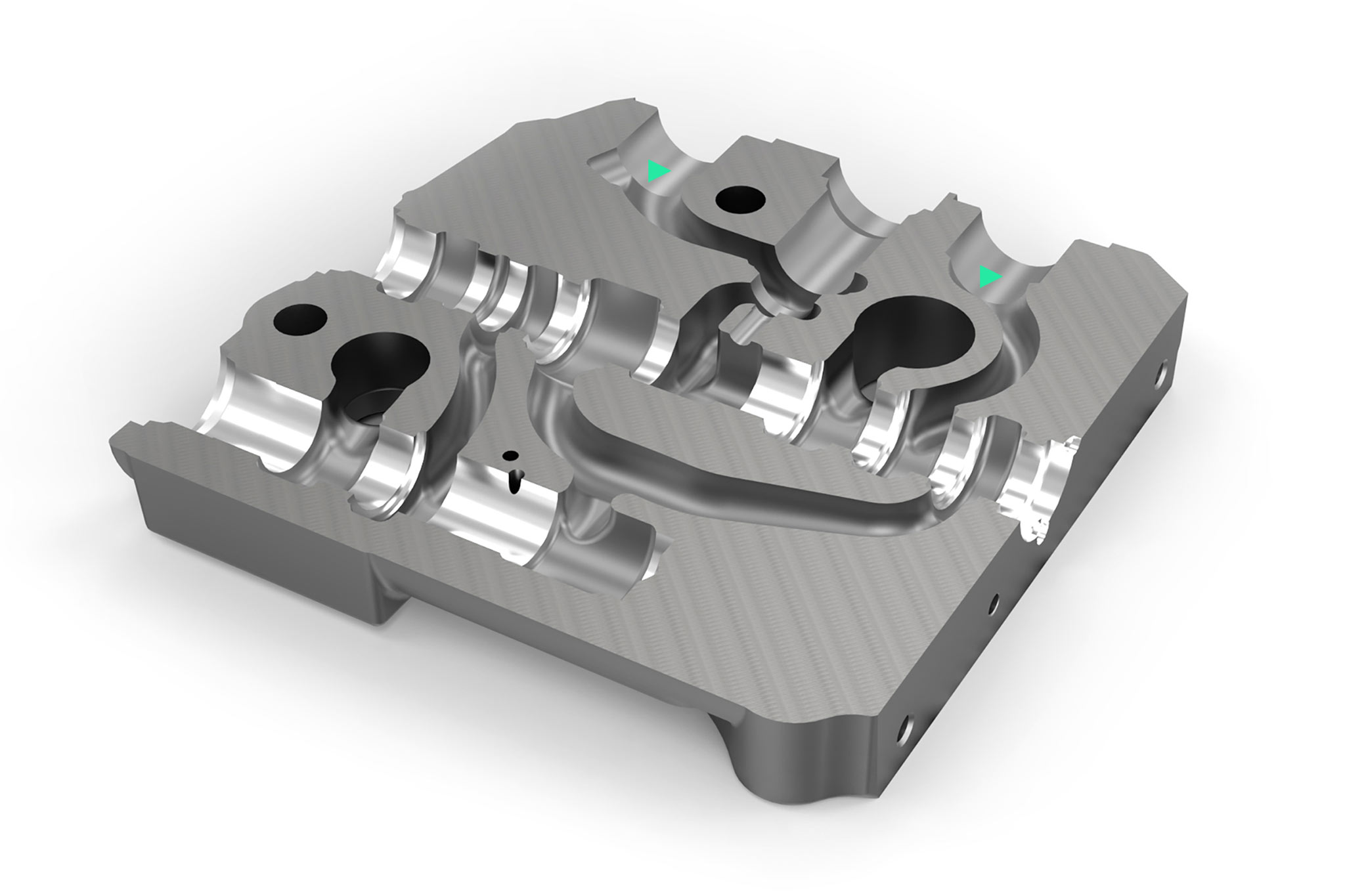

Valve housing EN-GJS-400-15 – spool bore and compensator bore

- Large-scale series

- Tool setting desired

- High machine hourly rates

- High costs for subsequent single pass honing

Initial situation at the customer

Valve housing EN-GJL-300 – spool bore

- Small lot sizes

- Option for tool setting available

- Too many/frequent tool changes

- High machine hourly rates

- High effort due to single pass honing process

Initial situation at the customer

Valve housing EN-GJS-400-15 – Compensator bore / honing

- Request for reduction of ancillary costs

- Existing machining centre re-tooled to TOOLTRONIC

- Honing for prototype manufacture, as well as small and medium-scale production runs

- Requirement for saving the honing process on separate machine

Initial situation at the customer

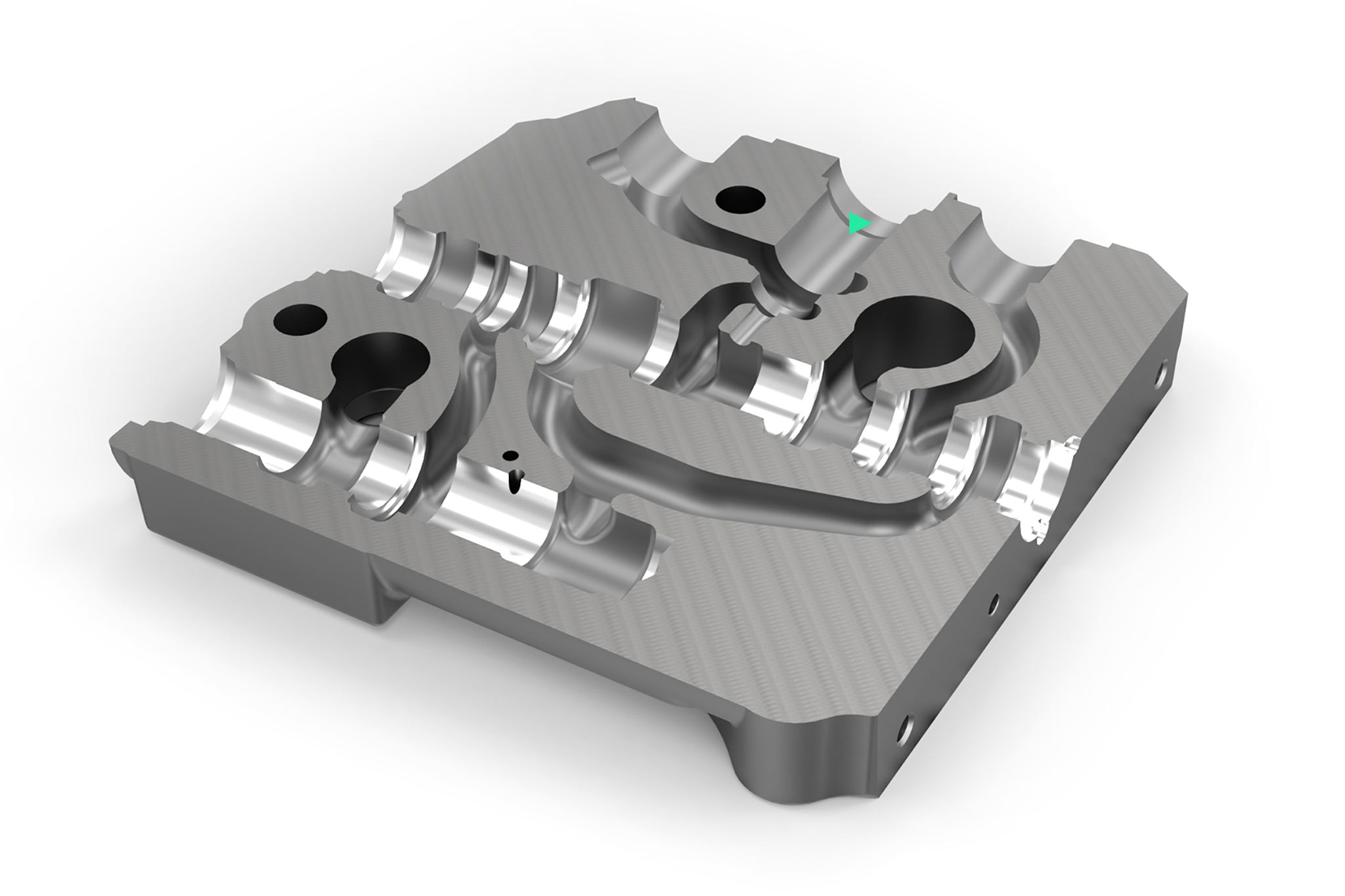

Valve housing EN-GJS-400-15 – complete machining

- High inventories

- Processes in the tool-setting area not optimal, and incomplete data quality

- Cost transparency is not sufficient

- High fluctuation due to general lack of skilled workers

- Problems with tool breakage

- High tool costs