Produção em grande escala com ferramentas fixas e ajustáveis

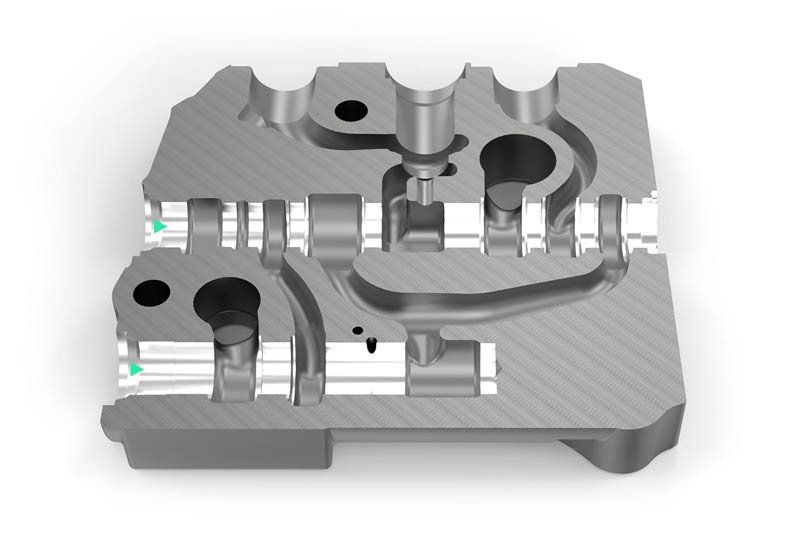

Corpo de válvula EN-GJS-400-15 – Furo do carretel e furo do compensador

Situação inicial no cliente

- Produção em grande escala

- Configuração da ferramenta desejada

- Altas taxas de hora da máquina

- Altos custos para posterior brunimento em passe único

Características especiais da solução

- Ferramentas individuais que combinam perfeitamente umas com as outras garantem, condições prévias ideais para um processo reduzido do brunimento

- O processo de brunimento pode ser eliminado com certos requisitos da peças

Furo do carretel

1. Mandrilamento

- Ótimos resultados na pré-usinagem devido um processo coordenado do furo piloto e do mandrilamento

- Ótimo fluxo de cavacos e possibilidades estendidas de reafiação devido à tecnologia multicorte e perfeito suprimento do refrigerante

- Evita a formação de anéis nas cavidades devido a geometria do furo → sem custos para remoção de anéis

2. Controle na usinagem das bordas

- Ferramenta para mandrilamento de metal duro integral

- Maior precisão e qualidade superficial na usinagem das bordas

- Bordas de controle definidas sem falhas macroscópicas

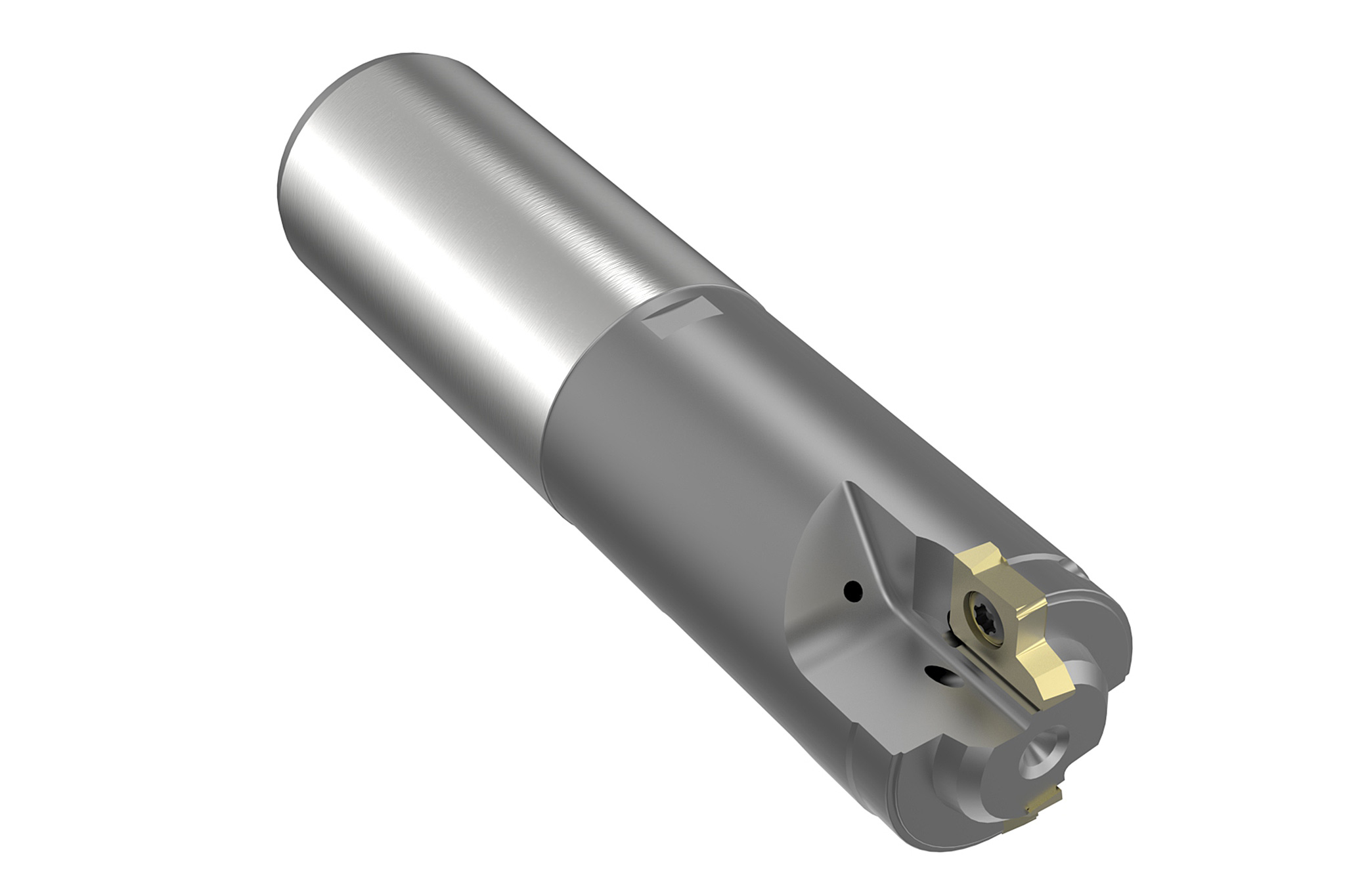

3. Acabamento fino

- Ferramenta para acabamento fino com sistema EasyAdjust e guias

- Usinagem de precisão confiável com fácil manuseio

- As melhores formas cilíndricas devido a ótima orientação

Furo do compensador

1. Mandrilamento

- Ferramenta para mandrilamento de metal duro integral com 6 guias para perfeitas, circularidade e retilinidade

- Furo reto, ideal fluxo de cavaco e orientação em todo o comprimento da furação

- Redução de tempos não produtivos devido a duas operações de usinagem em uma ferramenta

2. Usinagem com controle de borda

- Ferramenta para mandrilamento de duplas facas com geometria especial

- Usinagem confiável do contorno e segurança no processo

- Fácil manuseio com baixo custo de material de corte

3. Acabamento fino

- Ferramenta para acabamento fino com sistema EasyAdjust e guias

- Usinagem fina confiável com fácil manuseio, sem brunimento subsequente

- As melhores formas cilíndricas devido a ótima orientação

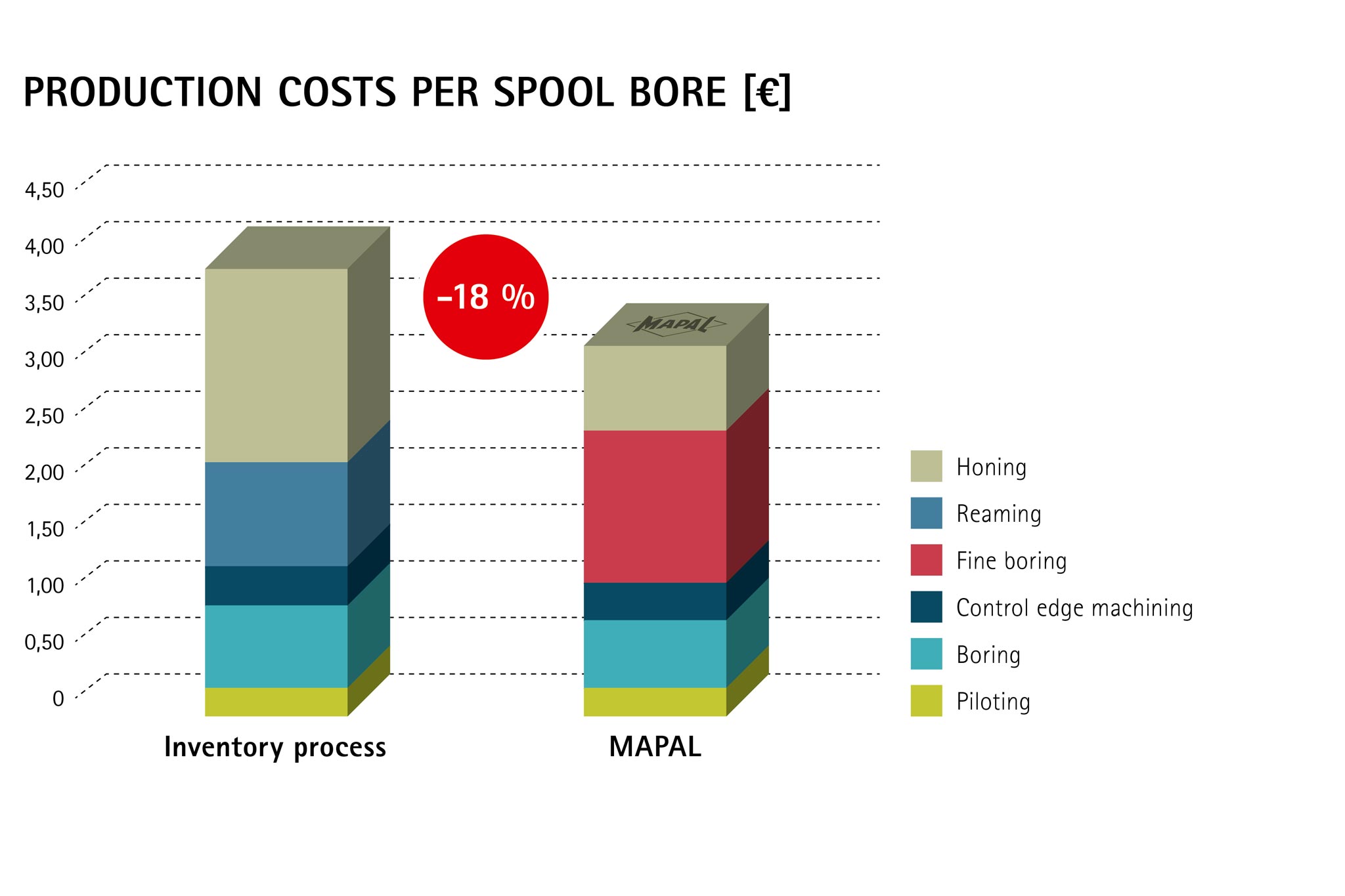

Vantagens

- Processo de brunimento de alto custo no furo do carretel diminuído

- Baixos custos de ferramentas por furo

- Tempos não produtivos mais curtos devido à engenharia inteligente em cooperação com o cliente

- Economia significativa de custos, devido a eliminação do processo de brunimento no furo do compensador

![ANNUAL PRODUCTION COSTS OF THE COMPENSATOR BORE [€]](/medias/sys_master/root/h6c/h6e/9043460718622/Grafiken_EN-13/Grafiken-EN-13.jpg)