30.06.2022

Even more cost-effective turbochargers

Radial standard milling range NeoMill from MAPAL

The transformation of mobility is in full swing. And so the focus has turned to developing new parts. However, it’s clear that motors with turbocharger will continue to be built for some time. Therefore, the machining business continues to strive for tool solutions with higher cutting values, longer tool life and thus lower costs per part. MAPAL has expanded its portfolio for turbocharger housing in order to make the entire machining process even more productive.

The turbocharger housing is a particularly worthwhile part to optimise in manufacturing as its machining involves a great deal of wear and tear. While the tool life for other car parts like cylinder crankcases, stub axles or brake calipers are in the thousands of parts, on average 30 to 140 turbocharger parts can be manufactured by a tool, depending on the machining length and workpiece material. Typically, turbochargers are made with the workpiece materials 1.4847, 1.4848, 1.4849 or 1.4837, which are heat-resistant stainless cast steels – a material that is extremely abrasive.

“If we manage to machine ten more parts per tool, it will have a very big effect on tool changing costs and thus the cost per part”, explains Heiko Rup, Product Manager for tools with indexable inserts. MAPAL is a proven partner for drilling and countersinking operations as well as contour machining. The precision tool manufacturer makes the entire turbocharger manufacturing process more economical with NeoMill milling cutters, which were introduced last year.

New milling cutters make MAPAL a complete supplier

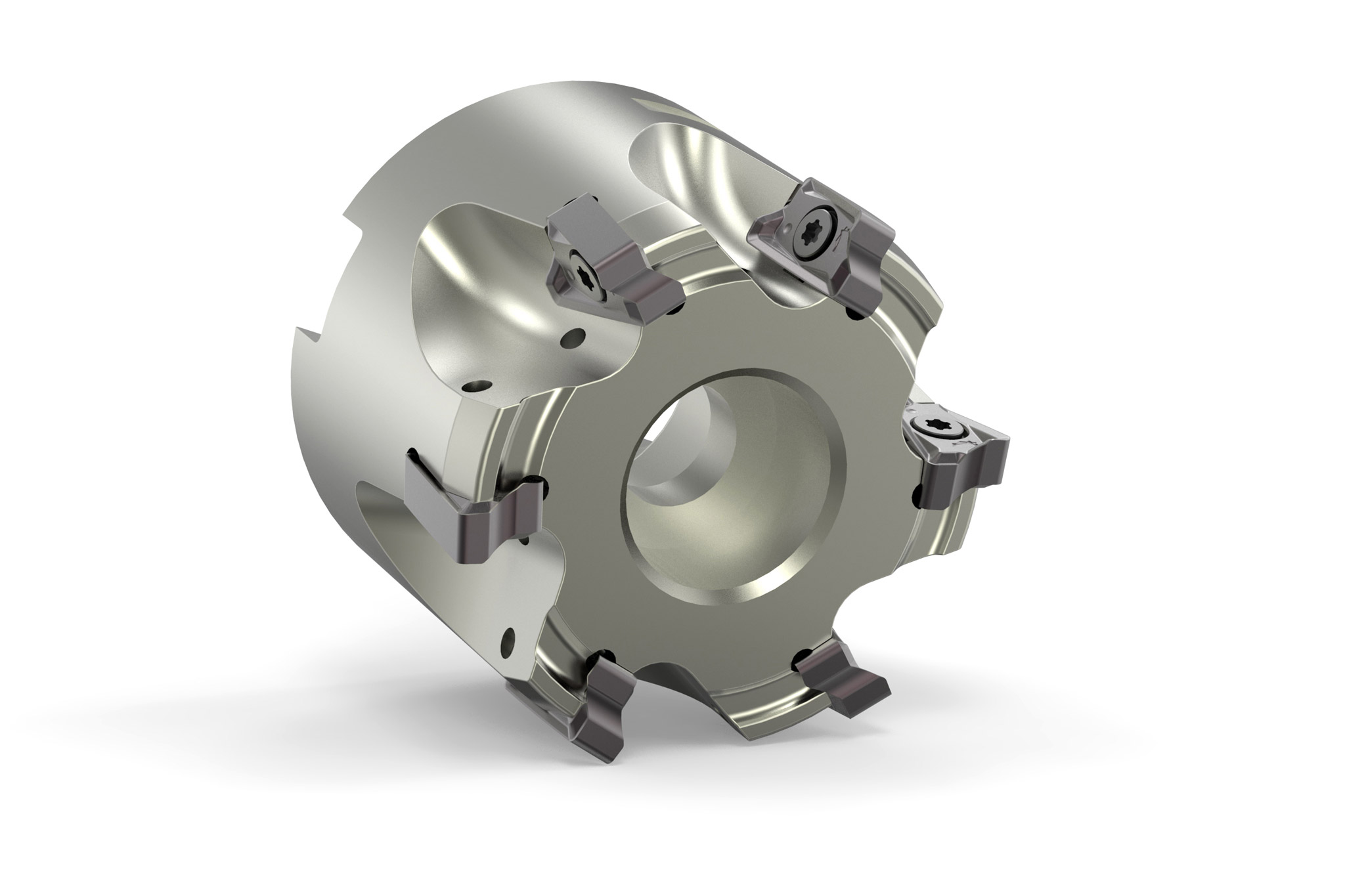

MAPAL has become a complete supplier for machining turbocharger housings with two milling cutters from the NeoMill portfolio: the face milling cutter NeoMill-16-Face and the shoulder milling cutter NeoMill-4-Corner. The face milling cutter machines the connecting surfaces of the manifold and exhaust flange on the turbocharger housing. A diameter range from 63 to 200 mm is offered with indexable inserts with 16 cutting edges. Only minimal cutting force occurs during machining.

Because of the clamping of the workpiece, tool restrictions can occur, in which case a shoulder milling cutter is required instead of a face milling cutter. The NeoMill-4-Corner shoulder milling cutter is equipped with four-edge indexable inserts, whose cutting edges also have a negative form. MAPAL developed a new chip guiding stage for this milling cutter especially for difficult to machine materials. For heat-resistant cast steel and stainless steels, it creates less cutting force and thus machines with minimal burr formation. The shoulder milling cutter is available for smaller diameter ranges from 25 to 100 mm.

In practice, turbochargers are machined both wet and dry. Thus, a wide variety of cutting material is available in the NeoMill range, which are optimised for dry machining, wet machining or machining with minimum quantity lubrication.

Due to the high degree of wear and tear, test of new tools quickly delivers tangible results. These have led many manufacturers to replace their old milling cutter with NeoMill.

Cost per part halved

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342