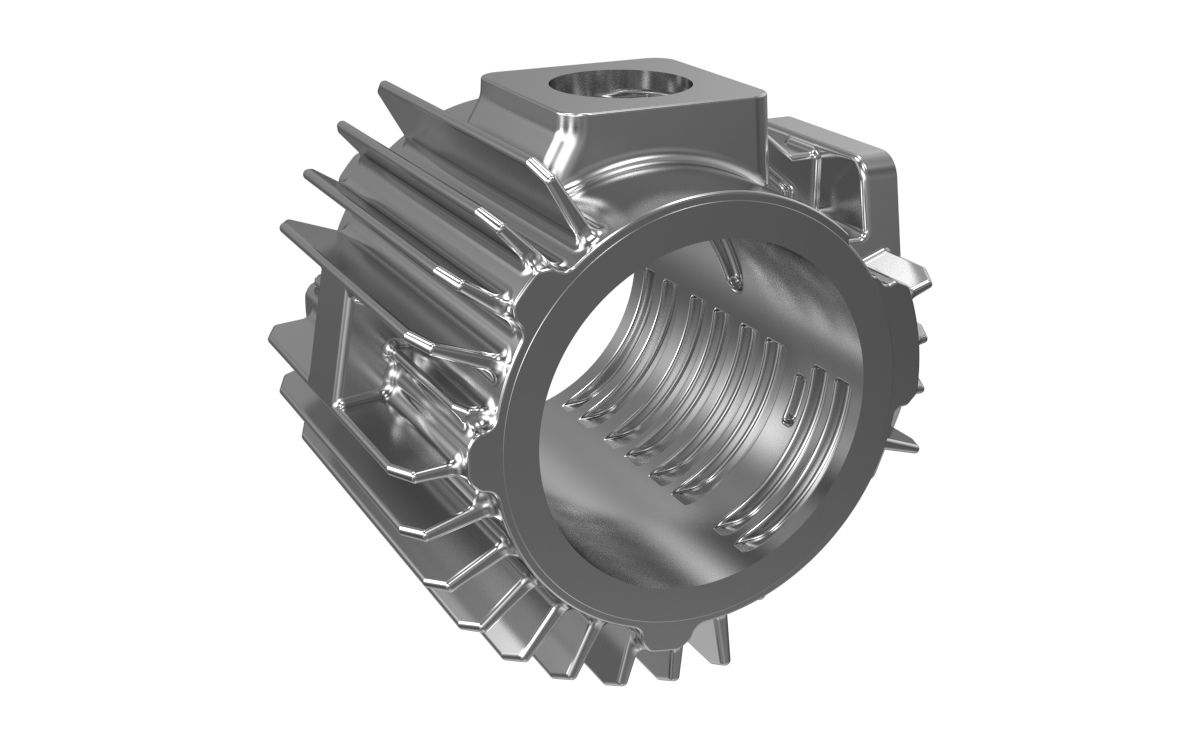

ロータリーベーン真空ポンプのハウジング

EN-GJL-250製ポンプハウジング

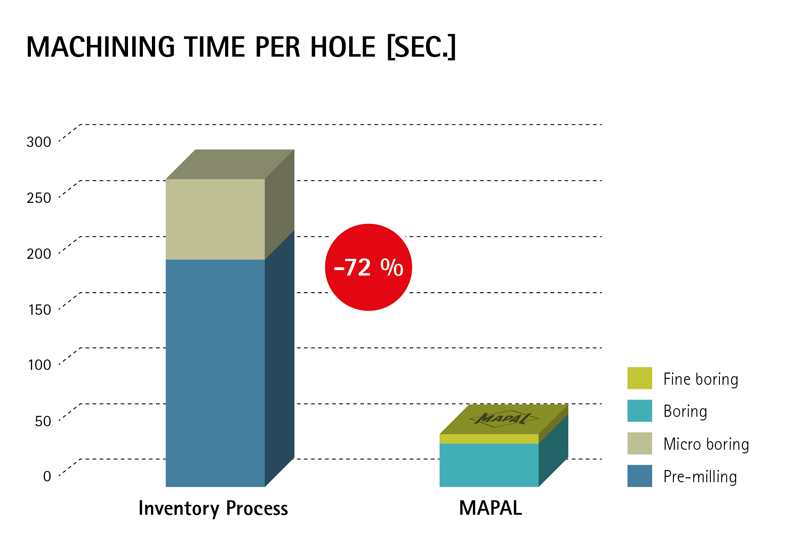

お客様の初期の加工状況

- 需要の大幅な増加と、それに伴う出力の最適化とプロセスの信頼性向上の同時要求

- プレ加工と仕上げスピンドルを使用したステータ穴加工に必要な高い製造労力

ソリューションの特徴

- マルチブレードツールソリューションによる短いサイクルタイムと最大の効率性

- EAシステムによる連続生産工程での容易なハンドリング

- CBNN工具材種の長寿命により、ファインボーリングツールのツールセッティング頻度を低減

- インサートによる工具材料費の低減

- 異なる鋳造材料での複数使用が容易に実現可能

ステータ穴

利点

- マパールツールソリューションにより、サイクルタイムの短縮という形で工程を最適化

- 出力が大幅に向上し、ポンプハウジングの信頼性の高い加工が可能

- スピンドルシステムの省略により、セッティング部品が不要