30.05.2023

Precisely fitting solutions for hydraulic valve housings

Customised machining solutions for individual manufacturing situations

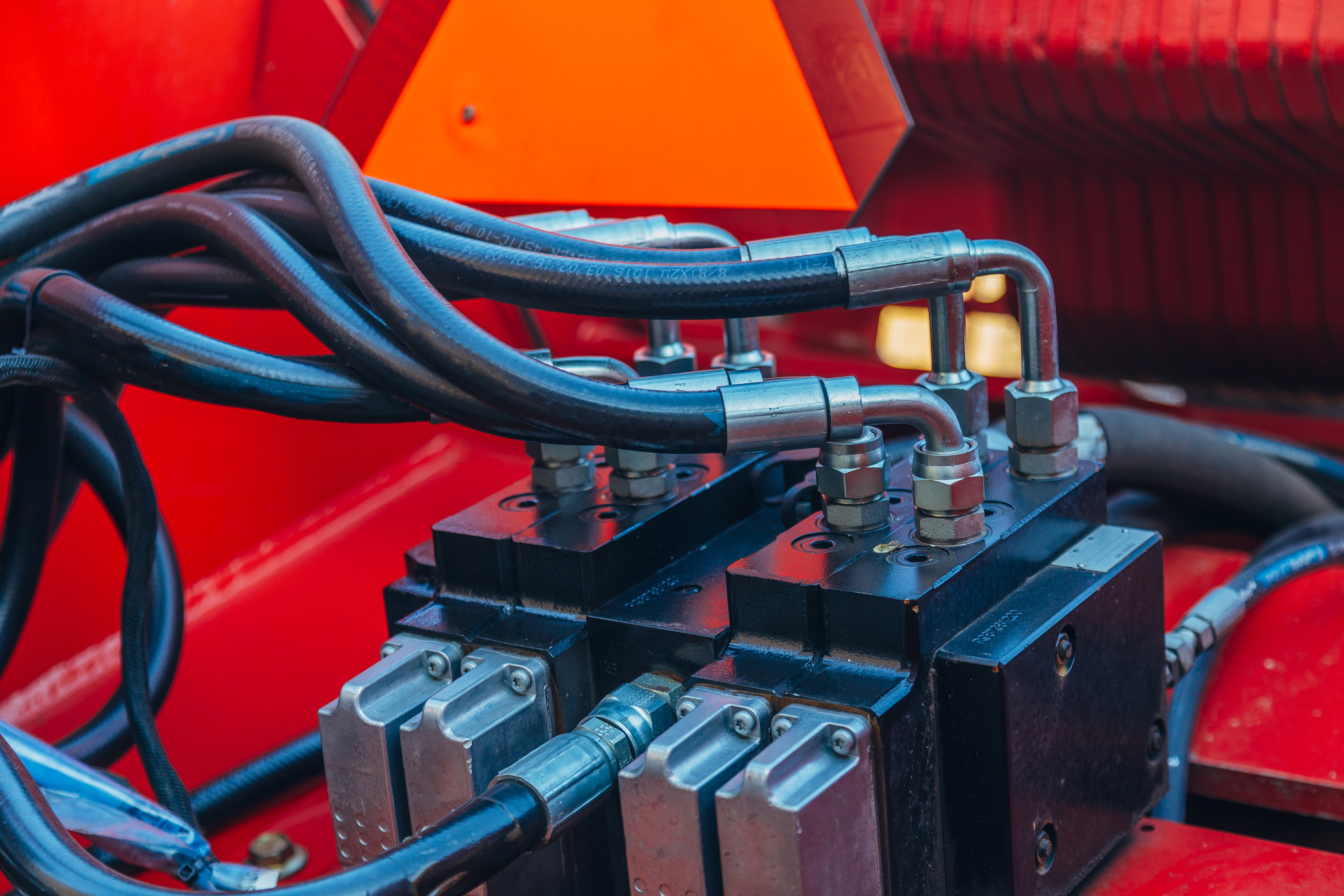

The production of hydraulic valve housings is the supreme discipline in the world of fluid power technology. As a technology partner, MAPAL supports the customer in the complete process design. The experts pay particular attention to the cost drivers that are often found in the functionally relevant bores. Based on the respective honing process, the component requirements and batch sizes, MAPAL designs the optimum machining strategy in dialogue with the customer.

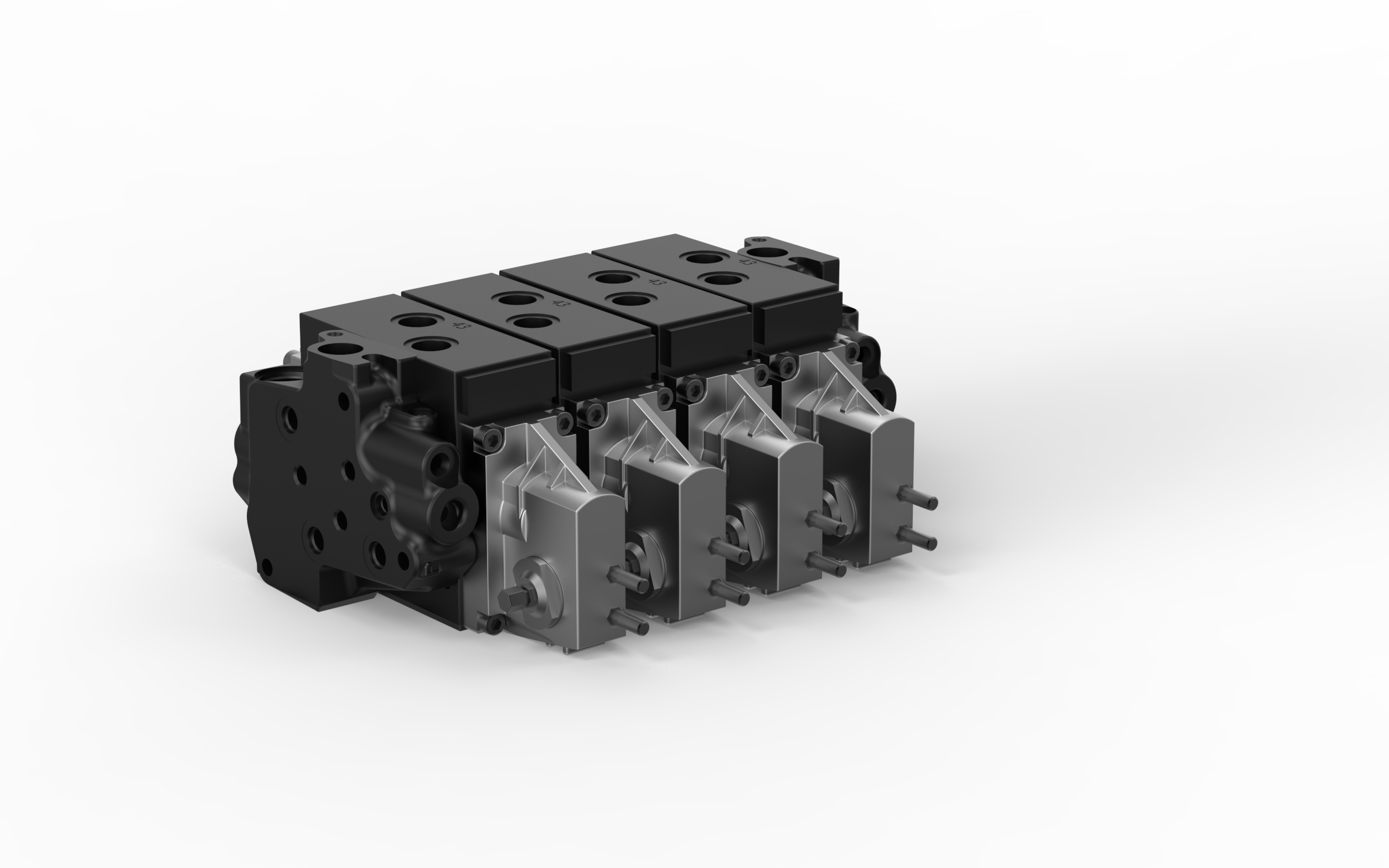

Based on the applications already implemented for existing customers, MAPAL has developed specific solutions for hydraulic valve housings. They reflect many customer and component requirements. For MAPAL’s expertise in machining the spool bore has been in demand for years. The gap dimension with the spool depends on the accuracy of this bore, so that the hydraulic oil can only flow in the required direction without leaking. This is very narrowly defined in modern hydraulic valves. The roundness, cylindrical form, straightness and surface quality of this bore are therefore crucial.

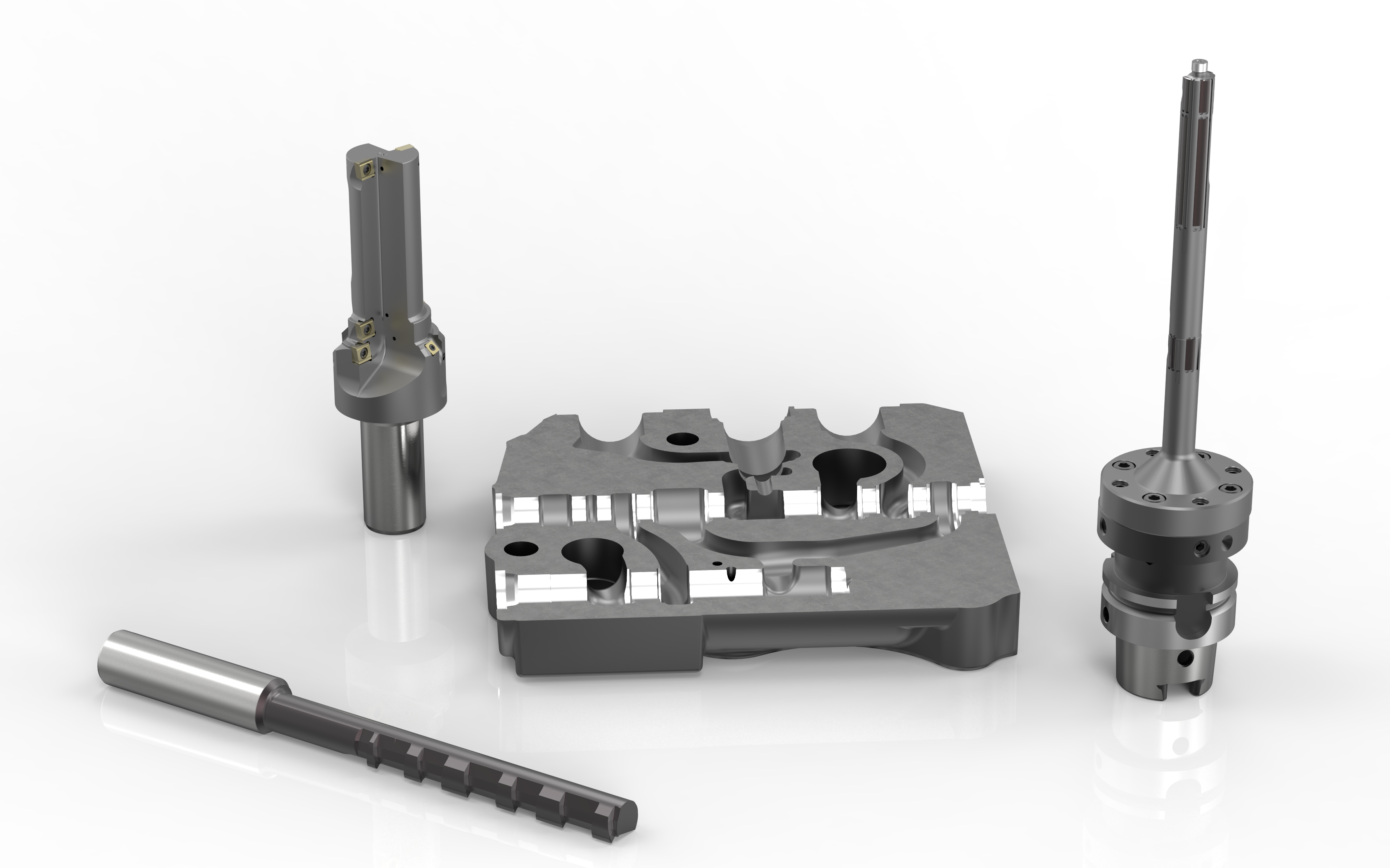

Clear best practice examples each deal with specific production situations. MAPAL designs the tools for these in a way that always results in the most cost-efficient process. That includes swiftly completing pre-machining and semi-finishing– all while keeping an eye on subsequent processes further down the line, such as honing.

Application solutions for every situation

Die erste der vorgestellten Lösungen für die Bearbeitung eines Hydraulikventilgehäuses ist eher untypisch für MAPAL, da sie ohne ein Feinbohrwerkzeug für die Finishbearbeitung auskommt. Nach dem Pilotieren, Aufbohren und Zirkularfräsen der Schieberbohrung macht hier eine Mehrschneidenreibahle den letzten Bearbeitungsschritt vor dem Honen. Mit der Werkzeugauswahl zeigt MAPAL, dass manche Aufgaben auch ohne ein einstellbares Spezialwerkzeug in hoher Genauigkeit lösbar sind. Das Konzept eignet sich vor allem für kleinere und mittlere Stückzahlen.

Wenn es in der Serienproduktion um große Stückzahlen bei höchster Genauigkeit geht, ist die zweite Anwendungslösung die passende Blaupause. Den entscheidenden Unterschied macht das zur Fertigbearbeitung eingesetzte Feinbohrwerkzeug, das die hohen Anforderungen an die Herstellung der Schieberbohrung und der Druckwaagenbohrung erfüllt. EasyAdjust-System und Führungsleisten stehen für eine prozesssichere Feinbearbeitung mit einfachem Handling. Als Technologiepartner klärt MAPAL zusammen mit dem Kunden, wie weit ein abschließender Honprozess reduziert werden kann oder sogar überflüssig wird.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342