Industrie aéronautique: Outils PCD - De nouvelles solutions pour les pièces de structures en composite et en aluminium

sont fabriquées en alliages d'aluminium ou en matériaux composites, voir d'une

combinaison des deux. Il s'agit ici de prévenir l'usure par fatigue des matériaux

tout en cherchant à alléger les structures.

La fiabilité des procédés est un élément central de l'usinage des pièces destinées à

l'industrie aéronautique et spatiale. Les outils PCD (Diamant Polycristallin) MAPAL

répondent complètement à ces exigences et se caractérisent par une durée de vie

élevée et de très bons résultats d'usinages.

Durée de vie Améliorée de 60 % pour le perçage des matériaux composites

Dans la construction aéronautique, des milliers de trous pour les assemblages rivetés doivent être percés dans des composants et des matériaux composites. En règle générale, des forets en carbure monobloc revêtus diamant sont utilisés. Toutefois, ces forets ne sont pas adaptés à toutes les applications spécifiques. En effet, certaines utilisations extrêmes nécessitent de repousser les limites et impliquent des durées de vie supérieures, une fiabilité des processus maximale et une qualité de perçage irréprochable.

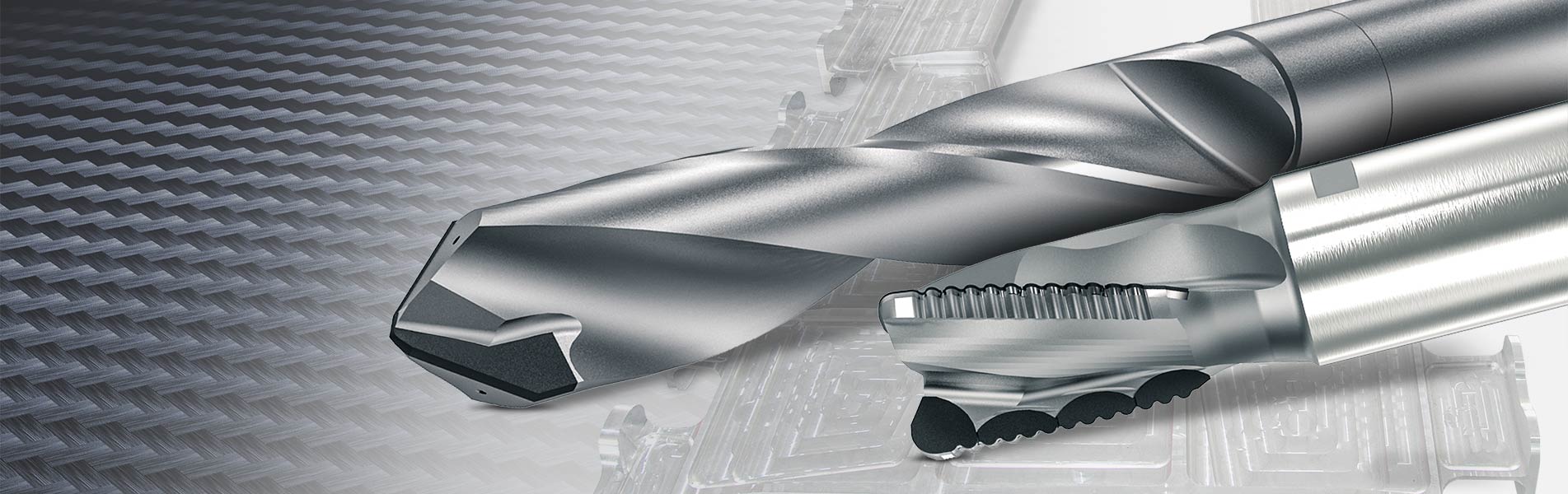

MAPAL a développé un nouveau foret PCD pour l'usinage des matériaux composites, comme le CFRP (plastique renforcé de fibres de carbone) et les matériaux composites multicouches en aluminium et fibre de carbone, utilisé pour l'assemblage. Le foret se caractérise notamment par son arête de coupe continue en PCD. Jusqu'à présent, seul le haut de l’arrête était en PCD, le centre restait quant à lui en carbure. Toutefois, l'interruption de l'arête de coupe était source d'instabilité au niveau des transitions et la brasure dans l'interstice avait tendance à s'user rapidement. Avec ce nouvel outil, MAPAL a remédié au problème d'instabilité.

L'arête de coupe PCD, polie des deux côtés, est insérée dans le corps de l'outil en carbure monobloc. Cela rend l'ensemble beaucoup plus stable. Grâce a l'angle de pointe de 115°, le foret est auto-centrant. L'angle de pointe secondaire de 80° assure une sortie d’alésage

sans délaminage.

Ce foret fait la différence chez les clients grâce à sa fiabilité et à sa grande durée de vie. Sur une pièce pour hélicoptère, des trous sont percés pour recevoir des éléments de fixation. La pièce en question comporte une couche de fibre de carbone renforcée de 50 mm. L'outil qui était utilisé auparavant avait atteint sa fin de vie après 50 perçages. Désormais, avec des conditions de coupe plus élevées et un perçage de meilleur qualité, le foret PCD de MAPAL permet au client de réaliser plus de 80 perçages d'un diamètre de 19 mm, soit une augmentation de 60 % par rapport aux outils PCD de conception classique.

Fraise d'ébauche PCD pour l'usinage à sec

Lors de l'usinage des pièces de structure aéronautique en aluminium une grande partie de la matière est enlevée par usinage. Pour l'usinage d'ébauche des évidements ou des poches à l'intérieur de l'aile, MAPAL propose dans sa gamme de produit, l'OptiMill-SPMRough, une fraise en carbure monobloc qui a largement fait ses preuves. Toutefois, ces fraises d'ébauche ne sont utilisées qu'en usinage avec arrosage. Cela est dû au fait que les outils en carbure monobloc atteignent leurs limites lors de l'usinage à sec des alliages d'aluminium à copeaux longs, comme c'est le cas dans la construction aéronautique. En effet, des arêtes rapportées se forment très rapidement et les outils sont soumis à une usure beaucoup trop importante.

La demande croissante s'oriente donc vers un outil d'usinage a sec afin d’éviter que les évidements et les poches ne se remplissent de liquide de coupe. C'est ce que MAPAL propose aujourd'hui avec une nouvelle fraise à insert PCD.

La géométrie de la nouvelle fraise est, à bien des égards, identique à celle de son équivalent en carbure monobloc. La géométrie d'ébauche à profil rond, spécialement développée, garantit une coupe douce et réduit les efforts de coupe. En outre, elle confère à l'outil d'excellentes capacités en plongée. Le transfert thermique vers la pièce est minime.

Grâce à la durée de vie significativement plus longue de l'outil PCD lors de l'usinage à sec

des alliages d'aluminium à copeaux continus par rapport à l'outil équivalent en carbure monobloc, son utilisation s'avère beaucoup plus économique. Le coût plus important de l'outil est donc rapidement amorti.