TOOLTRONIC 和车端面刀头

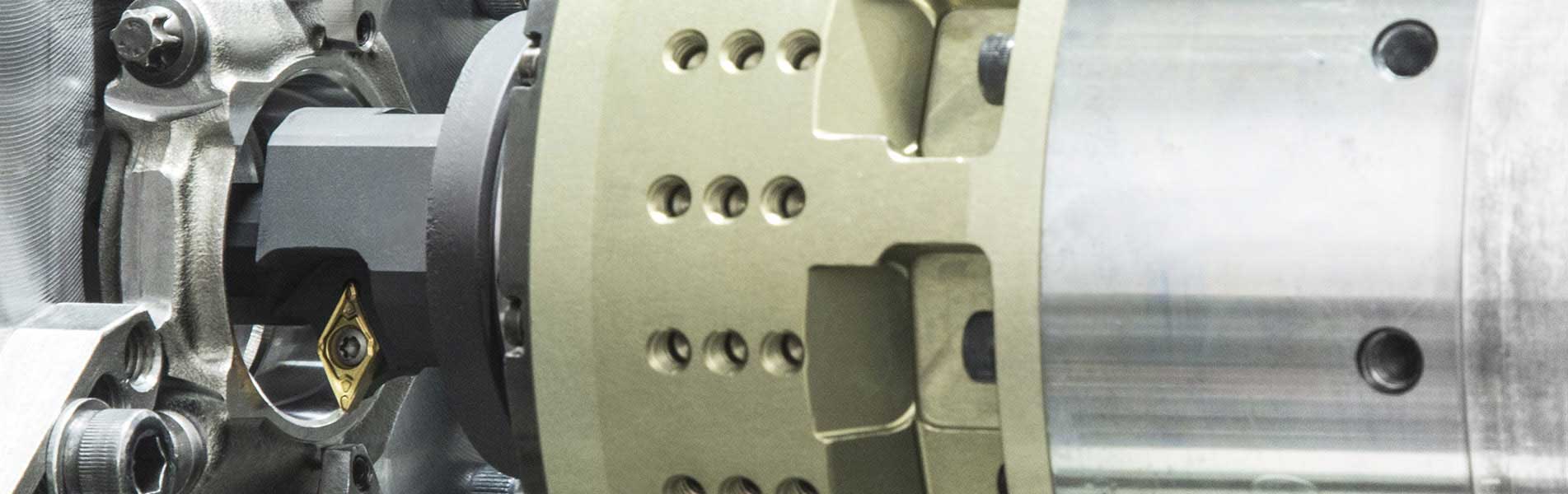

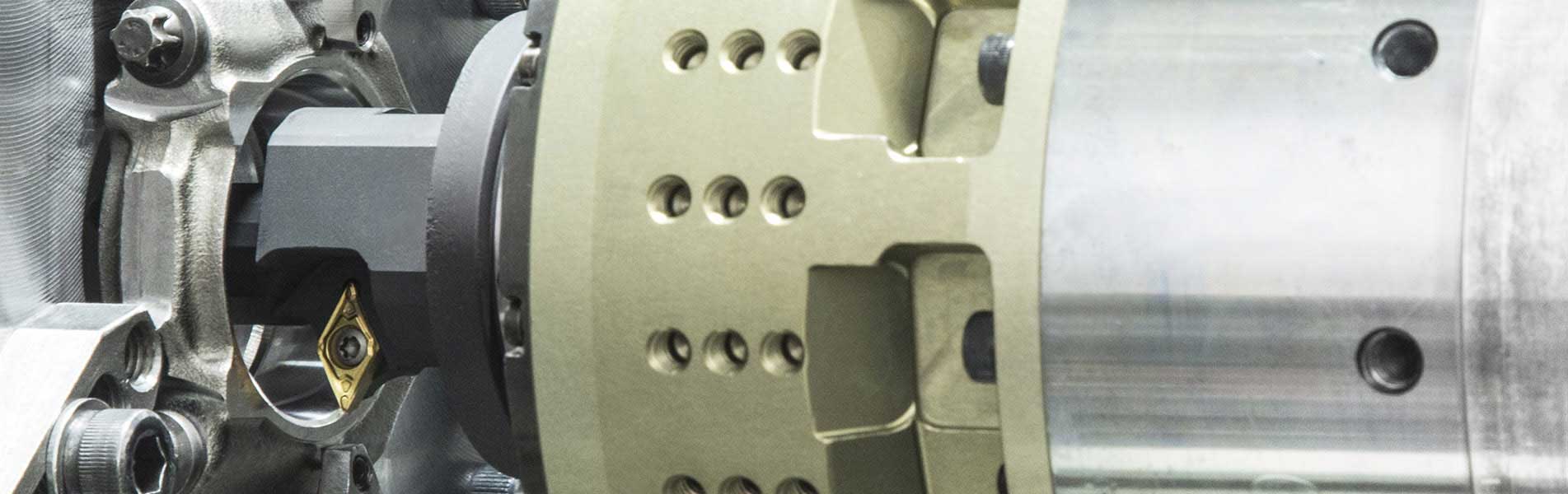

TOOLTRONIC – 适用于加工多样化和具有高度灵活性的、应用在加工中 心和特殊机床上的通用型驱动器。用于加工中心的 TOOLTRONIC 是一种 完整的可更换的刀具轴,其应用范围极为广泛。

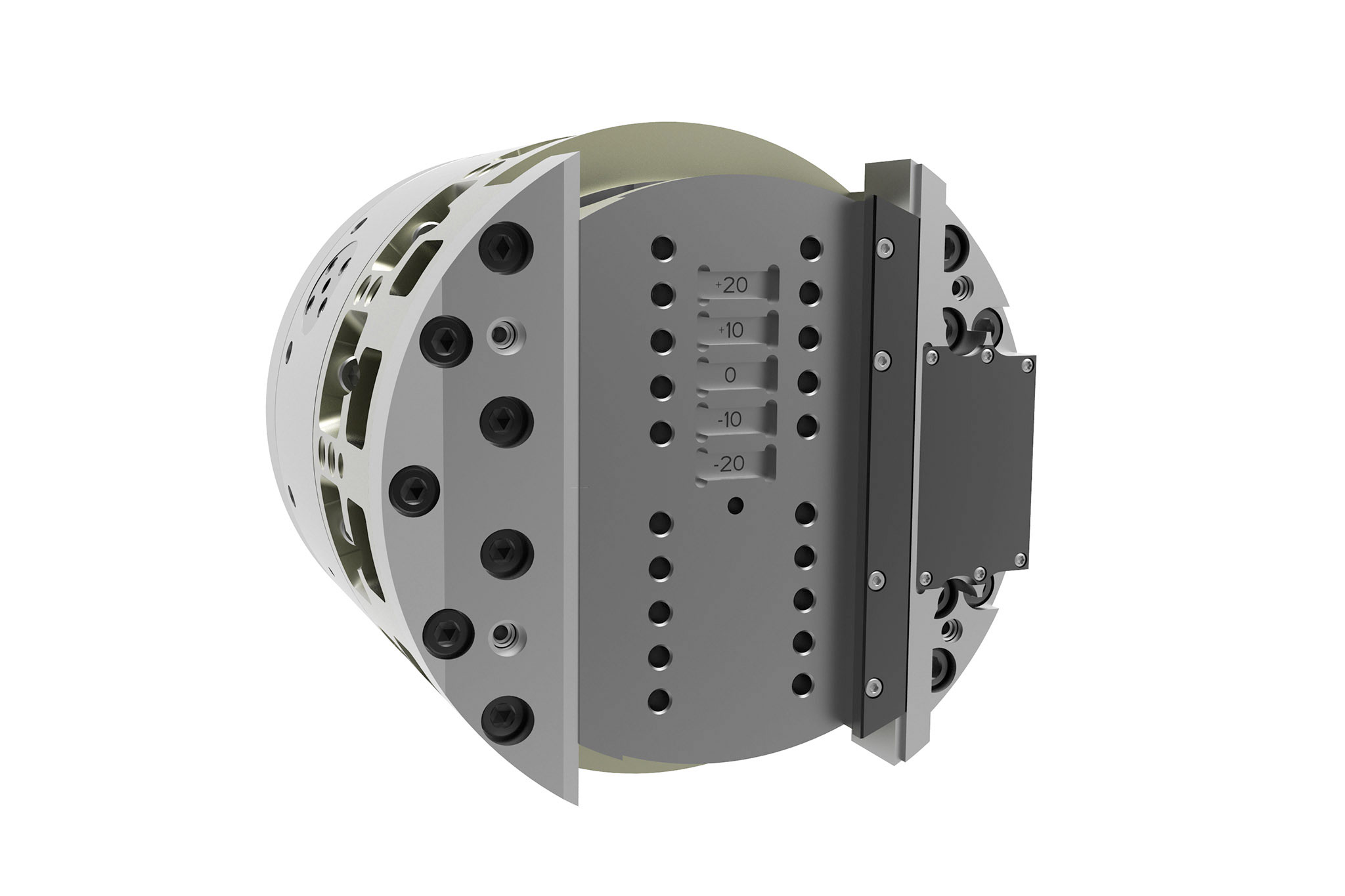

用于车端面、切槽和轮廓加工的车端面刀头主要应用在进行大系列加工 的特殊机床上。这种滑块式刀具的操作以及刀具夹头和刀片的展开式控 制由一个 NC 控制式横进给装置完成,它安装在主轴驱动器上或者安装 在进给单元的背面。

用于车端面、切槽和轮廓加工的车端面刀头主要应用在进行大系列加工 的特殊机床上。这种滑块式刀具的操作以及刀具夹头和刀片的展开式控 制由一个 NC 控制式横进给装置完成,它安装在主轴驱动器上或者安装 在进给单元的背面。

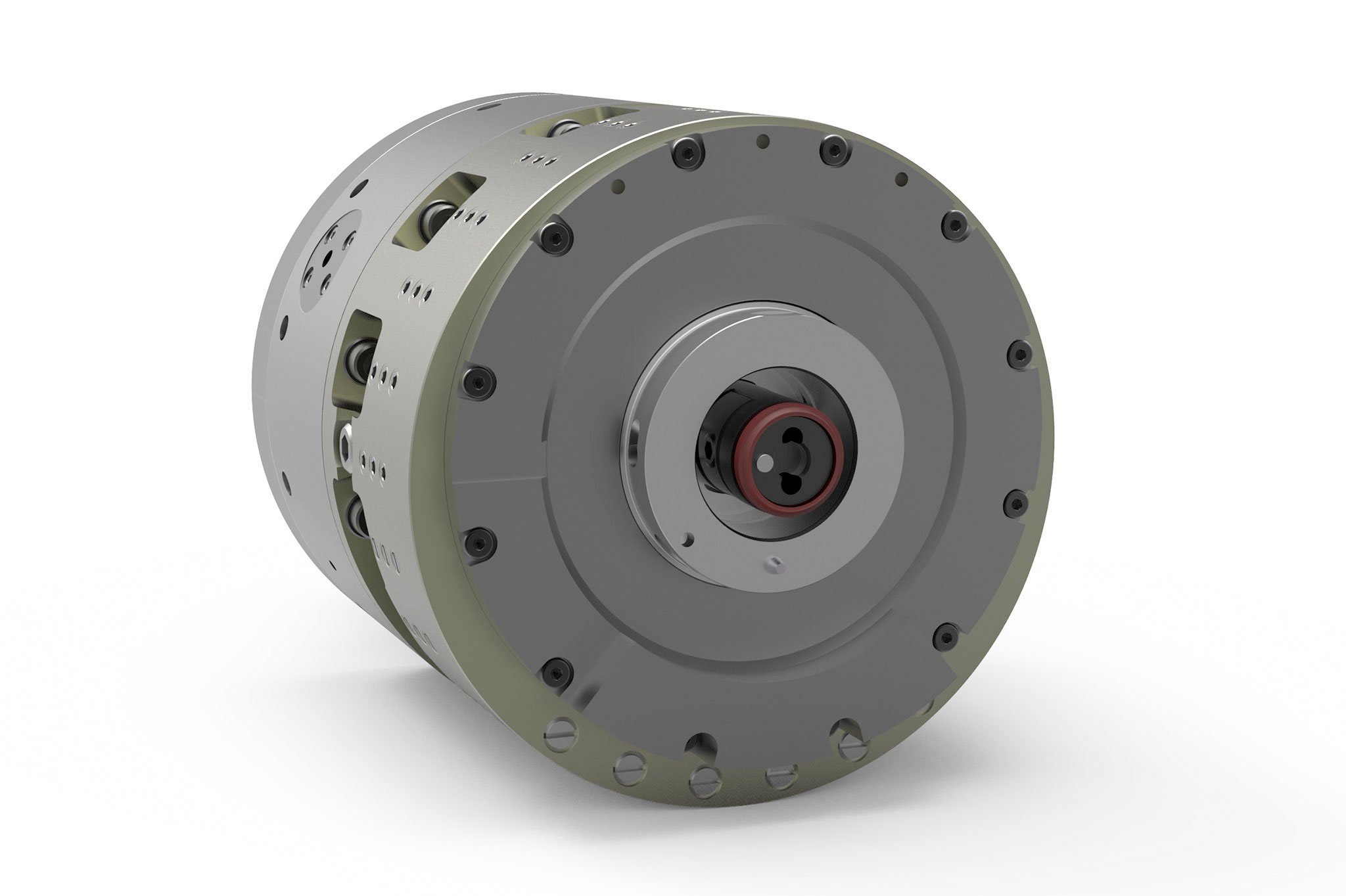

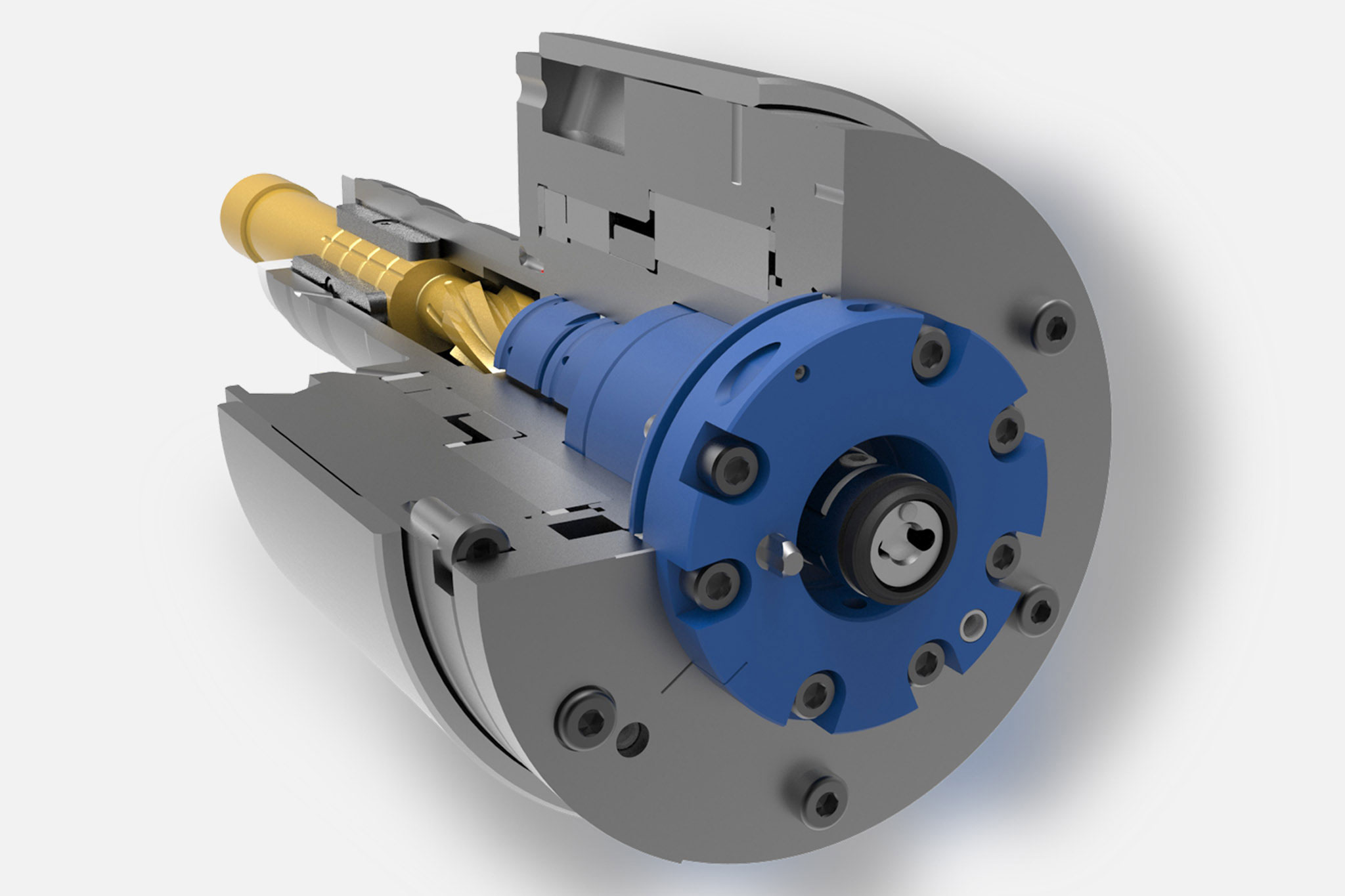

机电一体化的刀具系统——TOOLTRONIC

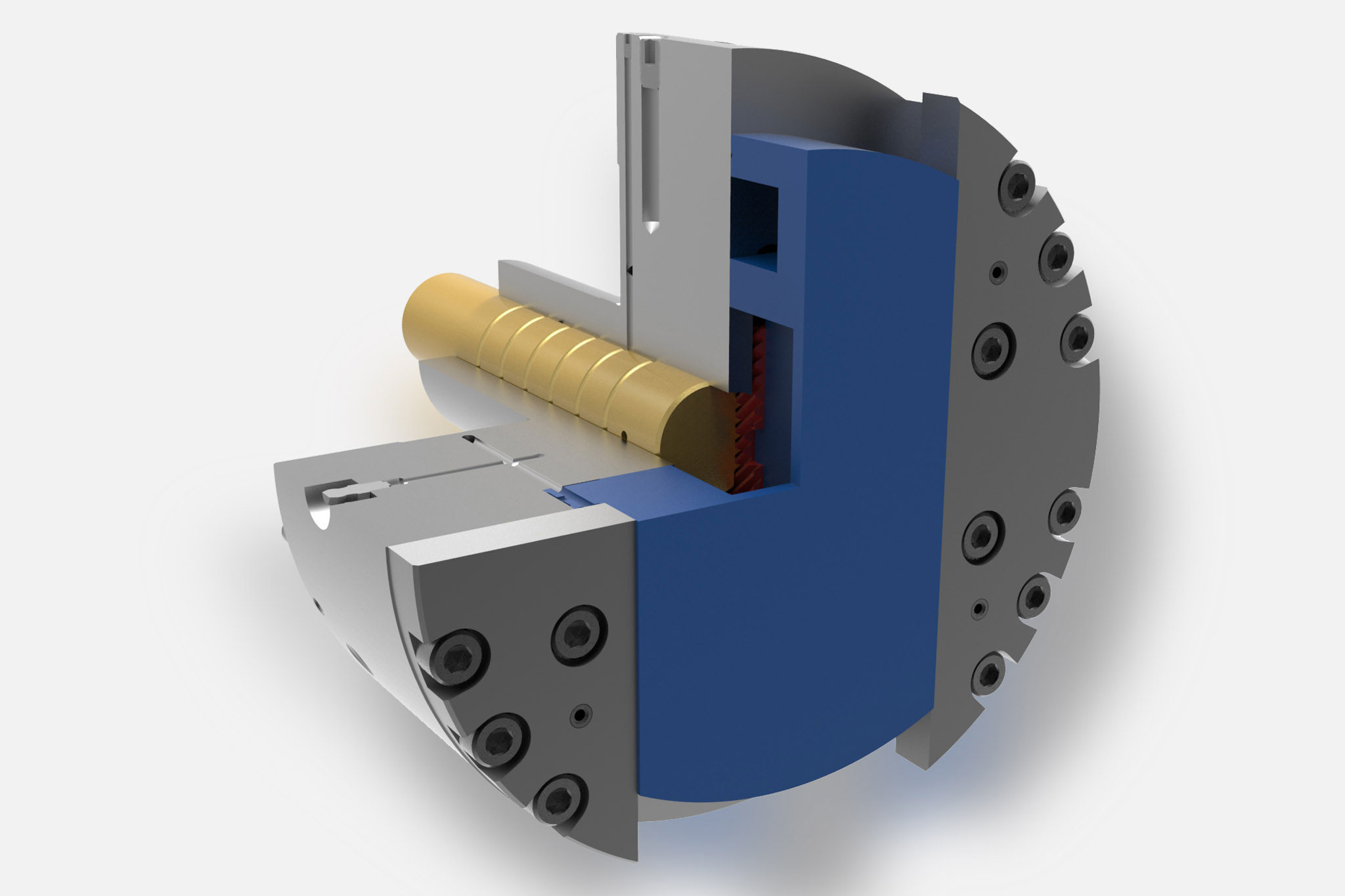

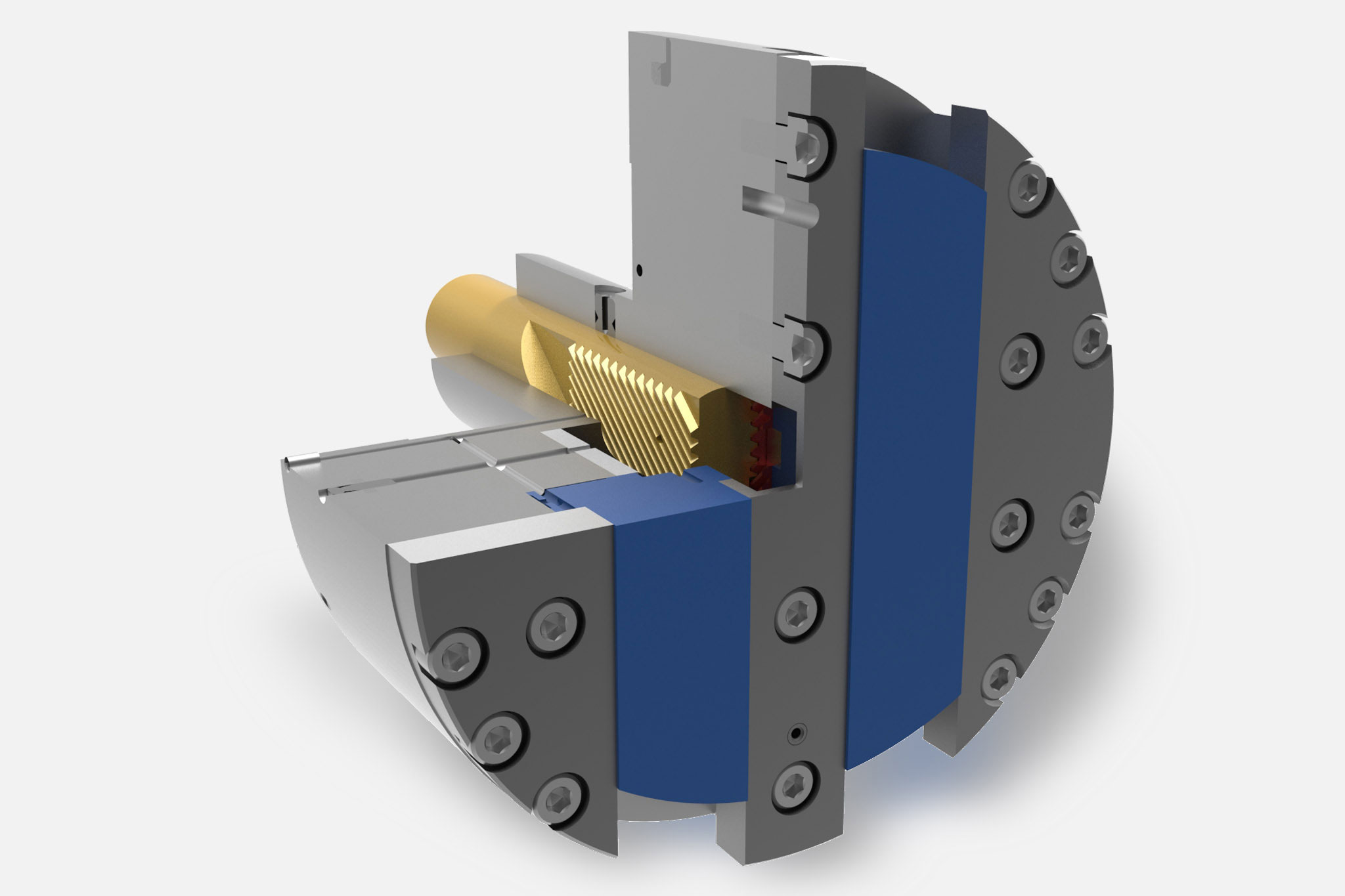

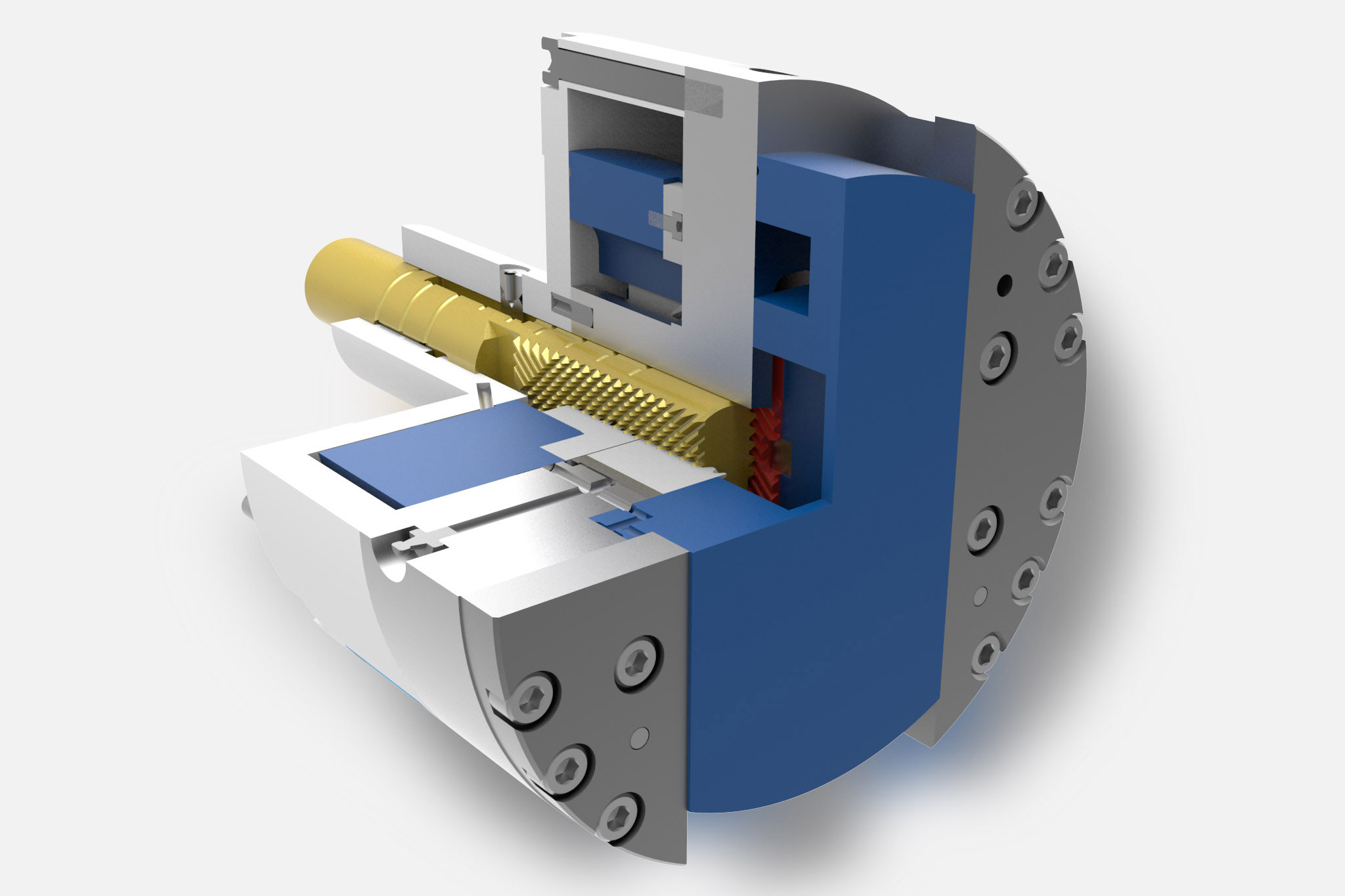

无论是在加工中心还是在特种机床上配置该机电一体化刀具系统——TOOLTRONIC都可以轻松并且可靠地实现修光加工运行。无论是加工轮廓、背面铲槽以及非圆柱形孔,都可以和闭合调节循环一样进行切削刃补偿,或者对于变化多端的零件家族,实现快捷的加工制造。

独立的驱动模块,通过其感应式的能量-和双向数据传输,成为了一个完整的NC-轴,并且已经集成到了上一层机床控制系统中。这意味着现代CNC-控制系统的全部功能,也可以和TOOLTRONIC-刀具系统完美结合,进行一体化应用。

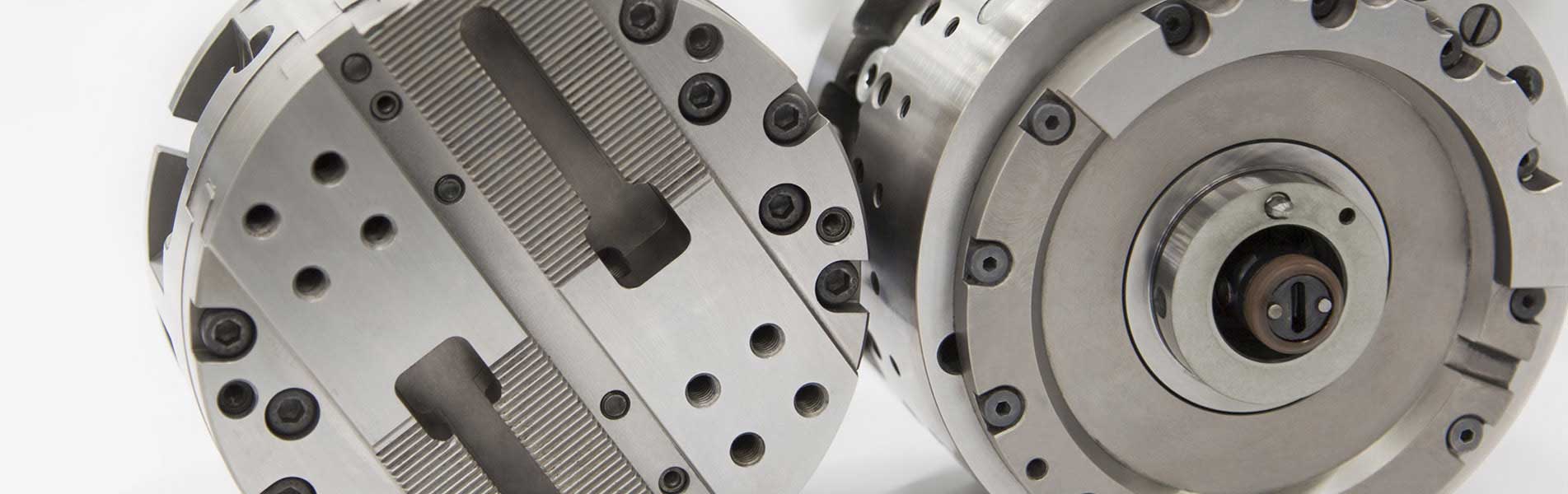

根据不同的加工任务,MAPAL公司在TOOLTRONIC的模块化接口上,设置有各种不同的端面旋转头(从动轴)。作为标准配置,将提供偏心的修光刀具(EAT)。对于那些在特定转速下需要较大行程的应用情形,可以借助直线修光刀具(LAT)完成加工。

独立的驱动模块,通过其感应式的能量-和双向数据传输,成为了一个完整的NC-轴,并且已经集成到了上一层机床控制系统中。这意味着现代CNC-控制系统的全部功能,也可以和TOOLTRONIC-刀具系统完美结合,进行一体化应用。

根据不同的加工任务,MAPAL公司在TOOLTRONIC的模块化接口上,设置有各种不同的端面旋转头(从动轴)。作为标准配置,将提供偏心的修光刀具(EAT)。对于那些在特定转速下需要较大行程的应用情形,可以借助直线修光刀具(LAT)完成加工。

车端面刀头

用于车端面、切槽和轮廓加工的车端面刀头主要应用在进行大系列加工 的特殊机床上。这种滑块式刀具的操作以及刀具夹头和刀片的展开式控 制由一个 NC 控制式横进给装置完成,它安装在主轴驱动器上或者安装 在进给单元的背面。