Reconditioning to original quality results in major savings

Investing in long tool lives with maintenance services from MAPAL

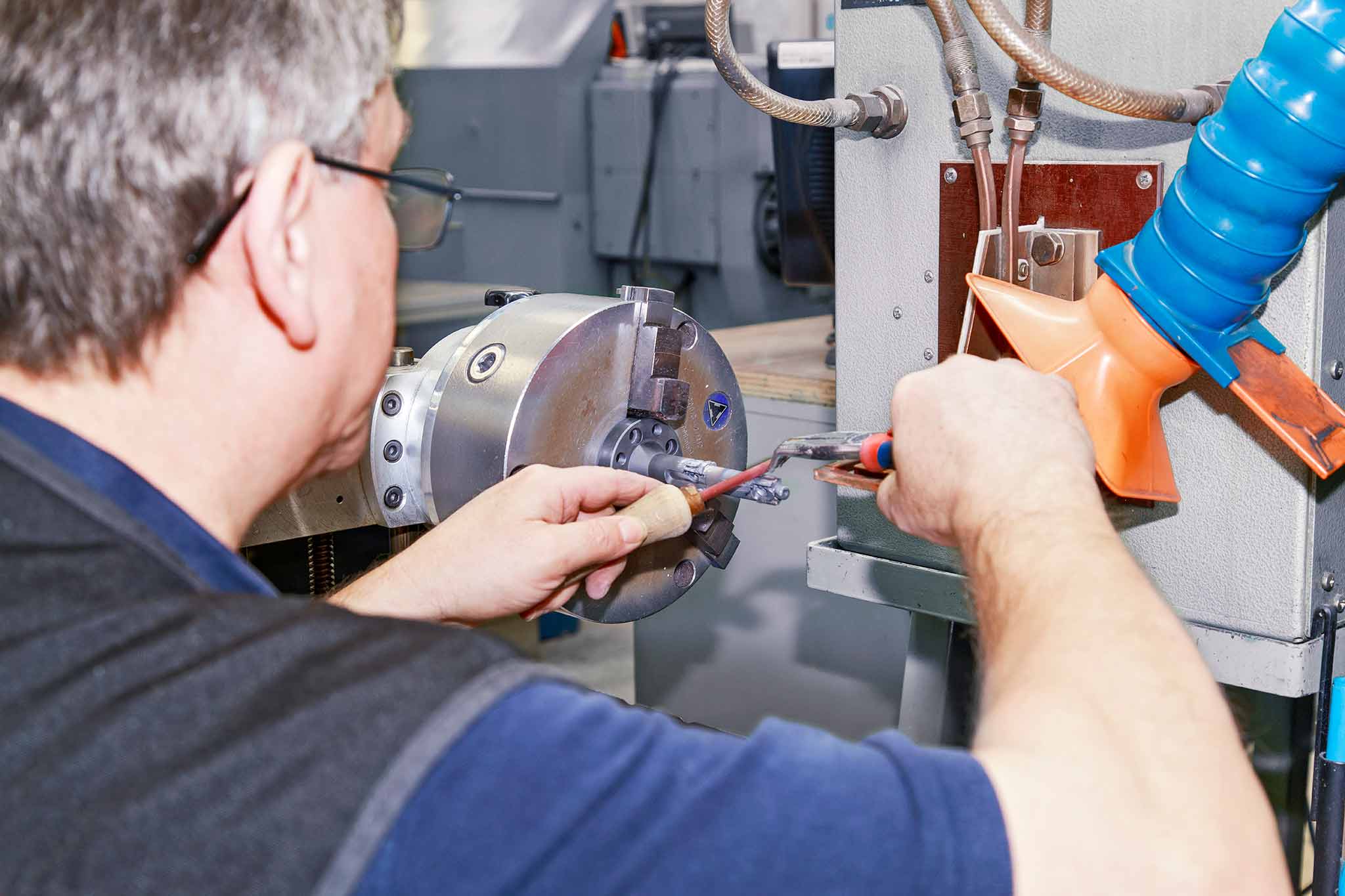

With regard to the maintenance of precision tools, MAPAL offers a broad range of options: from reconditioning of individual tools to a complete maintenance contract for specific tools and devices. Reconditioning services is available for MAPAL tools as well as for tools from other manufacturers. As part of the repair service, MAPAL specialists also repair tool bodies that are damaged due to chipping or erosion, or that have a damaged insert seat. Upon request customers receive a measurement report that documents the precision and performance of the reconditioned tools.And to ensure maximum precision in the setting room, MAPAL also takes over the inspection and maintenance of mechanical or electronic actuating tools, setting and measuring devices. Telephone support and remote maintenance for MAPAL tool dispensing systems complement the maintenance services.

Initial situation: the customer's demand

Service modules maintenance

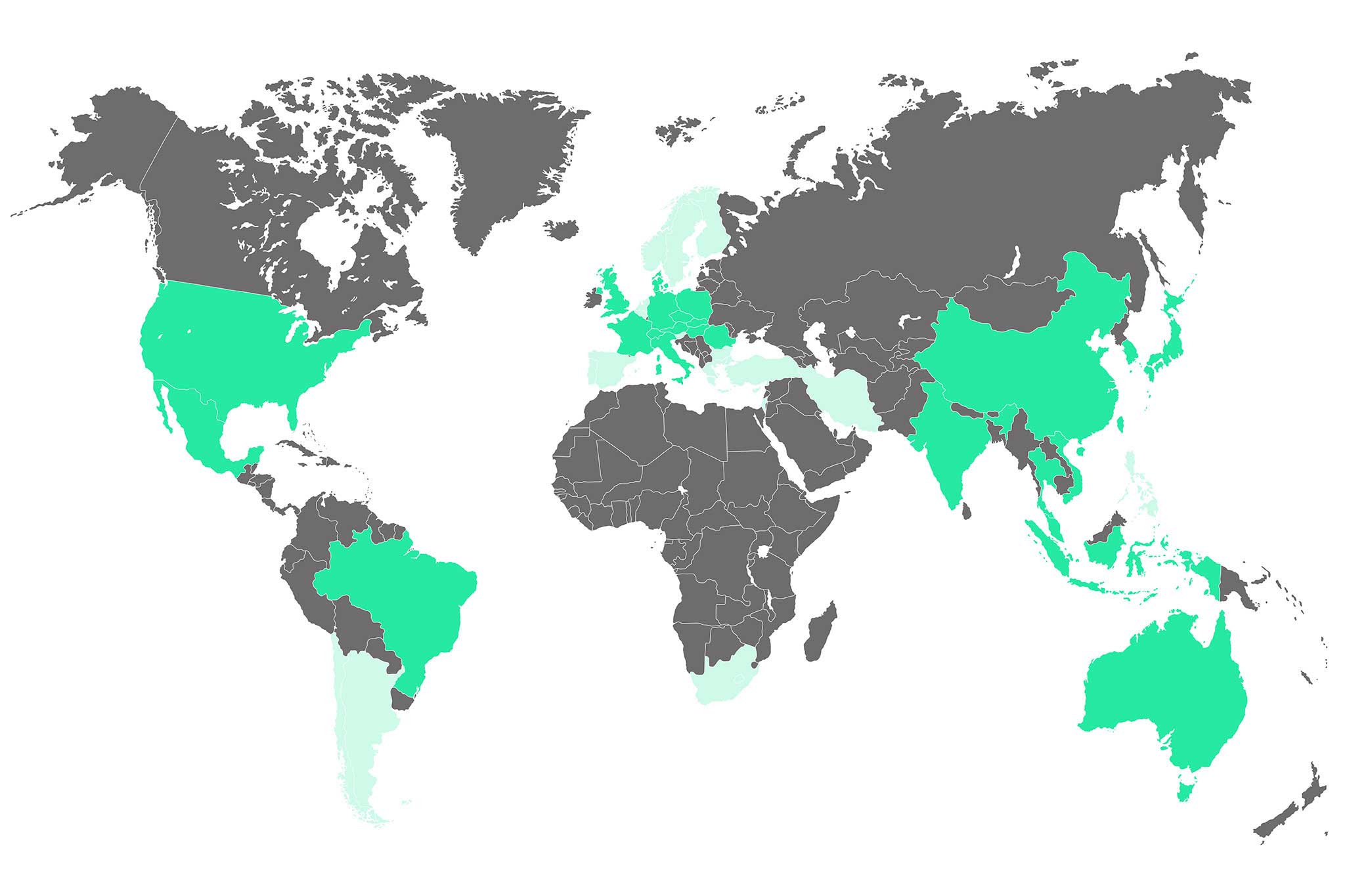

Maintenance services worldwide

Irrespective of where the customers produce in the world: They can be certain to profit on-site from the MAPAL services for maintenance and reconditioning.

High-quality, consistent, fast.