Große Einsparungen durch Wiederaufbereitung in Originalqualität

Investition in ein langes Werkzeugleben mit MAPAL Maintenance-Services

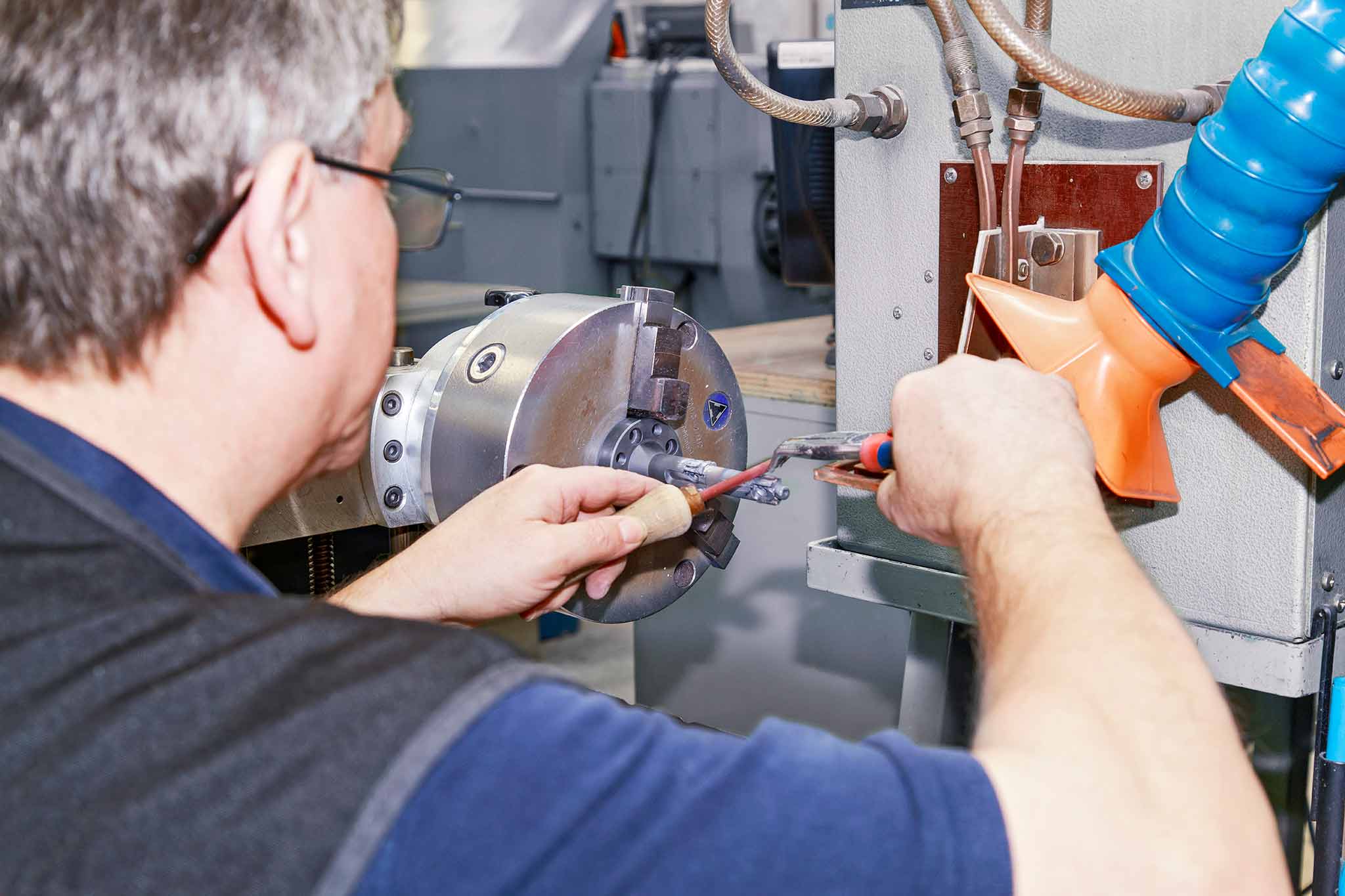

Wenn es um die Instandhaltung von Werkzeugen geht, stehen mit MAPAL alle Möglichkeiten offen: Von der Wiederaufbereitung einzelner Werkzeuge bis zu kompletten Wartungsverträgen für bestimmte Werkzeuge und Geräte. Der Wiederaufbereitungsservice steht für MAPAL Werkzeuge genauso wie für Werkzeuge anderer Hersteller zur Verfügung. Im Rahmen des Reparatur-Services setzen MAPAL Spezialisten auch beschädigte Werkzeuggrundkörper mit Ausbrüchen, Auswaschungen oder beschädigtem Plattensitz instand. Auf Wunsch erhalten die Kunden jeweils ein Messprotokoll, das die Präzision und Leistungsfähigkeit der wiederaufbereiteten Werkzeuge dokumentiert.Und damit auch im Einstellraum stets für höchste Präzision gesorgt ist, bietet MAPAL auch die vorbeugende Inspektion und Wartung der mechanischen oder elektronischen Aussteuerwerkzeuge, Einstell- und Messgeräte an. Für MAPAL Werkzeugausgabesysteme stehen ein telefonischer Support und Fernwartung zur Verfügung.

Ausgangssituation: Der Bedarf des Kunden

Servicebausteine Maintenance

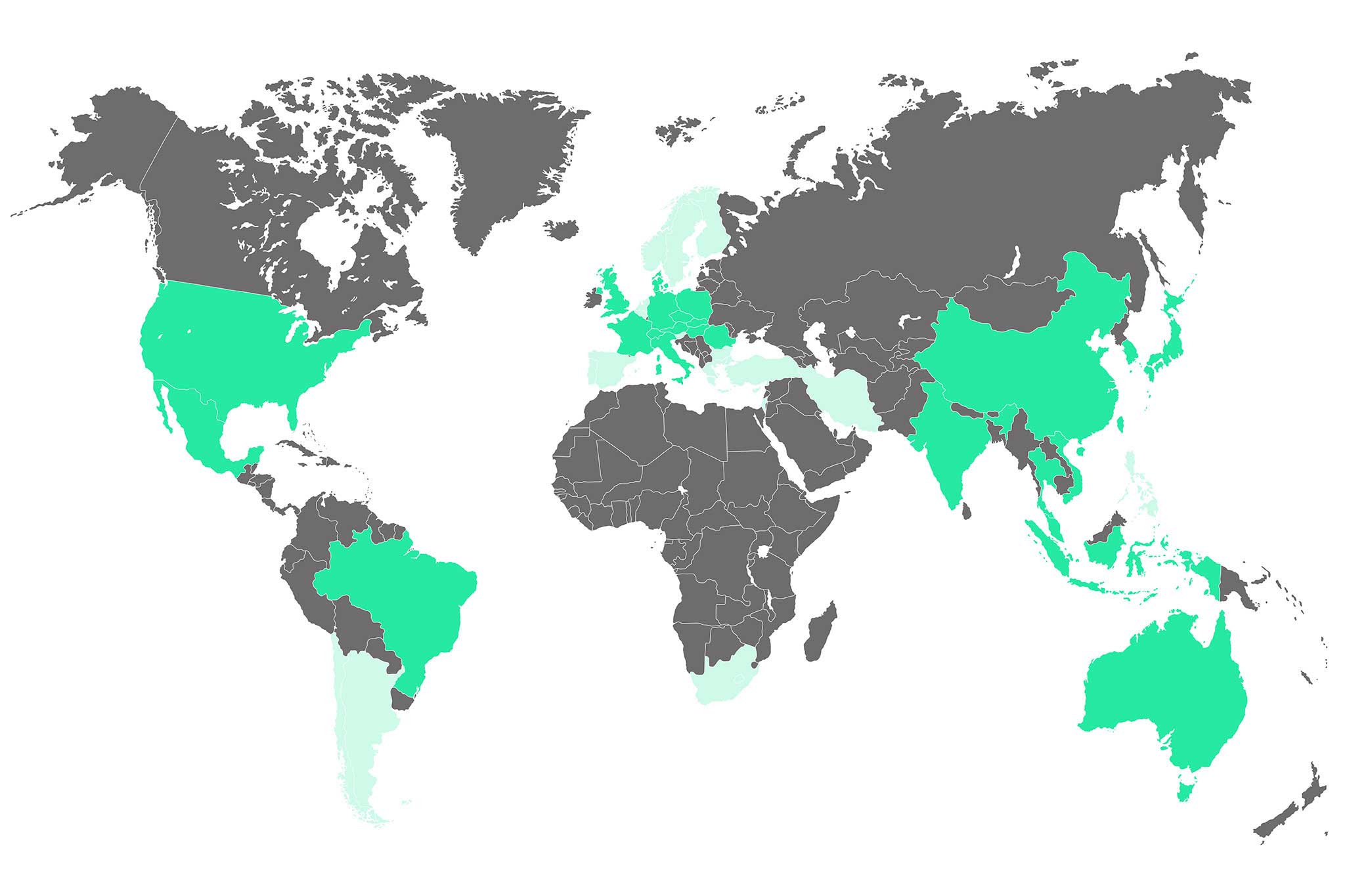

Maintenance-Services weltweit

Egal, wo auf der Welt die Kunden produzieren: Sie können sicher sein, dass sie vor Ort die MAPAL Services zur Instandhaltung und Wiederaufbereitung erhalten.

Hochwertig, einheitlich, schnell.