01.02.2018

Concentrated flexibility and efficiency – facing heads and mounting tools from MAPAL

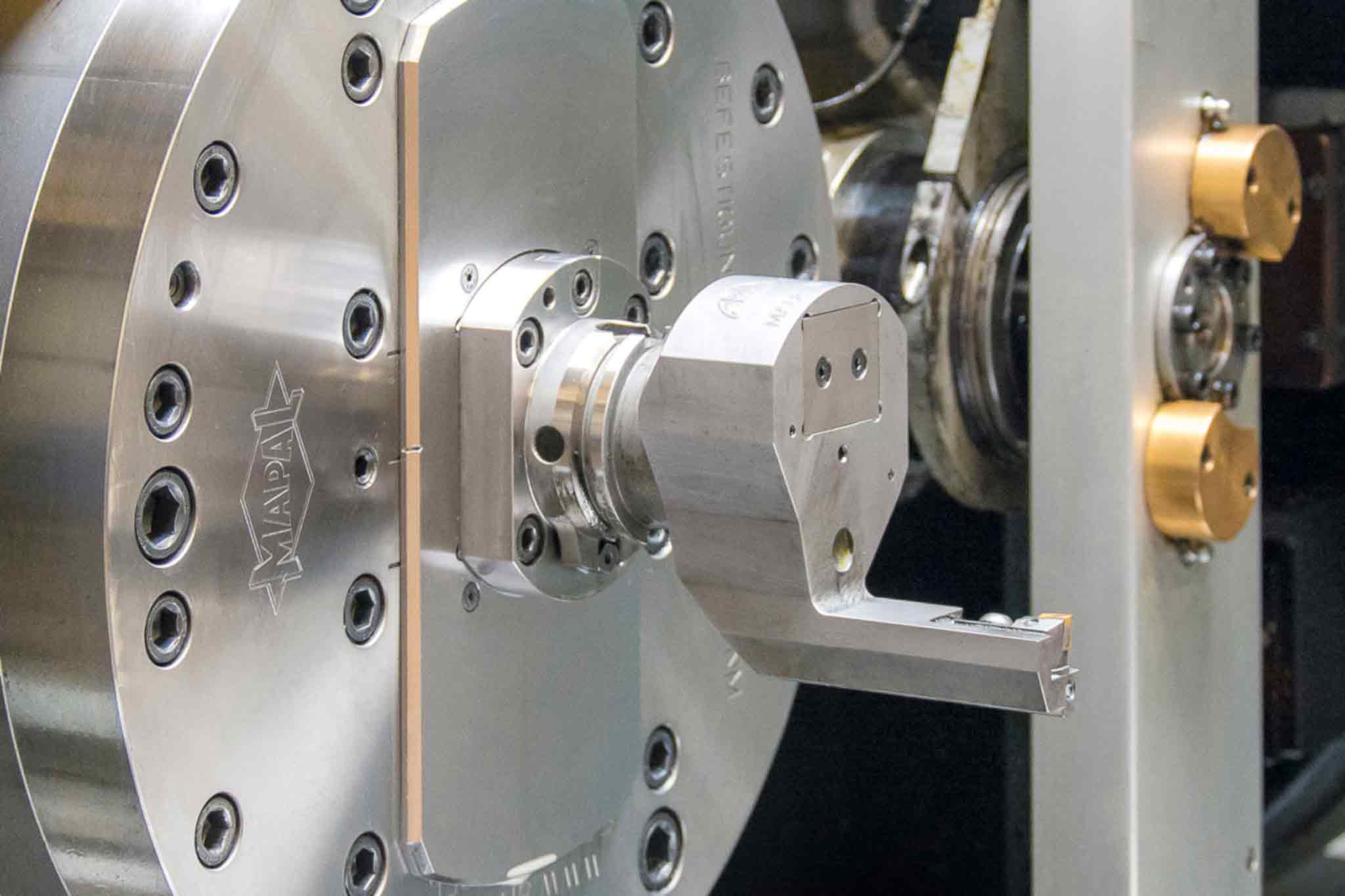

Using facing heads and mounting tools, complex contours on rotationally symmetric components can be realised without the use of a lathe for stationary workpieces. This benefits end machining centres when both pipe ends have to be machined simultaneously and independently of each other. The Bühring machine manufacturer therefore decided on a CNC machining centre with a corresponding tool solution from MAPAL and since then operates significantly more flexibly and economically.

Machine manufacturer Bühring machines complex contours with high efficiency and precision

The effort and commitment paid off. The machine fitted with the latest technology has significant advantages compared with the outdated system previously used.

Simultaneous machining of both pipe ends

- The single-slide facing heads:

- External diameter of 380 mm

- Face stroke of 55 mm

Other features of the facing head:

- Central oil lubrication

- Internal coolant supply

- Barrier air at the HSK connection which is used to automatically hold the mounting tools

“Along with high process reliability, one of biggest advantages of the new system that showed effect immediately is the significantly faster component

change”, explains Bühring. “Refitting on the system previously used took around 2.5 hours. We now require around half the time. This is noticeable as we generally change the product at least once a week.”

Automated tool change using HSK-A63 connection

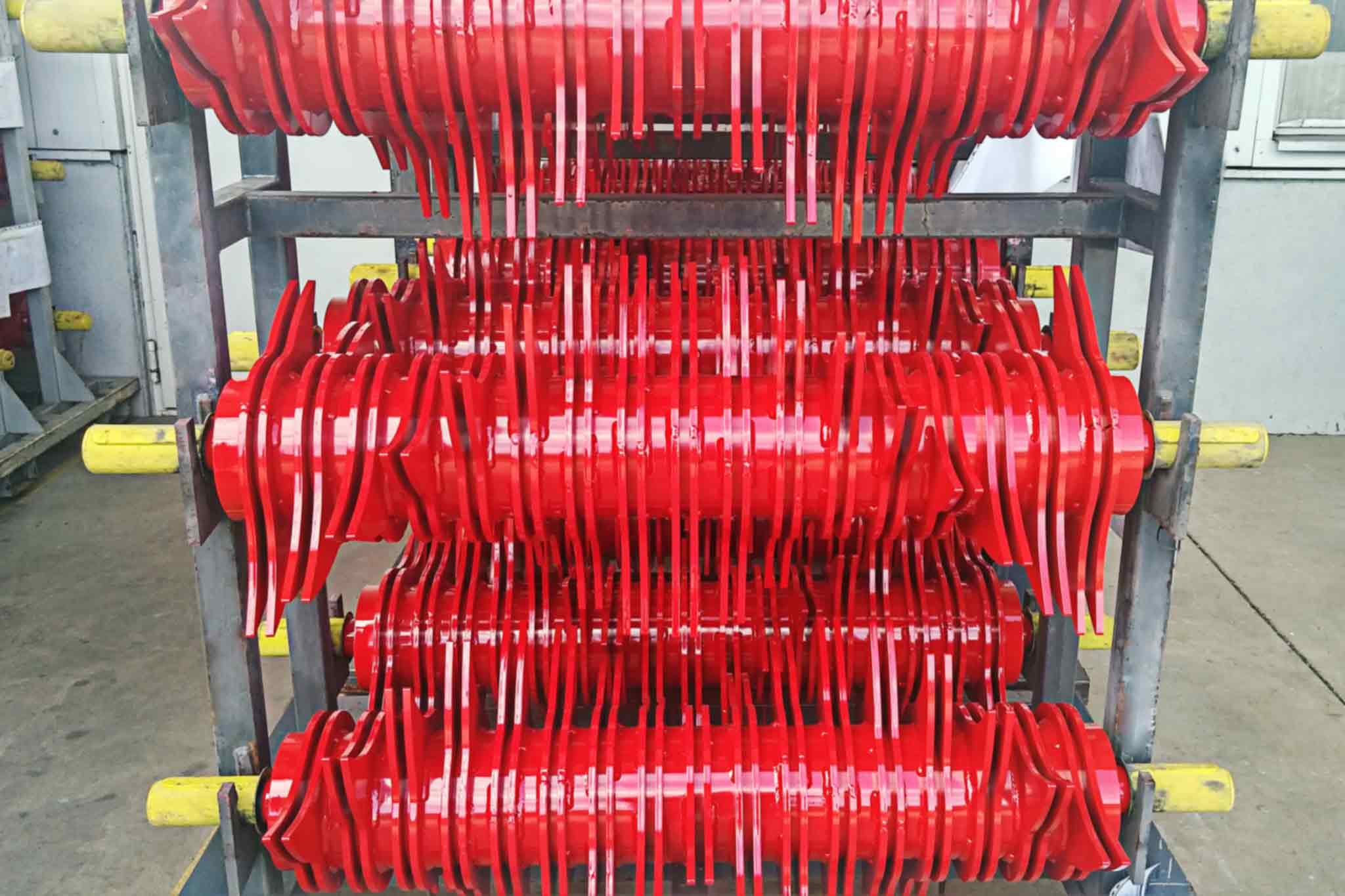

The products currently being manufactured are a dozen components that the customer requires for the construction of straw bale presses. Bühring generally delivers the components ready for installation, i.e. completely machined, welded and painted. One of these components is a rotor with 17 welded double rings each with two spikes that within a round baler is responsible for the optimum transport of the straw from the pick-up system to the straw bale press.

The basic body of the rotor:

- Made from thin-walled roller tube made of steel

- 1,200 mm long

- Diameter of 250 mm

MAPAL provides a suitable machining process

The surface quality required for the order – a roughness of Rz 25 μm must not be exceeded – is achieved without problem using the new machining concept. The main times vary depending on the machining task from a few seconds to a few minutes. “We can produce more precisely and efficiently with the new machine and the MAPAL tools”, says Sven Bühring. “And we have not yet optimised programming due to a lack of time so we expect further improvements in the future.”

Machine capacity freed up for new applications

Bühring receives optimum support for its expansion from MAPAL’s technical support team that the company has come to value. “When teething troubles of the machine contaminated the hydraulic drive system of the facing head in the commissioning phase, an employee from MAPAL was on site the next morning, picked up the faulty part and took care of everything else without complication. This is decisive because we must have products ready at short notice for many customers. Here we have to look for technology partners like MAPAL who we can rely on completely.”

“Without a wide range of production techniques and a high availability of production equipment, a toll manufacturer does not have any future prospects. Reliable and tailored machining solutions and an efficient technical support like the one from MAPAL are an important part in having continual success.”