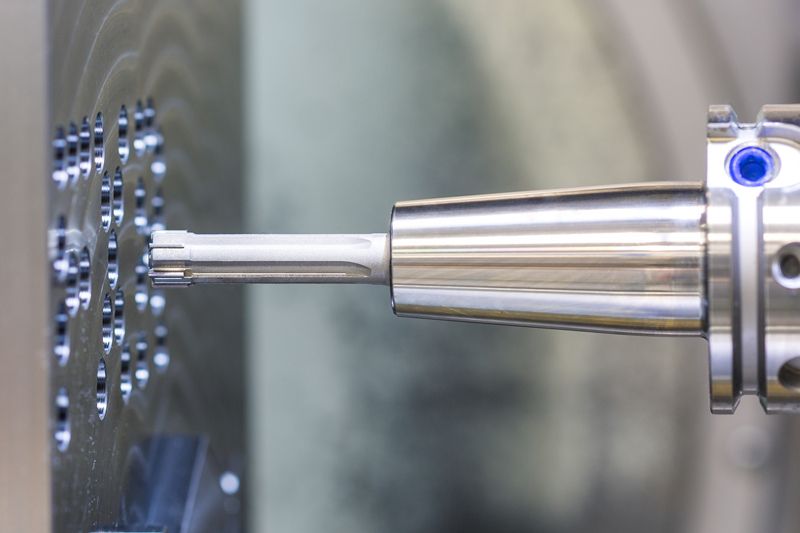

FixReam 700

Significantly reduced cost per part thanks to reconditioning

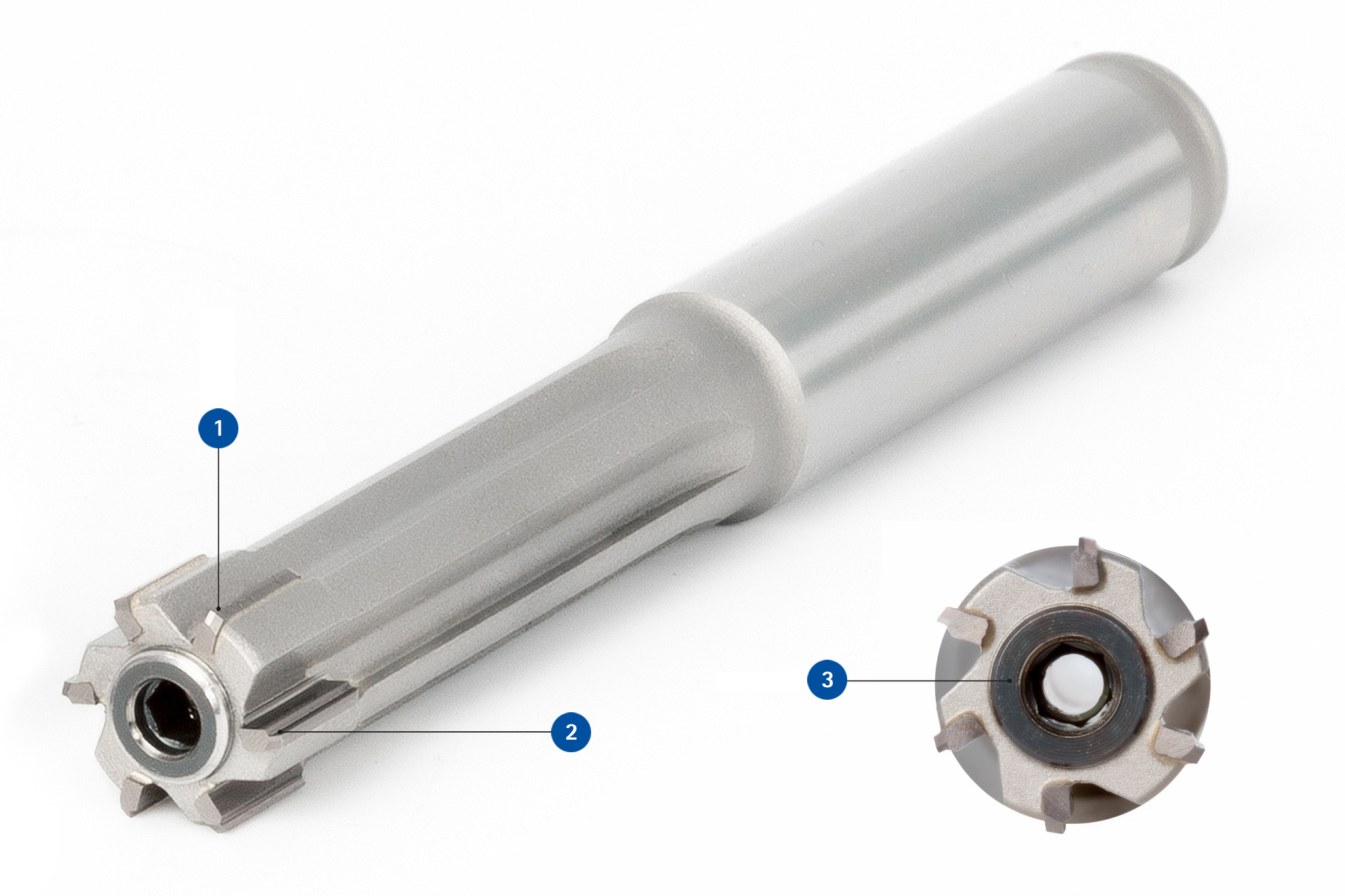

FixReam 700 reamers are a particularly sustainable tool. The distinctive feature of the cylindrical shank reamers with brazed cutting edges is their frequent reusability, achieved by replacing the cutting edges and regrinding. A tool can be reground up to twice before new cutting edges need to be brazed in. Afterwards, two further regrinds, another change of cutting edges and two further regrinds are possible. Thus a reamer provides nine tool lives. During servicing, the manufacturer expands the tool slightly with an expansion screw and can thus regrind all functional surfaces, i.e. the lead and diameter. Compared with a tool without an expansion function, tool costs can be reduced by up to 15 per cent.

MAPAL has developed and patented new geometries specifically for these reamers. As a result, users achieve up to 30 per cent better roundness and cylindrical form as well as improved chip evacuation compared with other cylindrical shank reamers.

FixReam 700 reamers are available in two variants for through holes and blind holes with uncoated, wear-resistant cermet cutting edges for machining steel and cast materials. In addition, PVD-coated cutting materials and lead geometries are available for use in stainless steels, non-ferrous metals and difficult-to-machine materials.

They are typically available in two lengths as a short or long version. The tools can be configured within a diameter range from 9.9 to 32.2 mm.

Suitable for all material groups

Features

- PVD coating: High level of hardness and resistance to wear

- Optimal chip formation: Thanks to new, innovative leads

- Expansion screw for compensation: Allows up to 9 tool uses

- Patented geometry: 30% better roundness and cylindrical form