Großserie mit festen und justierbaren Werkzeugen

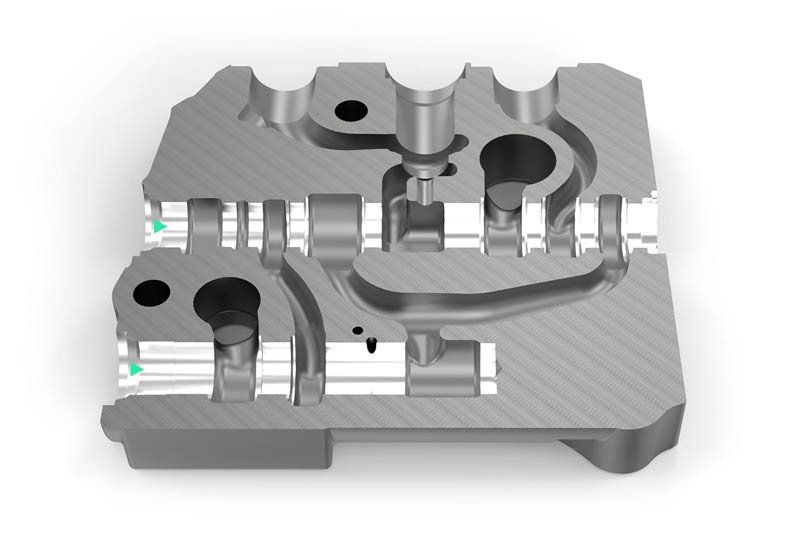

Ventilgehäuse EN-GJS-400-15 – Schieberbohrung und Druckwaagenbohrung

Ausgangssituation beim Kunden

- Großserie

- Werkzeugeinstellung gewünscht

- Hohe Maschinenstundensätze

- Hohe Kosten für nachfolgendes Dornhonen

Besonderheiten der Lösung

- Ideal aufeinander abgestimmte Einzelwerkzeuge garantieren optimale Vorbedingungen für einen reduzierten Honprozess

- Honprozess kann bei bestimmten Bauteilanforderungen eliminiert werden

Schieberbohrung

1. Aufbohren

- Optimale Resultate der Vorbearbeitung durch einen abgestimmten Pilotier- und Aufbohrprozess

- Optimaler Spanfluss und erweiterte Nachschliffmöglichkeiten durch Mehrfasentechnologie und perfekte Kühlmittelführung

- Vermeidung von Ringbildung in den Hohlräumen durch spezielle Aufbohrgeometrie → Kosten für Entfernung der Ringe entfallen

2. Steuerkantenbearbeitung

- VHM-Profilwerkzeug

- Höchste Genauigkeit und Oberflächengüte der Steuerkanten

- Definierte Steuerkanten ohne Ausbrüche

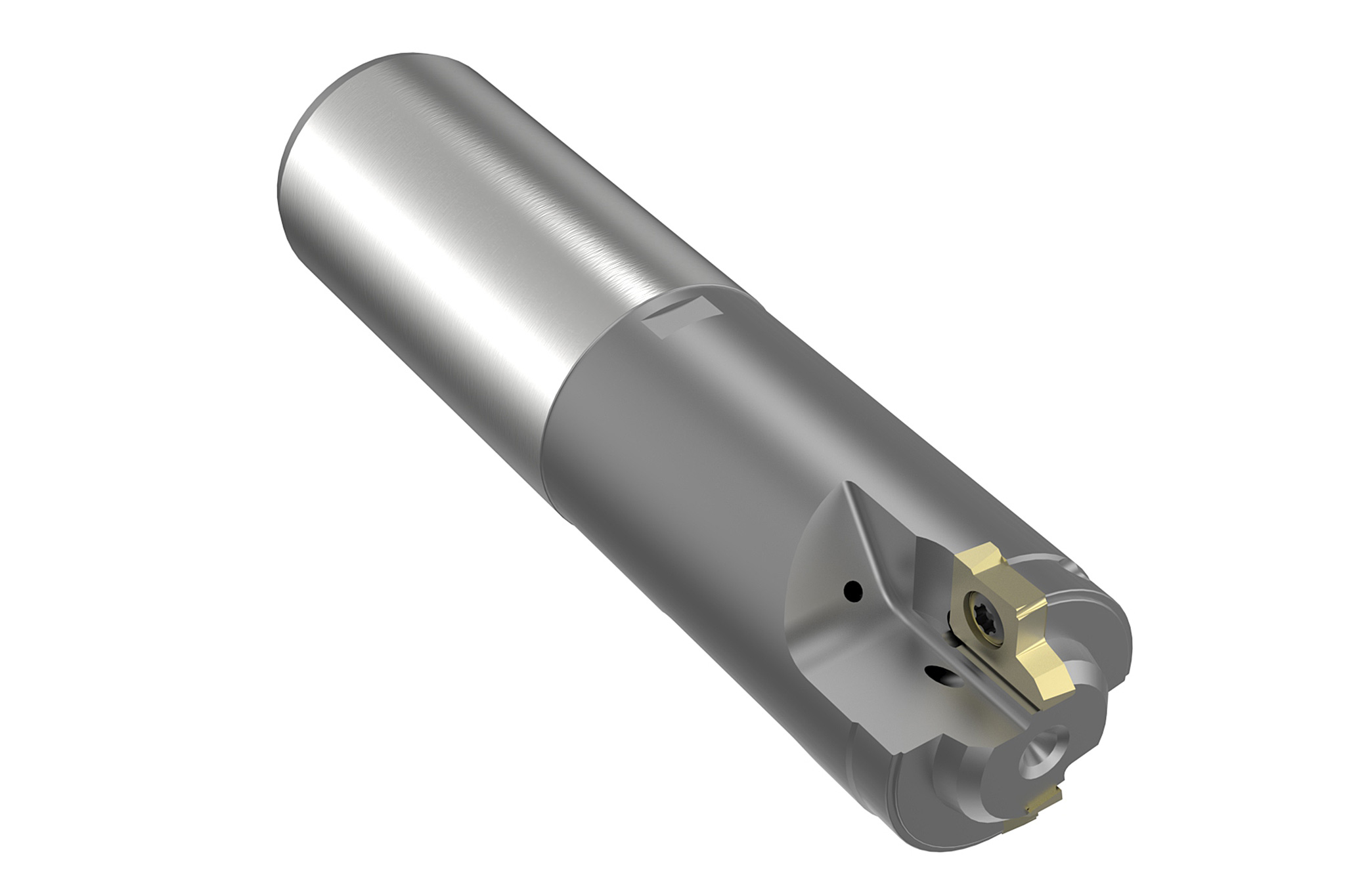

3. Feinbohren

- Feinbohrwerkzeug mit EasyAdjust-System und Führungsleisten

- Prozesssichere Feinbearbeitung mit einfachem Handling

- Beste Zylinderformen durch ideale Nachführung

Druckwaagenbohrung

1. Aufbohren

- VHM-Aufbohrwerkzeug mit 6 Führungsfasen und spezieller Anschnittgeometrie

- Gerade Bohrung, idealer Spanfluss und Führung über die gesamte Bohrungslänge

- Reduzierung der Nebenzeiten durch zwei Bearbeitungen in einem Werkzeug

2. Konturbearbeitung

- Zweischneidiges Aufbohrwerkzeug mit Formschneiden

- Prozesssichere Bearbeitung der Kontur

- Einfaches Handling bei geringen Schneidstoffkosten

3. Feinbohren

- Feinbohrwerkzeug mit EasyAdjust-System und Führungsleisten

- Prozesssichere Feinbearbeitung mit einfachem Handling ohne nachfolgendes Honen

- Beste Zylinderformen durch ideale Nachführung

Vorteile

- Teurer Honprozess in der Schieberbohrung verkürzt

- Geringe Werkzeugkosten pro Bohrung

- Kürzere Nebenzeiten durch cleveres Engineering in Zusammenarbeit mit dem Kunden

- Signifikante Kosteneinsparung durch Wegfall des Honprozesses in der Druckwaagenbohrung

![JÄHRLICHE HERSTELLKOSTEN DER DRUCKWAAGENBOHRUNG [€]](/medias/sys_master/root/h6a/h71/9043460653086/Grafiken_DE-13/Grafiken-DE-13.jpg)